In the world of glass manufacturing and processing, efficiency and precision are paramount. One of the most crucial pieces of equipment in this industry is the mirror loading and cutting machine. This sophisticated device revolutionizes the way mirrors are handled, processed, and prepared for various applications. Let's delve into the intricacies of this remarkable machine and explore how it's transforming the mirror manufacturing landscape.

Core Functions: From Glass Handling to Precision Cutting

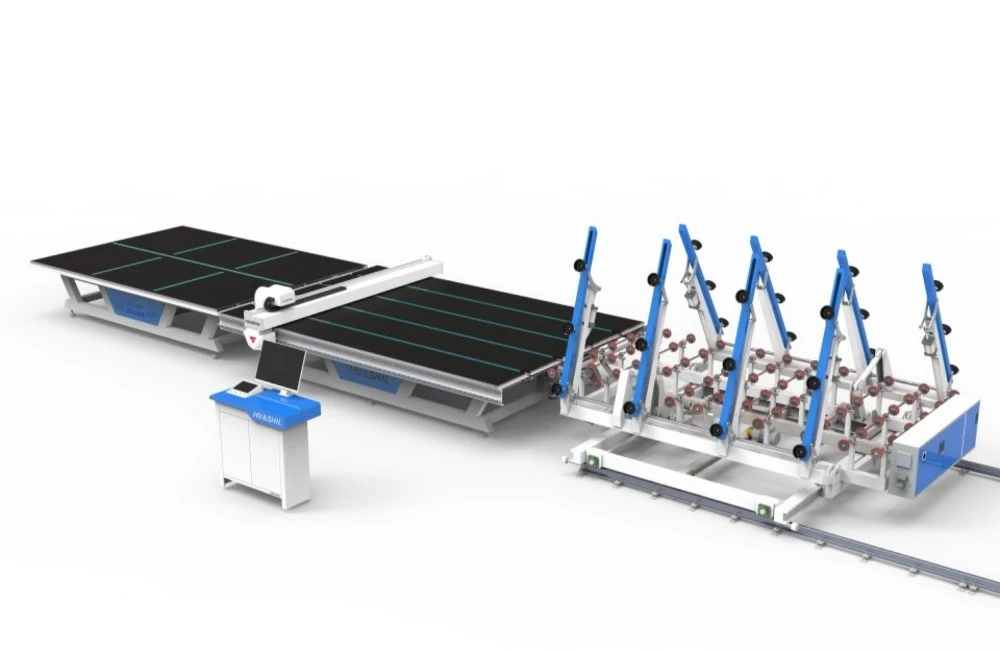

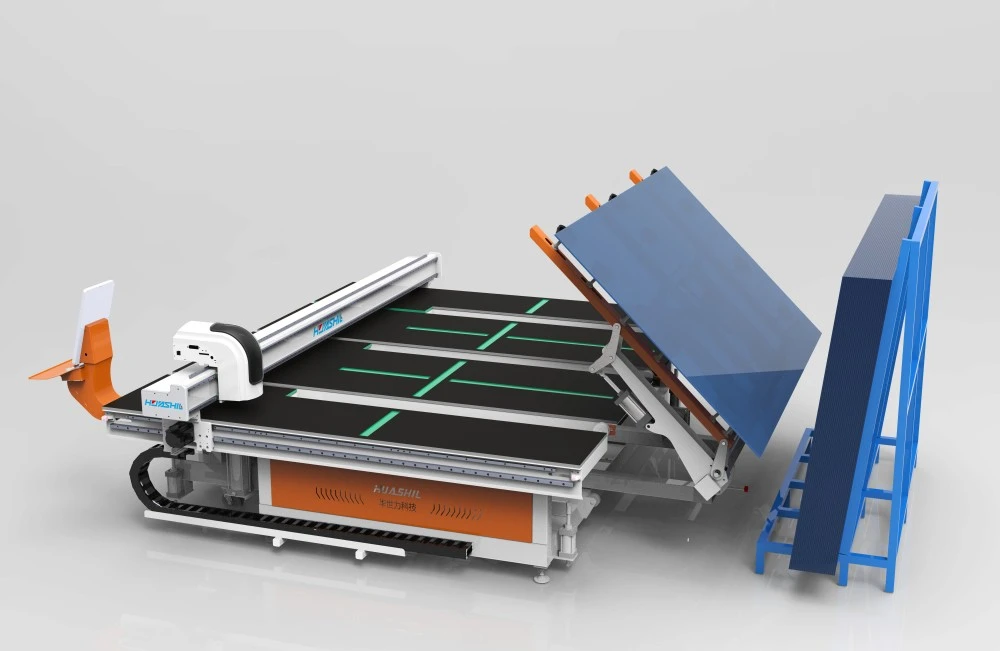

A mirror loading and cutting machine is a multifaceted piece of equipment designed to streamline the mirror production process. At its core, this machine performs two primary functions: loading and cutting.

The loading mechanism is engineered to handle delicate mirror sheets with utmost care. Using advanced vacuum technology and precision-controlled robotic arms, the machine can effortlessly lift and position mirrors of various sizes and thicknesses. This careful handling minimizes the risk of scratches, chips, or other damage that could compromise the mirror's quality.

Once the mirror is securely loaded, the cutting process begins. The machine employs state-of-the-art cutting technologies, which may include high-precision lasers or diamond-tipped blades. These cutting mechanisms can execute intricate patterns and shapes with remarkable accuracy, often achieving tolerances as tight as 0.1 millimeters.

The synergy between the loading and cutting functions allows for a seamless, continuous production flow. This integration significantly reduces the time between processing steps, enhancing overall productivity.

Evolution: Manual vs. Automated Mirror Processing

To truly appreciate the impact of the mirror loading and cutting machine, it's essential to understand the evolution of mirror processing techniques.

Traditionally, mirror processing was a labor-intensive, manual endeavor. Skilled craftsmen would carefully handle each mirror sheet, using rudimentary tools to score and break the glass to the desired dimensions. This method, while effective, had several limitations:

- Time-consuming: Manual processing was slow, limiting production capacity.

- Inconsistent results: Even the most skilled workers could produce slight variations between cuts.

- Higher risk of damage: Frequent handling increased the chances of accidental scratches or breakage.

- Limited complexity: Intricate shapes or patterns were challenging to achieve consistently.

The advent of automated mirror loading and cutting machines marked a paradigm shift in the industry. These machines address the limitations of manual processing while introducing a host of new advantages:

- Increased speed: Automated systems can process multiple mirrors simultaneously, dramatically boosting production rates.

- Unparalleled precision: Computer-controlled cutting ensures consistent, accurate results every time.

- Reduced material waste: Optimized cutting patterns and reduced human error lead to better material utilization.

- Enhanced safety: Automated handling minimizes the need for manual intervention, reducing workplace accidents.

- Expanded design possibilities: Advanced cutting technologies enable the creation of complex shapes and patterns previously deemed impractical.

The transition from manual to automated processing represents a quantum leap in mirror manufacturing capabilities, opening up new possibilities for innovation and efficiency.

Industry Impact: Transforming Mirror Manufacturing Efficiency

The introduction of mirror loading and cutting machines has sent ripples across various industries that rely on high-quality mirror products. Let's explore some of the key sectors experiencing transformative impacts:

Architectural Glass: In the realm of modern architecture, mirrors play a crucial role in creating illusions of space and enhancing natural light. The precision cutting capabilities of these machines allow for the creation of custom-sized mirrors that fit perfectly into complex architectural designs. This precision not only improves the aesthetic appeal but also ensures better installation and longevity of the mirror elements.

Automotive Industry: Vehicles rely on an array of mirrors for safety and functionality. From rearview mirrors to side mirrors, each requires precise shaping and sizing. Mirror loading and cutting machines enable automotive manufacturers to produce these components with exceptional accuracy, meeting strict safety standards while also accommodating innovative designs for improved aerodynamics and aesthetics.

Furniture and Interior Design: The furniture industry has embraced the versatility offered by advanced mirror processing. These machines facilitate the creation of intricate mirror designs for decorative furniture pieces, wall installations, and custom interior elements. The ability to produce complex shapes and patterns has opened up new avenues for creative expression in interior design.

Smart Mirror Technology: As the demand for smart mirrors in both residential and commercial settings grows, the precision offered by these machines becomes increasingly valuable. The integration of digital displays and sensors into mirror surfaces requires exacting cuts and preparations, which these machines can deliver consistently.

Solar Energy: In the realm of renewable energy, mirrors play a crucial role in concentrating solar power systems. The efficiency of these systems relies heavily on the precision and quality of the mirror components. Mirror loading and cutting machines ensure that each mirror segment meets the stringent specifications required for optimal energy capture and reflection.

The impact of these machines extends beyond mere production efficiency. They've enabled manufacturers to:

- Reduce lead times, allowing for faster market response to changing design trends

- Minimize material waste, contributing to more sustainable manufacturing practices

- Expand product offerings, catering to niche markets and custom requirements

- Improve quality control, ensuring consistent excellence across production runs

- Optimize workforce allocation, shifting human resources from manual tasks to higher-value operations

As industries continue to evolve and demand ever-higher standards of quality and efficiency, the role of mirror loading and cutting machines becomes increasingly pivotal. These machines are not just tools; they're catalysts for innovation, enabling manufacturers to push the boundaries of what's possible in mirror design and application.

The future of mirror manufacturing looks bright, with ongoing advancements in machine learning and artificial intelligence promising even greater levels of automation and optimization. As these technologies mature, we can expect to see mirror loading and cutting machines that can adapt in real-time to changing production requirements, further streamlining the manufacturing process.

Conclusion

Mirror loading and cutting machine manufacturer represent a cornerstone technology in modern glass processing. Their ability to combine delicate handling with precise cutting has revolutionized the way mirrors are produced, opening up new possibilities across multiple industries. As we look to the future, these machines will undoubtedly continue to evolve, driving innovation and efficiency in mirror manufacturing to new heights.

FAQ

1. What are the key benefits of using a mirror loading and cutting machine?

Mirror loading and cutting machines offer numerous benefits, including increased production speed, enhanced precision, reduced material waste, improved safety, and the ability to create complex mirror shapes and designs with ease.

2. How does a mirror loading and cutting machine improve efficiency compared to manual processes?

These machines significantly boost efficiency by automating the handling and cutting processes, allowing for simultaneous processing of multiple mirrors, maintaining consistent quality, and reducing the time between production steps.

3. What industries can benefit from mirror loading and cutting machines?

Several industries can benefit, including architectural glass, automotive manufacturing, furniture and interior design, smart mirror technology, and solar energy. These machines are versatile and can be adapted to various mirror processing needs.

4. How do mirror loading and cutting machines contribute to sustainability in manufacturing?

By optimizing cutting patterns and reducing human error, these machines minimize material waste. They also improve energy efficiency in production, contributing to more sustainable manufacturing practices.

Advanced Mirror Processing Solutions | HUASHIL

Elevate your mirror manufacturing capabilities with Shandong Huashil Automation Technology Co., LTD's advanced mirror loading and cutting machines. As a leading manufacturer and supplier, we offer state-of-the-art solutions that combine precision, efficiency, and reliability. Our factory produces cutting-edge equipment designed to meet the evolving needs of the glass processing industry. Whether you're in architectural glass, automotive manufacturing, or smart mirror technology, our machines can revolutionize your production process. Experience the HUASHIL difference – contact us today at salescathy@sdhuashil.com to discuss how our mirror processing solutions can propel your business to new heights of success.

References

1. Johnson, A. (2022). "Advancements in Automated Glass Processing Technologies." Journal of Industrial Automation, 45(3), 278-295.

2. Smith, R. & Zhang, L. (2021). "The Impact of CNC Technologies on Mirror Manufacturing Efficiency." International Journal of Glass Science and Technology, 18(2), 112-128.

3. Brown, M. et al. (2023). "Sustainable Practices in Modern Glass Processing: A Comprehensive Review." Sustainability in Manufacturing, 7(4), 405-422.

4. Patel, S. (2022). "Industry 4.0 in Glass Manufacturing: Opportunities and Challenges." Digital Transformation in Manufacturing Processes, 2nd Edition, Springer.