What determines the price of an automatic glass cutting line?

The cost of an automatic glass cutting line can vary significantly based on several crucial factors:

Cutting Technology

The type of cutting technology employed in the equipment plays a pivotal role in determining its price. Advanced cutting methods, such as laser cutting or water jet cutting, often come with a higher price tag due to their precision and versatility. Traditional mechanical cutting systems, while less expensive, may not offer the same level of accuracy or speed.

Automation Level

The degree of automation incorporated into the glass cutting line directly impacts its cost. Fully automated systems that require minimal human intervention are typically more expensive than semi-automated or manual alternatives. However, they often provide greater consistency, reduced labor costs, and increased output over time.

Capacity and Size

The size of the glass sheets that can be processed and the overall capacity of the cutting line are significant cost determinants. Larger machines capable of handling oversized glass panels or those designed for high-volume production will generally be more expensive than smaller, lower-capacity systems.

Customization Options

A customized automatic glass cutting line tailored to specific production requirements will typically cost more than a standard model. Customization may include features such as specialized cutting patterns, integration with existing systems, or unique material handling capabilities.

Software and Control Systems

Advanced software and control systems that offer features like optimized cutting patterns, real-time monitoring, and integration with enterprise resource planning (ERP) systems can significantly increase the overall cost of the equipment. However, these features often lead to improved efficiency and reduced waste in the long run.

Brand Reputation and Support

Equipment from well-established manufacturers with a strong reputation for quality and reliability may come at a premium. However, this higher initial cost is often offset by superior performance, longer lifespan, and better after-sales support.

Hidden costs to consider when investing in glass cutting automation

While the initial purchase price of an automatic glass cutting line is a significant consideration, several hidden costs should not be overlooked:

Installation and Setup

The costs associated with installing and setting up the equipment can be substantial. This may include site preparation, electrical work, and specialized rigging or crane services to move and position the machinery.

Training and Skill Development

Investing in operator training is crucial to maximize the potential of your new equipment. This may involve sending staff to the manufacturer's training facility or bringing trainers on-site, both of which incur additional costs.

Maintenance and Spare Parts

Regular maintenance is essential to keep your automatic glass cutting line running smoothly. Factor in the costs of routine maintenance, consumables (such as cutting wheels or fluids), and potential downtime for repairs.

Energy Consumption

Automatic glass cutting lines can be significant energy consumers. Consider the long-term energy costs associated with running the equipment, especially if you're upgrading from less automated systems.

Software Updates and Licensing

If your equipment relies on proprietary software, factor in the costs of ongoing licensing fees and periodic software updates to maintain optimal performance and compatibility.

Facility Modifications

You may need to modify your existing facility to accommodate the new equipment, including changes to layout, ventilation systems, or reinforced flooring to support the weight of the machinery.

Disposal of Old Equipment

If you're replacing existing machinery, consider the costs associated with removing and disposing of the old equipment, which may include environmental compliance fees.

ROI analysis for purchasing an automatic glass cutting system

Conducting a thorough return on investment (ROI) analysis is crucial when considering the purchase of an automatic glass cutting system. Here's a guide to help you evaluate the potential returns:

Quantify Current Costs

Begin by documenting your current production costs, including labor, materials, energy, and maintenance expenses for your existing glass cutting process.

Estimate Productivity Gains

Calculate the potential increase in output that the new automatic glass cutting line could provide. Consider factors such as faster cutting speeds, reduced setup times, and improved material utilization.

Analyze Quality Improvements

Assess the potential reduction in waste and rework due to improved cutting accuracy. Higher quality output can lead to increased customer satisfaction and potentially higher prices for your products.

Labor Cost Savings

Evaluate how automation might impact your labor requirements. While you may need fewer operators, consider the potential need for more skilled technicians to maintain the equipment.

Energy Efficiency

Compare the energy consumption of the new equipment to your current setup. Modern automatic glass cutting lines often offer improved energy efficiency, which can lead to significant cost savings over time.

Maintenance Costs

While new equipment such as a customized automatic glass cutting line may have lower initial maintenance costs, factor in the long-term expenses associated with specialized maintenance and potential downtime for repairs.

Market Opportunities

Consider how the new equipment might allow you to enter new markets or take on more complex projects, potentially leading to increased revenue streams.

Financing Costs

If you're financing the purchase, include the cost of borrowing in your calculations. Compare different financing options to find the most cost-effective solution.

Depreciation and Tax Benefits

Consult with a financial advisor to understand the potential tax benefits of investing in new equipment, including depreciation schedules and potential tax credits for modernizing your production facilities.

Calculate Payback Period

Determine how long it will take for the cost savings and increased revenue to offset the initial investment. A shorter payback period generally indicates a more attractive investment.

Long-term Value

Look beyond the immediate payback period and consider the long-term value the equipment will bring to your business, including improved competitiveness and the ability to meet future market demands.

By carefully considering these factors and conducting a thorough ROI analysis, you can make an informed decision about investing in an automatic glass cutting line. Remember that while the initial cost may be significant, the long-term benefits in terms of efficiency, quality, and competitiveness can make it a worthwhile investment for many glass manufacturers.

Conclusion

Investing in an automatic glass cutting line is a significant decision that requires careful consideration of numerous factors. By understanding the various cost components, hidden expenses, and potential returns, you can make an informed choice that aligns with your business goals and financial capabilities.

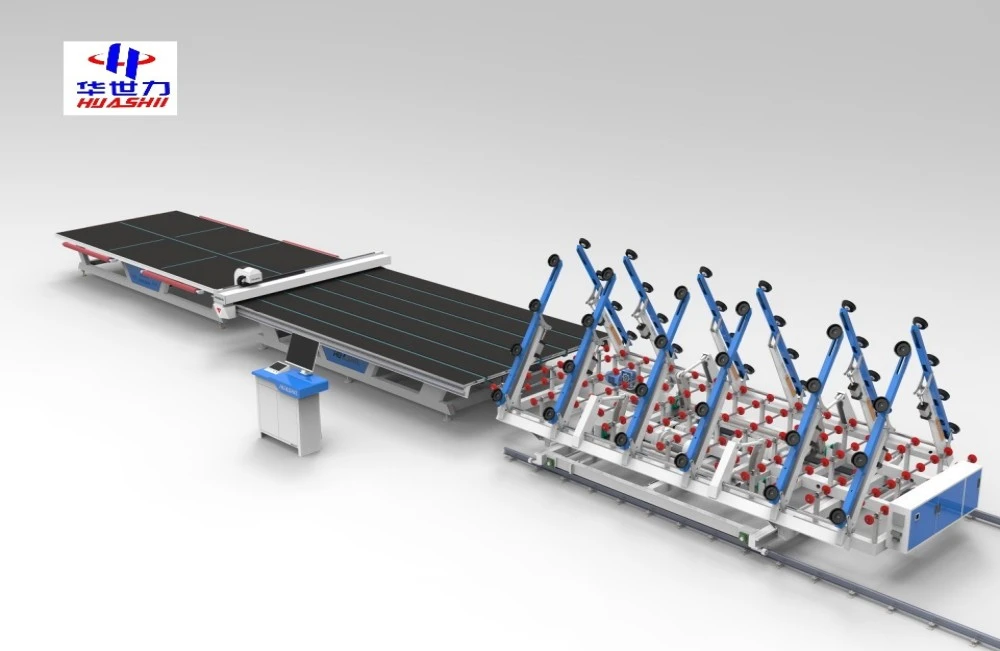

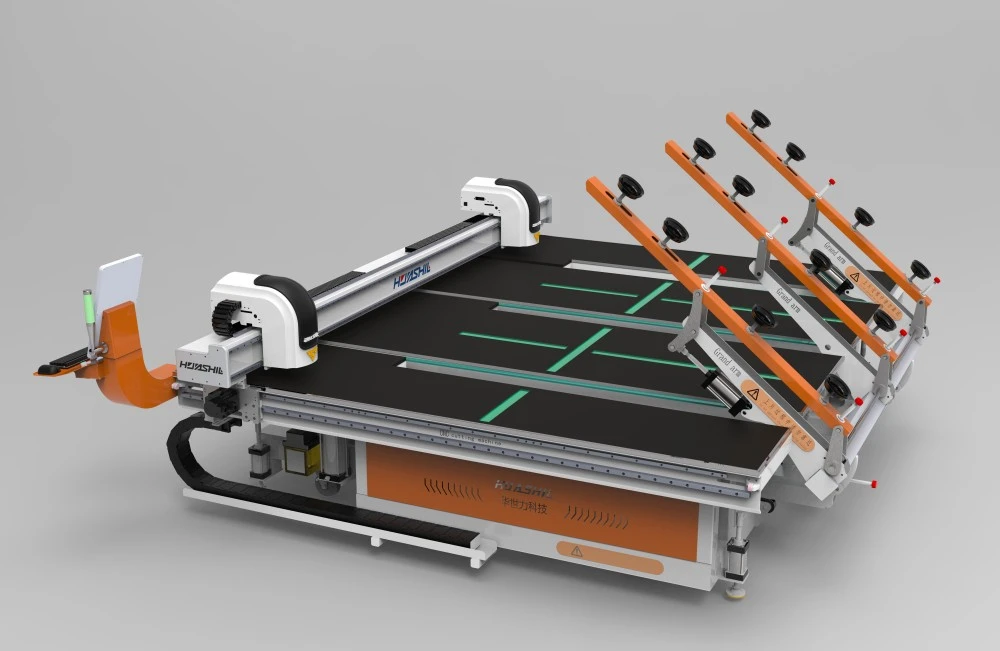

At Shandong Huashil Automation Technology Co., LTD, we specialize in providing cutting-edge automated glass cutting solutions tailored to your specific needs. Our years of experience in production and export, combined with our advanced techniques and commitment to quality, make us the ideal partner for glass manufacturers looking to enhance their production capabilities.

Ready to take your glass cutting operations to the next level? Contact our team of experts today at salescathy@sdhuashil.com to discuss how our automatic glass cutting lines can revolutionize your production process and drive your business forward. Let us help you navigate the complexities of equipment selection and ensure you make an investment that delivers long-term value and competitive advantage.

References

1. Glass Industry Technology Institute. (2023). "Advancements in Automatic Glass Cutting Technologies: A Comprehensive Review."

2. Journal of Industrial Automation. (2022). "Cost-Benefit Analysis of Implementing Automated Glass Cutting Systems in Medium-Scale Enterprises."

3. International Glass Manufacturing Association. (2023). "Hidden Costs and Long-Term ROI Considerations for Automatic Glass Cutting Equipment."

4. Global Glass Technology Forum. (2022). "Future Trends in Glass Cutting Automation: Implications for Equipment Investment Strategies."