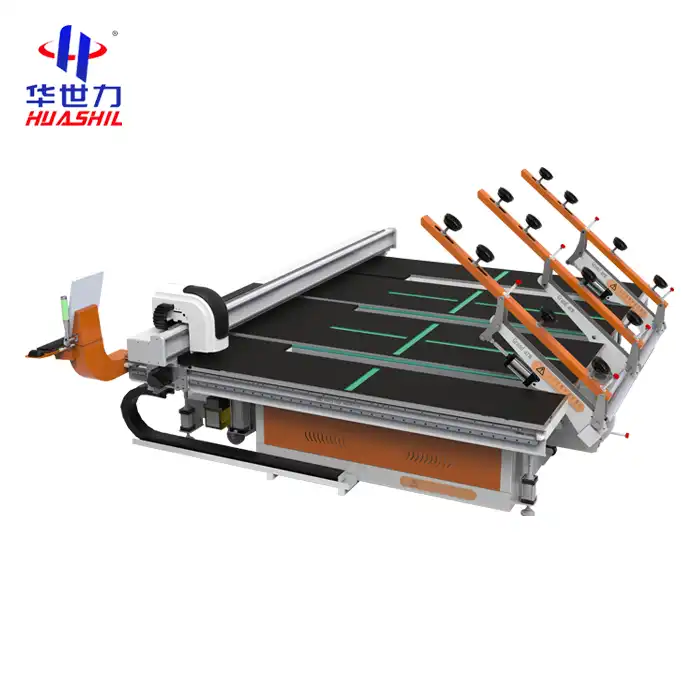

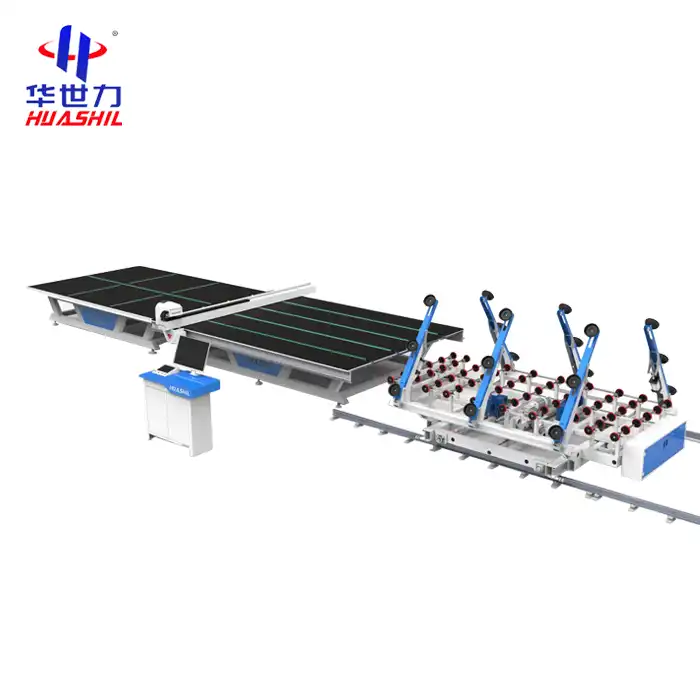

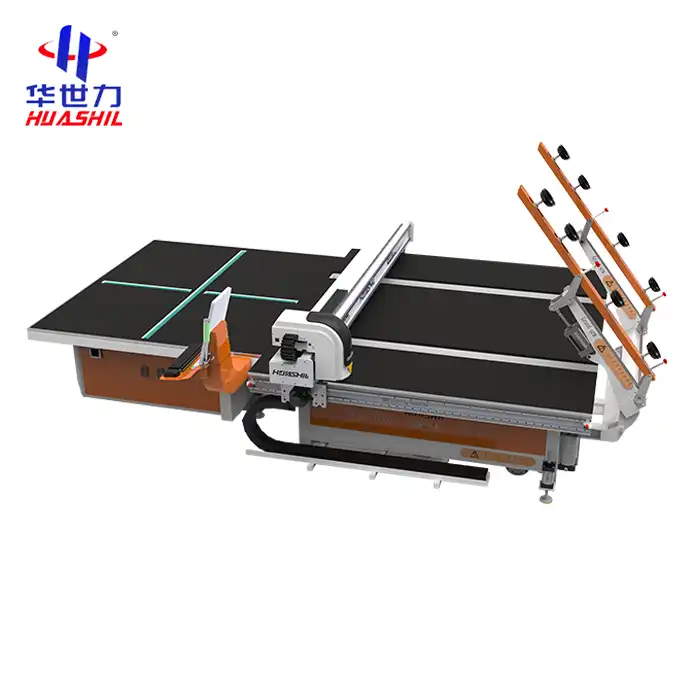

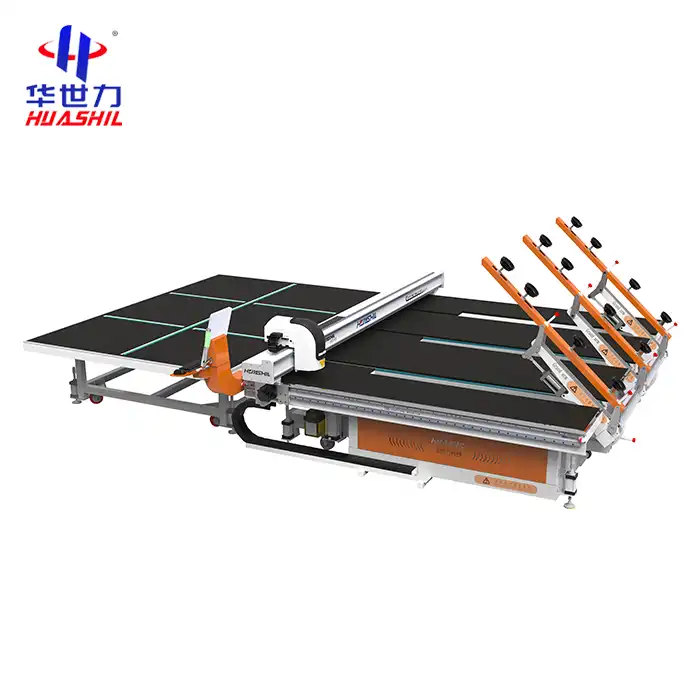

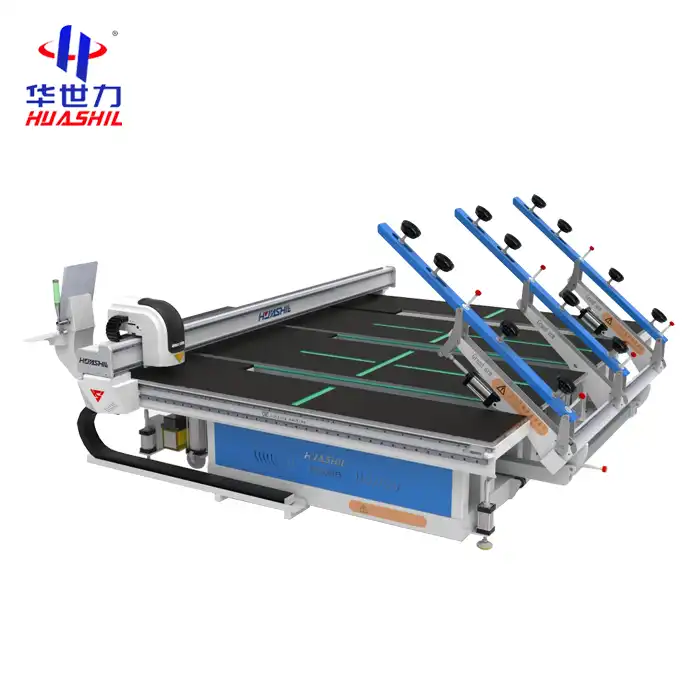

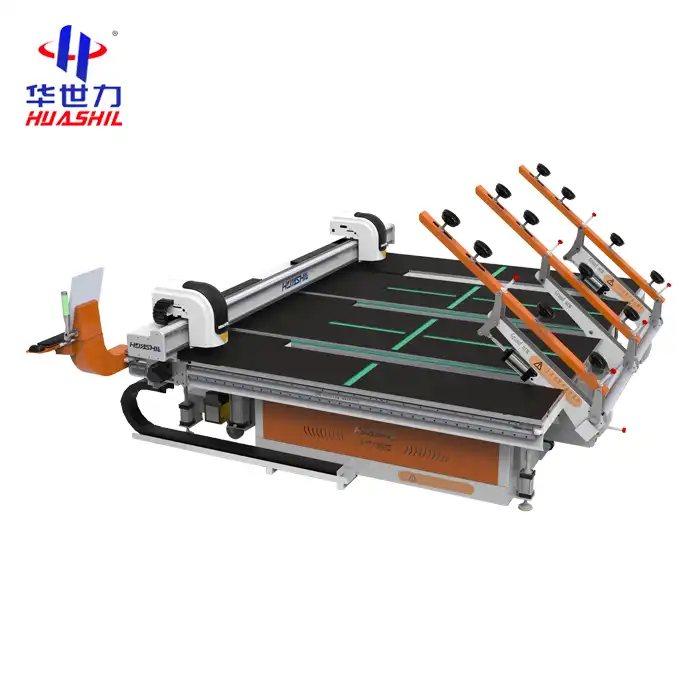

Float glass cutting equipment

2.Max glass size:3660*2440*mm

3.Glass cutting thickness:2-19mm

4.Dimension:5550*4925mm

5.Optimization software:Optima

6.Function: automatic loading,automatic pressure control,automatic edge finding,air flotation system, with breaking table,360 degree remote control walking

7.Certificate:CE, ISO9001 8.Glass conveying by synchronous belts

- Product Description

Float Glass Cutting Equipment: HSL-YTJ3826 by Huashil Machine

Huashil Machine is a leading manufacturer and supplier of float glass cutting equipment, specializing in high-quality solutions like the HSL-YTJ3826. Our cutting-edge technology combines precision, efficiency, and reliability to meet the diverse needs of the glass industry. Huashil's float glass cutting equipment stands out for its advanced features, durability, and exceptional performance.

Functions & Features:

|

|

Cutting technology and automatic oil supply Professional glass cutting control system realizes automatic cutting of straight and special-shaped glass, greatly improving glass cutting efficiency. The pressure of the cutting head is controlled by an electromechanical precision pressure valve. The uniform output pressure of the cylinder allows the cutting head to perfectly fit the glass surface for cutting, thus avoiding the cutting skipping phenomenon caused by glass quality problems . When cutting glass, the cutting oil is automatically filled using pneumatic pressure control, and moves synchronously with the cutting head through the PLC control system . |

|

|

Optimization software and special-shaped libraries Compatible with the standard G code of Italian OPTIMA optimization software and domestic Guiyou software: achieving versatility in processing files in different formats. Glass cutting optimization program is specially designed to cut flat glass into workpieces of different sizes, improving the cutting rate of glass and reducing the waste of original glass sheets. The special-shaped glass cutting library integrates various special-shaped glass patterns and templates to meet the needs of different glass cutting. |

|

|

Automatic edge positioning and intelligent special-shaped scanning Automatic edge-finding and positioning of glass: Accurately detects the actual position and deflection angle of the glass, and automatically adjusts the cutting path of the cutter head to improve efficiency. Intelligent special-shaped scanning: The detector can intelligently scan special-shaped templates and feedback to automatically generate graphics. The templates can be made of various types of materials to achieve profiling cutting. |

|

|

Air floating countertop Cutting table and breaking table are equipped with air holes, and centrifugal fans provide high-pressure airflow to facilitate the transportation or shifting of glass while preventing scratches on the table. |

|

|

Glass conveying After glass cutting, glass is transported to the air flotation breaking table through three synchronous conveying belts and the air flotation system for breaking operations. |

|

|

Automatic rail lubrication glass cutting machine guide rail automatic lubrication system can realize automatic lubrication, reduce manual intervention, and improve the stability and reliability of lubrication. Lubrication reminder can be set. When lubrication is needed, press the oil filling button for 10 seconds to complete the operation, which is easy to operate. |

|

|

Servo motor direct drive structure It adopts servo motor direct drive structure, which is directly driven by X and Y axis servo motors without using belts. With high precision and low noise, it is the preferred structure for high-end CNC equipment. |

|

|

Automatic voltage control Automatic pressure control system uses a high-precision pressure regulating valve to control the pressure of the cutting head. The cutting pressure is evenly output, making it easy to break the slices. When cutting glass of different thicknesses, there is no need to manually adjust the pressure. The cutting system matches the corresponding pressure according to the optimized thickness of the original glass sheet, which is easy to operate. |

|

|

Voltage detection Voltage detection can display the voltage condition during operation in real time, and cooperate with the machine's alarm system to easily monitor the machine's working condition .

|

|

|

Automatic labeling Replace manual labeling. The printer automatically prints out a label recording the glass information, and the fingers of the labeling cylinder grab the label and stick it on the surface of the corresponding glass piece. The standard machine head for labeling has high labeling efficiency. (Customers are recommended to configure the labeling function ) Labels can be set with multiple contents, such as: glass size, customer information, serial number, process, QR code, etc. |

|

|

High performance LOW-E film removal device The width of the film removal wheel used to remove the low-e layer is 20 mm or 25 mm (please note clearly when placing an order) . It has an automatic dust removal function. The dust removal function is automatically turned on after the film removal function is turned on . It has an automatic compensation function and a precision pressure reducing valve controls the pressure of the grinding wheel. There is no need to adjust the film removal depth during use. Can remove rectangular and special shapes. |

Why Choose Huashil?

-

10+ Years Expertise: Trusted by global clients in 30+ countries.

-

OEM/ODM Support: Customize machine specs for your production line.

-

Fast Delivery: Shipped within 15–30 days after order confirmation.

-

Smart Factory Ready: IoT-enabled for real-time efficiency tracking.

-

CE & ISO Certified: Compliant with international safety standards.

Key Features & Benefits

✔ Automatic Edge Finding: ±0.1mm precision for flawless cuts.

✔ Air Flotation System: Prevents glass surface scratches.

✔ 360° Remote Control: Safe, ergonomic operation.

✔ Breaking Table Integration: Streamlines scoring and snapping.

✔ Optima Software: Reduces material waste by up to 20%.

Product Parameters

| Feature | Specification |

|---|---|

| Cutting Thickness | Up to 19mm |

| Precision | ±0.2mm |

| Maximum Cutting Speed | 200m/min |

| Automation Level | Fully Automated |

| Power Requirement | 380V, 50Hz |

| Operating Temperature | -10°C to 45°C |

| Dimensions (L x W x H) | 5550mm x 4925mm x 1600mm |

Product Details

The HSL-YTJ3826 float glass cutting equipment is designed for precision and efficiency in various glass processing applications. Its advanced features ensure high-quality cuts and optimized production workflows.

Quality Control

Huashil Machine maintains strict quality control measures throughout the manufacturing process. We provide mechanical test reports and offer video factory inspections to ensure transparency and build trust with our clients.

Customization Options

Our product can be customized to meet specific requirements, including machine color and additional features tailored to your production needs.

Certification

The HSL-YTJ3826 is CE and ISO9001 certified, demonstrating our commitment to international quality and safety standards.

After-Sales Service

Huashil Machine offers comprehensive after-sales support, including installation guidance, operator training, and prompt technical assistance to ensure optimal equipment performance.

Packaging

Our product is securely packaged to ensure safe transportation and delivery to your facility.

Company Introduction

Huashil Machine is a pioneer in the glass processing industry, focusing on innovative solutions that drive efficiency and quality in float glass cutting operations.

Our Factory

Our state-of-the-art manufacturing facility employs the latest technologies and rigorous quality control processes to produce top-tier product.

Successful Cases

We have numerous success stories of clients achieving improved productivity and reduced waste using our HSL-YTJ3826 product.

Exhibitions

Huashil Machine regularly participates in international trade shows to showcase our latest product innovations.

FAQ

Q: What is the warranty period for the HSL-YTJ3826?

A: We offer a standard one-year warranty on all our product.

Q: Can the machine handle different glass types?

A: Yes, the HSL-YTJ3826 is versatile and can process various glass types, including architectural, coated, and automotive glass.

Q: How does the Optima software improve cutting efficiency?

A: Optima optimizes cutting patterns to maximize yield and minimize waste, significantly improving overall production efficiency.

Q: Is operator training provided with the purchase?

A: Yes, we offer comprehensive training to ensure your team can operate the float glass cutting equipment effectively.

Q: What is the typical lead time for the HSL-YTJ3826?

A: Lead times vary based on customization requirements, but we strive for fast delivery to meet your production needs.

Contact Us

For more information about our product or to request a quote, please contact us at salescathy@sdhuashil.com. Experience the Huashil difference in float glass cutting technology today!

YOU MAY LIKE

-

VIEW MOREGlass cutting table

VIEW MOREGlass cutting table -

VIEW MORE3829 glass cutting machine

VIEW MORE3829 glass cutting machine -

VIEW MOREMirror loading and cutting machine

VIEW MOREMirror loading and cutting machine -

VIEW MORECNC Glass Loading Cutting Breaking machine

VIEW MORECNC Glass Loading Cutting Breaking machine -

VIEW MOREWindow glass cutting machine

VIEW MOREWindow glass cutting machine -

VIEW MOREFurniture cabinet glass cutting machine

VIEW MOREFurniture cabinet glass cutting machine -

VIEW MORECutting machine for stained glass windows

VIEW MORECutting machine for stained glass windows -

VIEW MOREGlass cutting table machine

VIEW MOREGlass cutting table machine