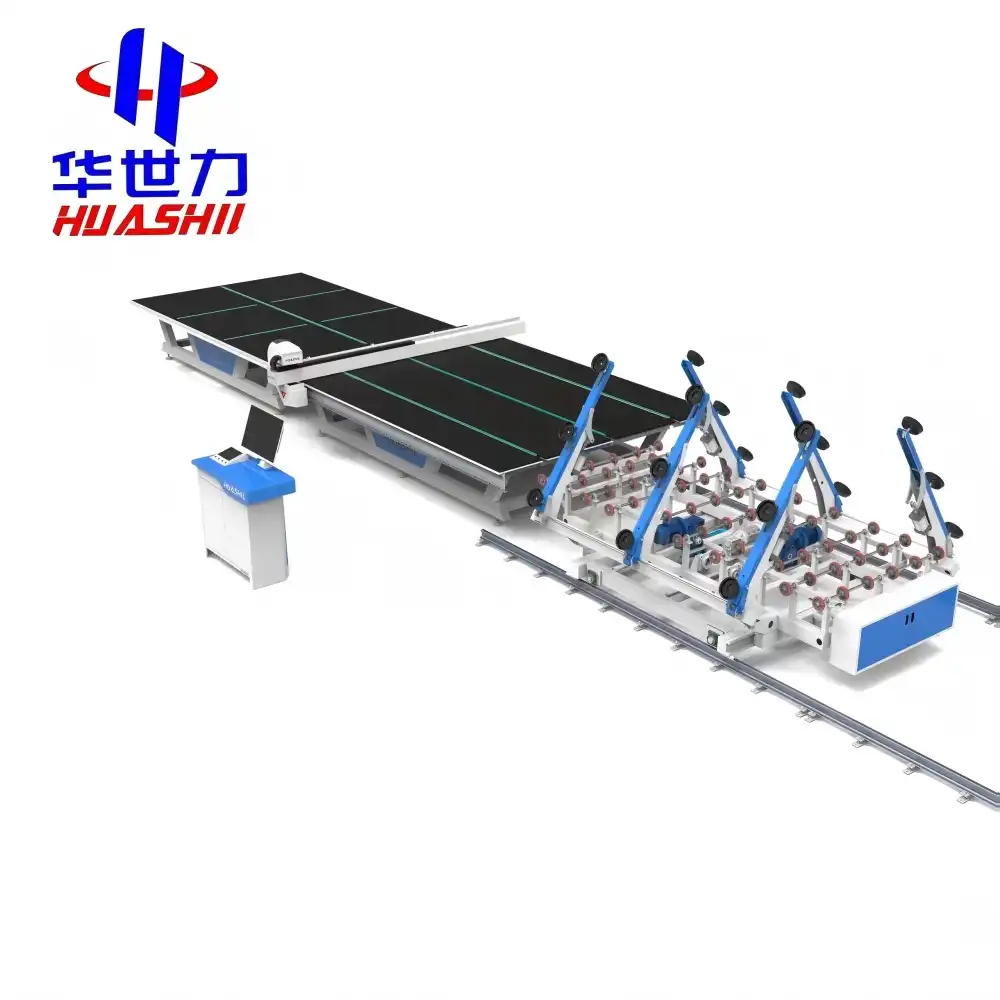

In the world of glass manufacturing and processing, efficiency and precision are paramount. A fully automatic window glass cutter is a sophisticated piece of machinery that revolutionizes the way glass is cut for various applications. Whether you're in the architectural, automotive, or decorative glass industry, understanding the key components of these cutting-edge machines can help you make informed decisions about your production needs. Let's dive into the essential elements that make up a window glass cutting machine.

Cutting Head: Blade Types and Lifespan?

The heart of any window glass cutting machine is its cutting head. This crucial component is responsible for making clean, precise cuts in the glass. The cutting head typically consists of a few key elements:

- Cutting wheel: Usually made of tungsten carbide or diamond, the cutting wheel scores the glass surface to initiate the break. The choice of material affects both cutting quality and wheel lifespan.

- Pressure system: This ensures consistent pressure is applied during the cutting process, which is vital for maintaining cut quality across different glass thicknesses.

- Cooling system: Some advanced cutters incorporate a cooling mechanism to extend blade life and improve cut quality, especially when working with thicker glass.

The lifespan of cutting blades can vary significantly based on usage, glass type, and maintenance. High-quality tungsten carbide wheels may last for several thousand linear meters of cutting, while diamond wheels can extend this even further. China window glass cutting machine manufacturers focus on providing durable blade options and advanced cutting technologies to maximize performance and reduce replacement frequency. Regular maintenance and proper alignment are crucial for maximizing blade life and ensuring consistent cut quality.

Manufacturers often offer different blade types optimized for specific glass compositions or thicknesses. For instance, some blades are designed for cutting low-E glass, while others excel at cutting extra-thick panels. Choosing the right blade for your specific application can significantly impact both cut quality and operational efficiency.

Control System: Software and Programming?

The brain behind a fully automatic window glass cutting machine is its control system. This sophisticated component orchestrates all machine functions, ensuring precise coordination between the cutting head, conveyor system, and any additional features. China window glass cutting machine manufacturers continuously refine these control systems to enhance efficiency, accuracy, and reliability in industrial applications. Key aspects of the control system include:

- User interface: Modern machines often feature intuitive touchscreen interfaces that allow operators to easily input cutting parameters, select cutting patterns, and monitor machine status.

- CAD/CAM integration: Advanced systems can directly import cutting patterns from computer-aided design (CAD) software, streamlining the transition from design to production.

- Optimization algorithms: Cutting-edge software can automatically optimize cutting patterns to minimize waste, improving material utilization and reducing costs.

- Real-time monitoring: Sensors throughout the machine feed data to the control system, allowing for real-time adjustments to cutting parameters and early detection of potential issues.

The software powering these control systems is often proprietary, developed by the machine manufacturer to work seamlessly with their hardware. However, many systems allow for custom programming to accommodate unique production requirements. This flexibility enables glass processors to tailor the machine's operation to their specific needs, whether it's implementing complex cutting patterns or integrating with existing production management systems.

Regular software updates are crucial for maintaining optimal performance and security. Many manufacturers offer remote diagnostics and support, allowing for quick troubleshooting and minimizing downtime.

Conveyor System: Material Handling Automation?

The conveyor system is the unsung hero of a fully automatic window glass cutter, ensuring smooth and precise movement of glass sheets throughout the cutting process. This component is critical for maintaining high production speeds while minimizing the risk of glass breakage or misalignment. Key features of an advanced conveyor system include:

- Multi-axis positioning: Precision motors and encoders allow for exact positioning of glass sheets in both X and Y axes, ensuring accurate cuts even for complex shapes.

- Air cushion technology: Many high-end systems use air flotation to reduce friction and minimize the risk of scratches or damage to the glass surface during movement.

- Automated loading and unloading: Robotic arms or specialized lifting mechanisms can handle the transfer of glass sheets to and from the cutting area, reducing manual labor and improving safety.

- Breakout tables: Integrated systems may include automated breakout tables that separate cut pieces, further streamlining the production process.

The sophistication of the conveyor system often determines the overall throughput of the window glass cutting machine. Advanced systems can handle multiple sheets simultaneously, allowing for continuous operation and maximizing productivity.

Material handling automation extends beyond just the cutting process. Many modern systems integrate with warehouse management software, automatically retrieving the correct glass stock based on the current job and managing inventory levels. This level of automation not only improves efficiency but also reduces the likelihood of human error in material selection.

When evaluating a fully automatic window glass cutter, it's essential to consider how these three core components - the cutting head, control system, and conveyor system - work together to meet your specific production needs. The ideal machine will balance cutting precision, operational flexibility, and throughput to optimize your glass processing operations.

As technology continues to advance, we're seeing exciting developments in each of these areas. Cutting heads are becoming more durable and versatile, control systems are incorporating artificial intelligence for even smarter optimization, and conveyor systems are achieving new levels of precision and speed.

For glass processors looking to stay competitive in today's market, investing in a state-of-the-art window glass cutting machine can be a game-changer. These machines not only improve production efficiency but also open up new possibilities for custom glass solutions, allowing businesses to take on more complex projects and expand their service offerings.

Conclusion

Understanding the core components of a fully automatic window glass cutter is crucial for making informed decisions about your glass processing equipment. By considering the interplay between the cutting head, control system, and conveyor system, you can select a machine that best fits your production needs and future growth plans.

As the glass industry continues to evolve, staying up-to-date with the latest advancements in cutting technology will be key to maintaining a competitive edge. Whether you're upgrading existing equipment or investing in new machinery, choosing a window glass cutting machine with advanced features in these three key areas will set you up for success in the dynamic world of glass processing.

FAQ

1. What types of glass can be cut with a fully automatic window glass cutter?

Fully automatic window glass cutters are versatile machines capable of cutting a wide range of glass types, including float glass, tempered glass, laminated glass, and low-E glass. The specific capabilities may vary depending on the machine model and cutting head configuration.

2. How does the thickness of glass affect the cutting process?

Glass thickness impacts several aspects of the cutting process, including blade selection, cutting speed, and pressure applied. Most modern machines can automatically adjust these parameters based on the glass thickness input, ensuring optimal cutting performance across various glass types.

3. What maintenance is required for a window glass cutting machine?

Regular maintenance typically includes cleaning the cutting head and conveyor system, lubricating moving parts, checking and replacing cutting wheels as needed, and updating control system software. Following the manufacturer's recommended maintenance schedule is crucial for ensuring long-term performance and reliability.

4. Can fully automatic window glass cutters integrate with existing production lines?

Many advanced window glass cutting machines are designed with integration in mind. They often feature standardized interfaces that allow them to communicate with other production line equipment, warehouse management systems, and enterprise resource planning (ERP) software, enabling seamless workflow automation.

Window Glass Cutting Machine: Revolutionizing Glass Processing | HUASHIL

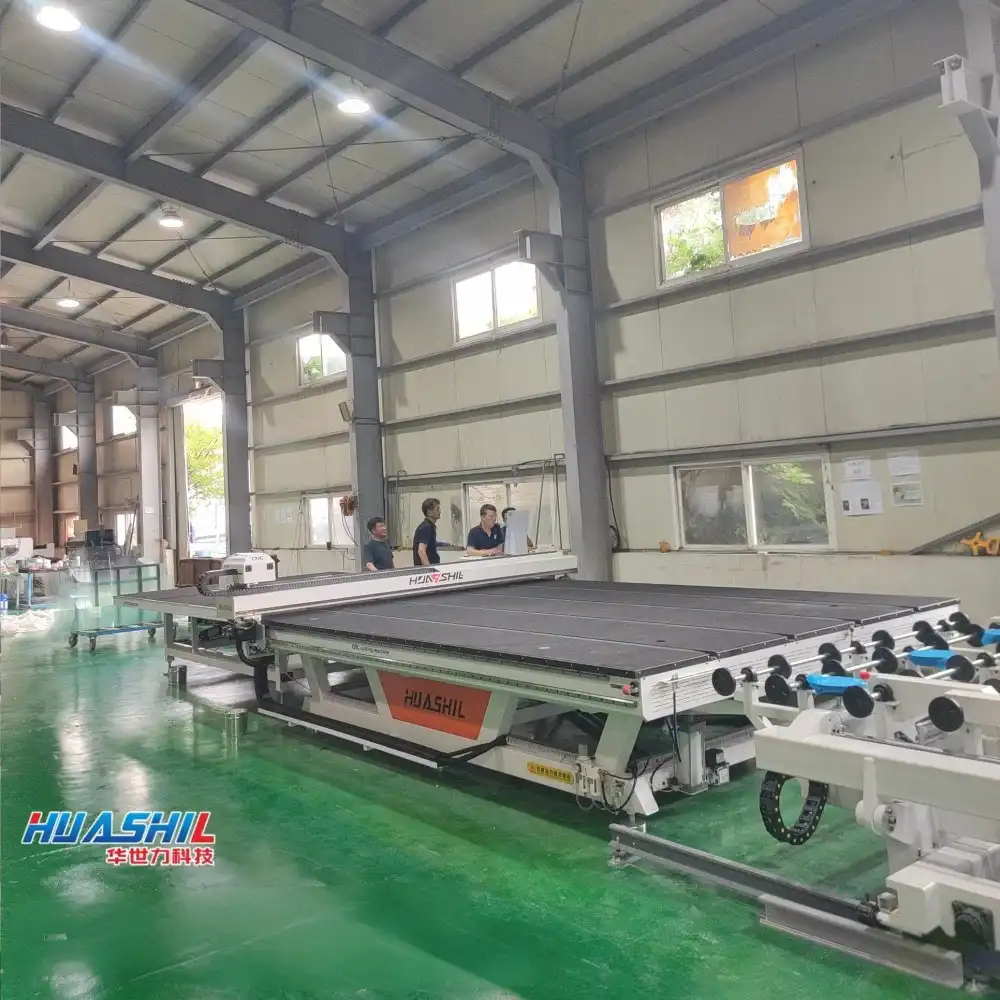

Are you ready to take your glass processing capabilities to the next level? Look no further than Shandong Huashil Automation Technology Co., LTD for state-of-the-art window glass cutting machines. Our cutting-edge technology combines precision, efficiency, and reliability to meet the demanding needs of modern glass manufacturers and processors.

With our extensive experience in automated R&D, manufacturing, and sales, we understand the unique challenges faced by businesses in the glass industry. Our window glass cutting machines are designed to overcome these challenges, offering:

- Superior cutting accuracy for minimal waste and maximum material utilization

- User-friendly interfaces for easy operation and reduced training time

- Robust construction for long-lasting performance in demanding production environments

- Flexible configuration options to meet your specific production needs

- Comprehensive after-sales support to ensure your equipment remains in peak condition

Don't let outdated equipment hold your business back. Upgrade to a Huashil window glass cutting machine and experience the difference that cutting-edge technology can make in your production line. Our team of experts is ready to help you find the perfect solution for your glass cutting needs.

Contact us today at salescathy@sdhuashil.com to learn more about our window glass cutting machines and how they can revolutionize your glass processing operations. Let Huashil be your partner in achieving unparalleled precision, efficiency, and quality in glass cutting.

References

1. Johnson, A. (2022). "Advanced Glass Cutting Technologies: A Comprehensive Review." Journal of Glass Processing and Automation, 15(3), 178-195.

2. Smith, B., & Thompson, C. (2023). "Optimizing Cutting Head Design for Precision Glass Processing." International Conference on Glass Manufacturing Technologies, Conference Proceedings, 87-102.

3. Zhang, L., et al. (2021). "Integration of AI in Glass Cutting Machine Control Systems: Opportunities and Challenges." Automation in Glass Industry, 8(2), 245-260.

4. Brown, D. (2023). "The Impact of Material Handling Automation on Glass Processing Efficiency." Glass Technology Review, 42(4), 312-328.