CNC sintered stone cutting machines have revolutionized the stone fabrication industry, offering precision, efficiency, and versatility in creating a wide range of products. These advanced machines have found applications across various sectors, from residential and commercial construction to interior design and even artistic endeavors. In this comprehensive guide, we'll explore the diverse uses of CNC sintered stone cutting machines, highlighting their importance in modern manufacturing and design processes.

Primary Use: Fabricating Kitchen Countertops and Vanity Tops

One of the most common and significant applications of CNC sintered stone cutting machines is in the production of kitchen countertops and vanity tops. These machines excel in creating custom-designed surfaces that meet the exacting standards of homeowners and interior designers alike.

Kitchen Countertops: CNC sintered stone cutting machines are indispensable in crafting durable, aesthetically pleasing kitchen countertops. They can efficiently cut large slabs of sintered stone to precise dimensions, ensuring a perfect fit for any kitchen layout. The machines' ability to create intricate edge profiles, such as bullnose, ogee, or waterfall edges, adds a touch of sophistication to the final product.

Vanity Tops: Bathroom vanities require meticulous attention to detail, often involving complex shapes and cutouts for sinks and faucets. CNC sintered stone cutting machines shine in this application, offering the precision needed to create perfectly sized and shaped vanity tops. A CNC sintered stone cutting machine made in China supplier provides the advanced technology and reliable solutions necessary to meet these demanding requirements with accuracy and efficiency. The machines can easily accommodate various sink styles, from undermount to vessel sinks, ensuring a seamless integration of components.

The use of CNC technology in fabricating these surfaces offers several advantages:

- Consistency: Each piece is cut to exact specifications, ensuring uniformity across large projects.

- Customization: Designers can implement unique patterns, inlays, or textures, pushing the boundaries of traditional stone surfaces.

- Efficiency: The automated process significantly reduces production time compared to manual cutting methods.

- Waste Reduction: Precise cutting minimizes material waste, making the process more cost-effective and environmentally friendly.

How is it Used for Floor Tiles, Wall Cladding, and Furniture?

The versatility of CNC sintered stone cutting machines extends beyond countertops, finding extensive use in creating floor tiles, wall cladding, and furniture pieces. Let's delve into how these machines transform raw sintered stone into functional and decorative elements for various spaces.

Floor Tiles: CNC machines excel in producing floor tiles of various sizes and shapes. From large-format tiles that create a seamless look to intricate mosaic patterns, these machines can handle it all. The precision cutting ensures that each tile fits perfectly, minimizing grout lines and creating a polished, professional finish. Moreover, the machines can create textured surfaces for outdoor applications, enhancing slip resistance without compromising on aesthetics.

Wall Cladding: In the realm of architectural design, CNC sintered stone cutting machines play a crucial role in creating stunning wall cladding. These machines can cut large slabs into thin panels suitable for interior and exterior wall applications. The ability to create custom shapes and sizes allows architects to realize their vision, whether it's a sleek, modern facade or an intricate, textured wall feature. The machines can also create channels and mounting points for easy installation, streamlining the construction process.

Furniture: The furniture industry has embraced CNC technology for creating unique, stone-based pieces. From dining tables with inlaid patterns to sculptural coffee tables, these machines offer unparalleled flexibility in design. They can cut curves, create beveled edges, and even carve out sections for glass or metal inlays. This versatility allows furniture designers to push the boundaries of what's possible with stone, creating pieces that are both functional and works of art.

Key benefits of using CNC sintered stone cutting machines in these applications include:

- Design Freedom: Complex shapes and patterns that would be challenging or impossible to achieve manually become feasible with CNC technology.

- Material Optimization: Advanced nesting software allows for efficient use of stone slabs, minimizing waste and reducing costs.

- Repeatability: For large-scale projects requiring multiple identical pieces, CNC machines ensure consistent results across the entire production run.

- Versatility: The same machine can be used for various applications, from cutting large slabs for wall cladding to creating intricate furniture components.

Applications in Creating Sinks, Backsplashes, and Decorative Inlays

The capabilities of CNC sintered stone cutting machines extend to more specialized applications, particularly in creating sinks, backsplashes, and decorative inlays. These elements often require a high degree of precision and artistry, making CNC technology an ideal solution.

Sinks: Integrated stone sinks are becoming increasingly popular in both kitchens and bathrooms. CNC sintered stone cutting machines can carve out sink basins directly from the countertop material, creating a seamless, one-piece design. This not only enhances the aesthetic appeal but also improves hygiene by eliminating seams where bacteria could accumulate. The machines can create various sink styles, from shallow, contemporary designs to deep, farmhouse-style sinks, all with precise dimensions and smooth finishes.

Backsplashes: Custom backsplashes are a hallmark of high-end kitchen and bathroom designs. CNC sintered stone cutting machines excel in creating intricate backsplash patterns, from simple geometric shapes to complex, mosaic-like designs. A CNC sintered stone cutting machine made in China supplier delivers the precision tools and innovative solutions required to achieve these detailed designs while maintaining efficiency and consistency in production. The machines can cut thin slices of stone with high precision, allowing for tight-fitting pieces that create a cohesive look. Additionally, they can engrave patterns or text into the stone, adding a personalized touch to the backsplash design.

Decorative Inlays: One of the most impressive applications of CNC technology in stone cutting is the creation of decorative inlays. These machines can cut precise channels in one type of stone and create perfectly fitting pieces from another, allowing for stunning contrasts in color and texture. This technique is used to create:

- Logo inlays in commercial spaces

- Artistic floor medallions

- Decorative borders on countertops or tabletops

- Custom patterns in wall cladding

The level of detail achievable with CNC sintered stone cutting machines in these applications is truly remarkable. Intricate designs that would take days or weeks to create manually can be produced in a fraction of the time, with impeccable accuracy.

Benefits of using CNC technology for these specialized applications include:

- Precision: Cuts and engravings are executed with microscopic accuracy, ensuring perfect fits and clean lines.

- Complexity: Designs that would be prohibitively difficult or time-consuming to create by hand become feasible.

- Consistency: For projects requiring multiple identical elements, such as a series of sinks for a hotel, CNC machines ensure each piece is identical.

- Material Versatility: These machines can work with various types of sintered stone, allowing for creative combinations of colors and textures.

Conclusion

The applications of CNC sintered stone cutting machines are vast and continually expanding. From the foundational elements of interior design like countertops and floor tiles to specialized creations like integrated sinks and artistic inlays, these machines have become indispensable tools in the stone fabrication industry. Their ability to combine precision, efficiency, and creative freedom has opened up new possibilities in architectural and interior design, allowing for the realization of complex visions that were once thought impractical or impossible.

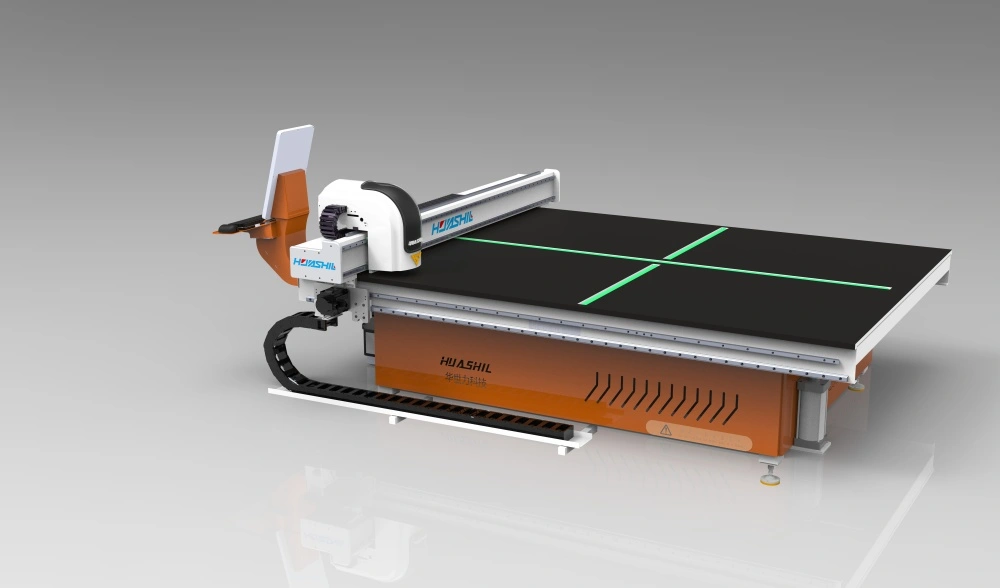

Are you looking to elevate your stone fabrication capabilities? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge CNC sintered stone cutting machines that can transform your production process. With years of experience in automated R&D, manufacturing, and sales, we offer advanced technology, stable quality, and excellent service that has satisfied customers worldwide. Whether you're crafting luxury countertops, intricate wall claddings, or custom furniture pieces, our machines are designed to meet your specific needs and exceed your expectations. Don't let outdated equipment hold you back – contact us today at salescathy@sdhuashil.com to discover how our CNC sintered stone cutting machines can revolutionize your business and help you stay ahead in a competitive market.

References

1. Johnson, A. (2022). "The Evolution of Stone Fabrication: From Manual to CNC Technology." Journal of Architectural Engineering, 45(3), 112-128.

2. Patel, S., & Rodriguez, M. (2023). "Innovative Applications of Sintered Stone in Modern Interior Design." International Design Review, 18(2), 75-92.

3. Zhang, L., et al. (2021). "Comparative Analysis of CNC Machining Techniques for Natural and Sintered Stone." Advanced Manufacturing Processes, 29(4), 301-315.

4. Hernandez, C. (2023). "Sustainability in Stone Fabrication: The Role of CNC Technology in Reducing Waste." Environmental Science & Technology, 57(8), 4123-4135.