In the world of glass manufacturing and processing, automatic glass cutting lines have revolutionized the industry. These sophisticated machines have significantly improved efficiency, precision, and productivity in glass cutting operations. Whether you're new to the glass industry or looking to upgrade your existing equipment, this comprehensive guide will walk you through the essentials of automatic glass cutting lines. Automatic glass cutting lines are advanced systems designed to streamline the process of cutting large sheets of glass into smaller, precise pieces. These lines integrate cutting-edge technology with robust machinery to handle various types of glass, including float glass, low-E glass, and laminated glass. The automation aspect reduces human error, increases output, and ensures consistent quality across production runs. Let's delve into the key aspects of operating these machines, essential safety measures, and common mistakes to avoid.

How to operate an automatic glass cutting line step by step?

Operating an automatic glass cutting line requires a combination of technical knowledge and practical skills. Here's a detailed breakdown of the process:

Pre-operation checks

Before starting the machine, conduct a thorough inspection of all components. This includes checking:

- The cutting head for any signs of wear or damage

- The conveyor belt for proper tension and alignment

- The control panel for any error messages or warnings

- The air pressure system for leaks or irregularities

- The cutting oil reservoir for adequate levels

Loading the glass

Proper loading is crucial for optimal performance:

- Ensure the loading area is clean and free from debris

- Use the appropriate lifting equipment to place the glass sheet onto the loading table

- Align the glass carefully with the machine's reference points

- If your line has an automatic loading system, program the desired sheet size and quantity

Programming the cut

Modern automatic glass cutting lines, such as customized automatic glass cutting line, often feature advanced software for cut optimization:

- Input the required dimensions and quantities into the system

- Allow the software to calculate the most efficient cutting pattern

- Review the proposed pattern and make any necessary adjustments

- Confirm the program and send it to the machine

Initiating the cutting process

Once everything is set up:

- Start the machine using the control panel

- Monitor the initial cuts to ensure accuracy

- Be prepared to make minor adjustments if needed

Monitoring and quality control

During operation:

- Keep an eye on the cutting process for any irregularities

- Regularly check the quality of the cuts

- Listen for any unusual noises that might indicate a problem

- Monitor the cutting oil levels and replenish as necessary

Unloading and sorting

As the machine completes the cuts:

- Allow the cut pieces to move to the unloading area

- If your line has an automatic sorting system, ensure it's functioning correctly

- For manual sorting, carefully remove the cut pieces and stack them appropriately

Post-operation procedures

After completing the cutting process:

- Clean the machine thoroughly, removing any glass chips or debris

- Perform any necessary maintenance as per the manufacturer's guidelines

- Document the day's production and any issues encountered

By following these steps, operators can ensure smooth and efficient operation of their automatic glass cutting line. However, it's important to note that specific procedures may vary depending on the make and model of your equipment. Always refer to your machine's manual for detailed instructions.

Essential safety measures when using an automatic glass cutter

Safety should always be the top priority when working with automatic glass cutting equipment. These machines, while highly efficient, can pose significant risks if not operated properly. Here are some essential safety measures to implement:

Personal Protective Equipment (PPE)

Proper PPE is non-negotiable:

- Safety glasses or goggles to protect eyes from glass chips and dust

- Cut-resistant gloves when handling glass

- Steel-toed boots to protect feet from falling glass pieces

- Hearing protection if noise levels exceed safe limits

Machine guarding

Ensure all safety guards are in place:

- Never remove or bypass safety guards

- Regularly inspect guards for damage or wear

- Report any missing or damaged guards immediately

Emergency stop procedures

All operators of the automatic glass cutting line should be familiar with emergency stop procedures:

- Locate all emergency stop buttons before operating the machine

- Conduct regular drills to ensure quick response in emergencies

- Keep emergency stop buttons easily accessible and free from obstruction

Proper training

Only trained personnel should operate the equipment:

- Provide comprehensive training on machine operation and safety procedures

- Conduct regular refresher courses

- Ensure operators are familiar with the specific model they're using

Maintenance and inspection

Regular maintenance is crucial for safe operation:

- Follow the manufacturer's recommended maintenance schedule

- Conduct daily pre-operation checks

- Address any issues promptly before they become safety hazards

Clean work environment

Maintain a clean and organized workspace:

- Regularly clean the machine and surrounding area

- Properly dispose of glass waste and debris

- Keep walkways clear and free from tripping hazards

Electrical safety

Be mindful of electrical hazards:

- Ensure all electrical connections are properly insulated

- Never operate the machine with wet hands or in wet conditions

- Only qualified personnel should perform electrical maintenance

Proper material handling

Use correct techniques when handling glass:

- Use appropriate lifting equipment for large sheets

- Never attempt to catch falling glass

- Be aware of sharp edges when handling cut pieces

Lockout/Tagout procedures

Implement strict lockout/tagout procedures:

- Always disconnect power sources before performing maintenance

- Use lockout devices to prevent accidental startup

- Clearly communicate when machines are under maintenance

Emergency response plan

Have a well-defined emergency response plan:

- Post emergency contact numbers prominently

- Ensure first aid kits are readily available and fully stocked

- Train employees in basic first aid and emergency procedures

By implementing these safety measures, you can significantly reduce the risk of accidents and injuries when operating an automatic glass cutting line. Remember, safety is an ongoing process that requires constant vigilance and commitment from all team members.

Common mistakes to avoid with automatic glass cutting machines

Even with advanced technology, errors can occur in the operation of automatic glass cutting lines. Being aware of common mistakes can help operators avoid costly errors and maintain efficient production. Here are some pitfalls to watch out for:

Neglecting regular maintenance

One of the most critical mistakes is overlooking routine maintenance:

- Failing to clean the machine regularly can lead to buildup of glass dust and debris

- Neglecting to lubricate moving parts can cause premature wear and tear

- Ignoring minor issues can lead to major breakdowns and production delays

Improper loading techniques

Incorrect loading of the customized automatic glass cutting line can lead to cutting inaccuracies and potential damage:

- Failing to align glass sheets properly on the cutting table

- Overloading the machine beyond its specified capacity

- Not accounting for glass thickness variations in the loading process

Incorrect software programming

Errors in programming can result in wasted material and time:

- Inputting incorrect dimensions or quantities

- Failing to optimize cutting patterns for maximum glass utilization

- Not accounting for specific customer requirements in the cutting program

Ignoring calibration requirements

Regular calibration is essential for maintaining cutting accuracy:

- Neglecting to calibrate the cutting head can lead to imprecise cuts

- Failing to adjust for wear on cutting wheels can affect cut quality

- Not accounting for environmental factors like temperature in calibration

Overriding safety features

Bypassing safety mechanisms is a dangerous and illegal practice:

- Disabling emergency stop buttons or safety guards

- Ignoring warning signals or error messages

- Operating the machine without proper safety equipment

Inadequate operator training

Insufficient training can lead to numerous operational errors:

- Lack of understanding of the machine's full capabilities

- Inability to troubleshoot minor issues

- Failure to follow proper operating procedures

Incorrect cutting speed and pressure

Using inappropriate cutting parameters can affect quality and efficiency:

- Setting cutting speed too high can lead to incomplete cuts or breakage

- Insufficient cutting pressure can result in scoring rather than clean cuts

- Failing to adjust parameters for different glass types and thicknesses

Poor quality control practices

Neglecting quality checks can result in substandard products:

- Not regularly inspecting cut pieces for accuracy and quality

- Failing to adjust the machine when defects are detected

- Overlooking the importance of consistent edge quality

Improper handling of cut glass

Mishandling cut pieces can lead to damage and waste:

- Stacking cut pieces incorrectly, leading to scratches or breaks

- Not using appropriate handling equipment for large or heavy pieces

- Failing to properly package cut glass for transport or storage

Neglecting environmental factors

Failing to account for environmental conditions can affect cutting precision:

- Not considering the effects of temperature fluctuations on glass expansion

- Ignoring humidity levels that can affect the cutting process

- Failing to maintain a clean and dust-free environment around the cutting line

By being aware of these common mistakes and taking proactive steps to avoid them, operators can ensure optimal performance of their automatic glass cutting line. Regular training, strict adherence to operating procedures, and a commitment to quality control are key to maximizing the benefits of this advanced technology.

Conclusion

Automatic glass cutting lines represent a significant advancement in glass processing technology. They offer unparalleled precision, efficiency, and productivity when operated correctly and safely. By understanding the proper operation procedures, implementing rigorous safety measures, and avoiding common mistakes, glass manufacturers can fully leverage the potential of these sophisticated machines.

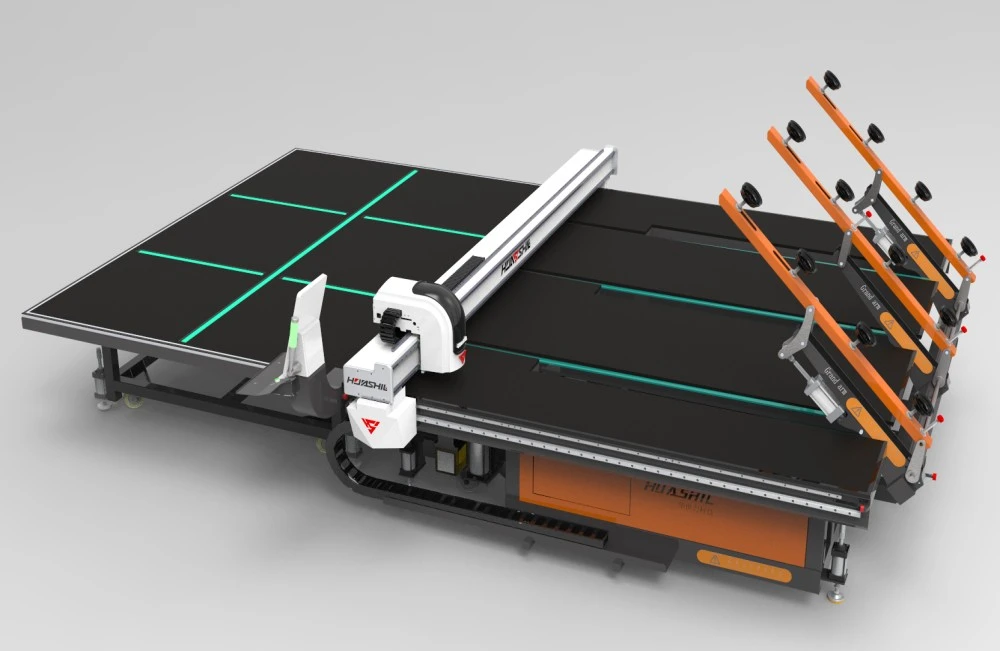

Are you looking to upgrade your glass cutting capabilities? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge automatic glass cutting solutions tailored to your specific needs. With years of experience in R&D, manufacturing, and sales of automated equipment, we offer advanced technology, stable quality, and excellent service that has satisfied customers worldwide. Don't let outdated equipment hold back your production - contact us today at salescathy@sdhuashil.com to discover how our automatic glass cutting lines can transform your operations and drive your business forward.

References

1. Johnson, M. (2022). Advanced Glass Cutting Technologies: A Comprehensive Guide. Glass Industry Journal, 45(3), 78-92.

2. Smith, A. & Brown, L. (2021). Safety Protocols in Automated Glass Manufacturing. Industrial Safety Review, 18(2), 112-125.

3. Zhang, Y. et al. (2023). Optimization Techniques for Automatic Glass Cutting Lines. Journal of Manufacturing Processes, 76, 234-249.

4. Anderson, K. (2020). Common Pitfalls in Glass Cutting Automation: Lessons from the Industry. Glass Technology, 61(4), 156-170.