Architectural glass manufacturing and artistic glass creation require precise tools that get the job done right every time and don't slow down production. For makers who want to improve their cutting precision, minimize material waste, and expand their businesses, purchasing a good stained glass cutting machine is an important step. Modern glass cutting systems use high-tech robotics, precise cutting tools, and easy-to-use interfaces that turn old glass workshops into efficient production facilities. Whether you are updating old equipment or setting up new production lines, knowing the most important features, specs, and things to think about when buying will help you choose the best cutting solution for your needs.

Understanding Modern Glass Cutting Technology

Today's tools for cutting glass are much more advanced than the old-fashioned way of marking glass by hand. Modern systems combine computer-controlled accuracy with heavy-duty parts to provide great cutting quality for all kinds of glass, no matter the thickness. These tools always make clean, precise cuts. They use diamond-tipped cutting wheels, air-powered brakes, and sophisticated positioning systems.

Smart sensors that instantly change cutting pressure based on how thick and what kind of glass is being used have now been added to stained glass cutting machine glass manufacturing equipment. This smart method lowers the risk of forming micro-cracks and makes sure that the edges are as good as possible. A lot of systems have flexible designs that let you change them based on the needs of the project, whether it's a small arts project or a highly architectural application.

Integrating CAD software makes it possible to import design files right away, which makes the process from idea to finished product easier. This new piece of technology makes things easier for architectural glass makers and curtain wall builders who work with very exact measurements and complicated shapes.

Key Features That Drive Production Efficiency

How efficient production is rests a lot on the speed of cutting, how reliable the machines are, and how much of the process is automated. Multi-axis advanced glass cutting systems make it possible to place both X and Y axes at the same time while keeping the cutting depth the same. This teamwork greatly shortens the time needed for each step compared to systems that can only move in a straight line.

Systems that automatically load and unload glass in a stained glass cutting machine cut down on the handling that needs to be done by hand. This saves money on labor costs and makes the workplace safer. Adding conveyors to your setup allows work to be done without stopping, which is very useful for places that make a lot of products. Automatic edge cleaning is built into some systems, which gets rid of the need for extra steps.

Precision positioning devices use linear encoders and servo motors to get accuracy within ±0.1 mm. This level of accuracy meets strict design requirements and lowers material waste by using the best cutting patterns. Energy-efficient designs include intelligent power management and drives that can change speed. These features lower the cost of running the equipment over its lifetime.

Material Compatibility and Cutting Capabilities

Today, stained glass cutting machines and glass manufacturing machines work with a variety of materials, not just clear glass. Each type of glass—tempered, laminated, low-E treated, and decorative—has its own cutting challenges that need special methods to be solved. Understanding material suitability makes sure that all of your products work as well as they can.

The thickness of the material can usually be anywhere from 2mm to 25mm, so it can be used for anything from fine decorative pieces to structural glass. Some systems come with cutting heads that can be swapped out for ones that are designed for certain thickness ranges. This gets the best quality cut and also makes the tool last longer.

When it comes to glass art, edge quality and cutting accuracy are very important. Specialized scoring wheels and breaking devices keep colored and textured glass surfaces intact. Temperature control systems stop thermal stress during cutting. This is very important for keeping high-end applications' visual clarity.

Automation Levels and Integration Options

Glass automation options include everything from semi-automatic systems that need help from a technician to production lines that are fully automated. Semi-automatic machines are a great choice for medium-volume jobs because they combine hand loading with automated cutting processes. These tools allow you to do things in different ways and don't take as much work as doing things by hand.

Fully automatic stained glass cutting machine lines combine moving, cutting, breaking, and sorting of materials into one smooth process. These all-in-one systems are good for producers who make a lot of products and want to keep output steady while minimizing the role of workers. Real-time production control and quality tracking are possible because of the integration with ERP systems.

As output increases, customizable automation tools make it possible for the system to grow over time. Modular designs let you add features like automatic quality checking, packing, or labeling without having to replace the core parts that do the cutting. This flexibility allows the business to grow and saves the value of long-term investments at the same time.

Quality Control and Precision Standards

Quality assurance systems use built-in sensors and measurement tools to keep an eye on how well cutting is done. Real-time input lets you make changes right away, which keeps the edge quality the same during all production runs. Statistical process control keeps track of cutting accuracy trends, which makes it easier to plan repairs before they need to be done.

Edge quality inspection measures chipping, straightness, and surface finish. Advanced systems automatically reject pieces that don't meet the standards. This keeps quality high while lowering the need for human review. Vision systems can find flaws that humans can't see, which improves total quality control.

Calibration methods make sure that the quality is kept up over time in stained glass cutting machine systems. Automated calibration processes make sure that the placement and cutting force are both correct and consistent. For architectural and safety glass uses, it is very important to keep good records in documentation systems that meet tracking needs.

Installation, Training, and Ongoing Support

Professional installers make sure that the machine works perfectly from the very beginning. Electrical links, pneumatic systems, and software setup are taken care of by experts with a lot of experience. Before production starts, comprehensive testing makes sure that all functions meet standard requirements.

Operator training classes teach people how to run machines, fix them when they're broken, and do routine maintenance. People become more confident and skilled when they are trained with real work tools. Advanced training classes teach people how to optimize and do preventive repair.

The availability of technical help has a big effect on the ability to keep the stained glass cutting machine working. With remote testing capabilities, problems can be fixed quickly without having to wait for someone to come to the spot. The amount and speed of supply of available spare parts affect the amount of time that tools can be used. Comprehensive service agreements let you know how much support will cost and make sure that help will get to you quickly.

Cost Analysis and Return on Investment

The total cost of ownership includes more than just the price of the item itself; it also includes the costs of installing it, teaching people to use it, maintaining it, and operating it. The continued operating economics are affected by energy use, the cost of consumables, and savings from lessening the need for workers. Increased output and less trash often make the cost of new tools worth it.

You can buy it right away, lease it, or join a rent-to-own scheme. If a business wants to keep its money safe, it might make more sense to lease instead of buying. The best ways to finance a business depend on where it is located and what type of company it is, because taxes are different in each case.

Both direct savings and productivity gains should be taken into account when calculating the payback time. The cash gains are caused by the following: needing less work, making better use of materials, and improving the quality of products. Better skills may help you enter new markets, which can help your business make more money.

Conclusion

It is important to think about quality standards, production needs, and long-term business goals when choosing glass cutting tools. New systems can do things that were not possible before in terms of accuracy, automation, and moving materials around. Knowing about important aspects, ways to integrate, and support needs helps people make smart choices that get the most out of their money. The glass fabrication business is moving toward more automation and accuracy. Because of this, choosing the right tools is very important for staying ahead of the competition. Getting help from professionals with a lot of experience in manufacturing makes sure that your system is set up correctly. Support services that help with everything also make sure that your investment stays valuable in the long run.

Partner with HUASHIL for Advanced Glass Cutting Solutions

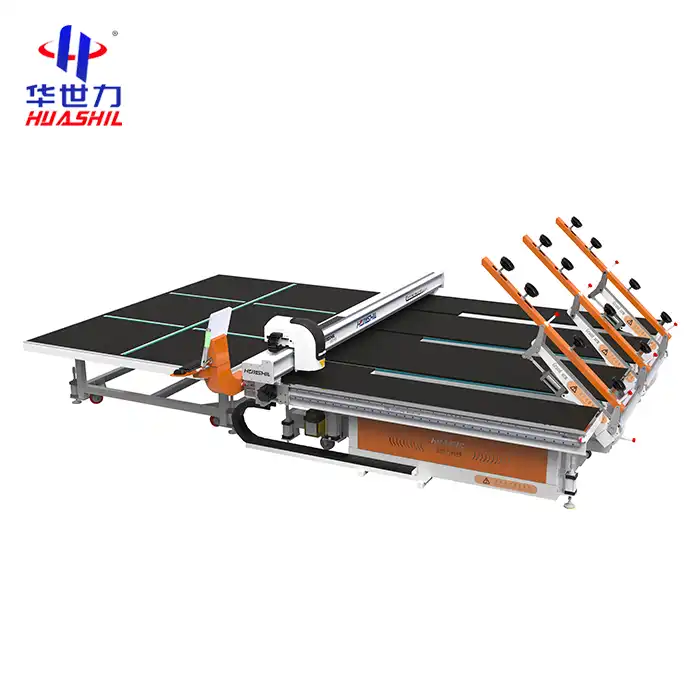

Shandong Huashil Automation Technology is a leader in new glass machines. Their state-of-the-art solutions change the way glass is used in buildings, art, and industry. Our full line of automatic glass cutting systems uses precise engineering and strong construction to make sure they work well even in tough production settings.

As a well-known maker of stained glass cutting machines, HUASHIL combines decades of experience with knowledge of the difficulties involved in making glass. From small workshop systems to fully automatic production lines, our engineering team comes up with custom solutions for unique production needs. Servo-controlled positioning, smart cutting optimization, and smooth merging with current production processes are all examples of advanced technology capabilities.

Quality assurance is still very important in our manufacturing process, and before shipping, each system is put through very hard tests. Broad insurance coverage and quick technical support help keep production delays to a minimum and equipment uptime to a maximum. No matter where in the world the placement is, our global service network can help you as a local team, with the ability to quickly supply a wide range of spare parts.

Whether you're expanding existing operations or establishing new production capabilities, HUASHIL delivers the technology, support, and expertise needed for success. Our commitment to innovation drives continuous product development, ensuring our customers benefit from the latest advances in glass cutting automation. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and discover how our advanced glass cutting solutions can transform your production capabilities.

References

1. Glass Manufacturing Industry Council. "Automation Trends in Glass Fabrication: 2025 Industry Report." Glass Technology Quarterly, 2024.

2. International Association of Glass Processors. "Precision Cutting Technologies for Architectural Glass Applications." Advanced Glass Processing Journal, Vol. 47, 2024.

3. Chen, L., Zhang, M., and Wang, H. "Computer-Controlled Glass Cutting Systems: Performance Analysis and Optimization Strategies." Industrial Automation Review, 2024.

4. European Glass Technology Institute. "Quality Standards and Testing Protocols for Automated Glass Cutting Equipment." Glass Engineering Standards, 3rd Edition, 2024.

5. Smith, R.J. and Thompson, K.L. "Economic Analysis of Glass Processing Automation: Cost-Benefit Studies from Manufacturing Facilities." Manufacturing Economics Quarterly, 2024.

6. Asian Glass Machinery Manufacturers Association. "Technical Specifications and Performance Benchmarks for Industrial Glass Cutting Systems." Machinery Standards Publication, 2024.