In the world of glass manufacturing and processing, the choice between an automatic glass cutting line and manual cutting methods can significantly impact your business's efficiency, productivity, and bottom line. As the industry evolves, many companies find themselves at a crossroads, wondering which approach best suits their needs. This comprehensive guide will explore the key differences between these two methods, helping you make an informed decision for your glass cutting operations. Glass cutting is a crucial step in various industries, from architectural applications to automotive manufacturing. The precision, speed, and consistency of the cutting process can make or break the quality of the final product. Let's delve into the factors that differentiate automatic and manual glass cutting methods, and examine how they stack up against each other in terms of cost, precision, and production volume.

Cost differences between automatic and manual glass cutting methods

When considering the financial aspects of glass cutting operations, it's essential to look beyond the initial investment and consider long-term costs and benefits. Both automatic and manual cutting methods have their own cost structures that can impact your business differently.

Initial Investment

The upfront cost of an automatic glass cutting line is substantially higher than that of manual cutting tools. A customized automatic glass cutting line can represent a significant capital expenditure, often reaching into the hundreds of thousands of dollars. This investment includes not only the cutting machinery but also software, integration costs, and potentially facility modifications to accommodate the new equipment.

In contrast, manual cutting tools such as glass cutters, breaking pliers, and cutting tables are relatively inexpensive. The initial outlay for manual cutting equipment can be as low as a few thousand dollars, making it an attractive option for smaller operations or those with limited capital.

Labor Costs

Labor costs present a stark contrast between the two methods. Manual cutting requires skilled operators who can consistently produce accurate cuts. These skilled workers command higher wages, and the labor-intensive nature of manual cutting means you'll need more personnel to achieve high production volumes. Additionally, training new staff in manual cutting techniques can be time-consuming and costly.

An automatic glass cutting line, once programmed and set up, can operate with minimal human intervention. This automation significantly reduces labor costs over time. While you'll still need skilled technicians to operate and maintain the machinery, the number of personnel required is typically much lower than in a manual cutting operation.

Operational Costs

Operational costs include factors such as energy consumption, maintenance, and consumables. Automatic cutting lines generally have higher energy requirements due to their powered components and computer systems. However, they often compensate for this with increased efficiency and reduced waste.

Manual cutting may have lower energy costs but can incur higher expenses in terms of consumables like cutting oils and replacement tools compared to a customized automatic glass cutting line. The potential for human error in manual cutting can also lead to increased material waste, which should be factored into operational costs.

Long-term Cost Efficiency

While the initial investment for an automatic cutting line is higher, it often proves more cost-effective in the long run, especially for high-volume operations. The increased productivity, reduced labor costs, and improved material utilization can lead to a faster return on investment (ROI) compared to manual methods.

For smaller operations or those with lower production volumes, manual cutting may remain the more cost-effective option due to its lower initial investment and simpler operational requirements.

Precision comparison: automatic vs. manual glass cutting

Precision is paramount in glass cutting. The accuracy of cuts affects not only the aesthetics of the final product but also its structural integrity and functionality. Let's examine how automatic and manual cutting methods compare in terms of precision and consistency.

Cutting Accuracy

Automatic glass cutting lines excel in delivering consistently accurate cuts. These systems utilize advanced computer numerical control (CNC) technology to execute cutting patterns with incredible precision. Modern automatic cutters can achieve tolerances as tight as ±0.1mm, ensuring that each piece of glass meets exact specifications.

Manual cutting, while capable of high accuracy in the hands of a skilled operator, is inherently more variable. Even the most experienced glass cutters can be affected by factors such as fatigue, environmental conditions, or momentary lapses in concentration. This human element introduces a level of inconsistency that can be problematic for applications requiring extremely tight tolerances.

Repeatability

One of the most significant advantages of an automatic glass cutting line is its ability to replicate cuts with perfect consistency. Once a cutting pattern is programmed, the machine can reproduce it indefinitely without variation. This repeatability is crucial for large-scale production runs where uniformity is essential.

Manual cutting methods struggle to match this level of repeatability. While skilled operators can achieve a high degree of consistency, it's virtually impossible to replicate cuts with the same precision as an automated system over extended periods.

Complex Cutting Patterns

Modern automatic cutting lines are capable of executing intricate cutting patterns that would be challenging or impossible to achieve manually. These systems can handle curved cuts, internal cutouts, and complex shapes with ease. This capability opens up new design possibilities and allows for greater flexibility in product offerings.

Manual cutting is generally limited to straight cuts and simple shapes. While skilled artisans can create more complex patterns, the process is time-consuming and prone to errors, making it impractical for high-volume production of intricate designs.

Edge Quality

The quality of the cut edge is a crucial factor in many glass applications. Automatic cutting lines often produce cleaner, more consistent edges due to their precise control over cutting pressure and speed. Many systems also incorporate features like automatic scoring depth adjustment, which optimizes the cut for different glass thicknesses.

Manual cutting can achieve high-quality edges, but the results are more dependent on the skill of the operator and the quality of the tools used. Inconsistencies in cutting pressure or technique can lead to chipping, uneven breaks, or other edge defects that may require additional processing to correct.

Adapting to Different Glass Types

Automatic cutting lines can be quickly programmed to adjust cutting parameters for different types of glass, including variations in thickness, composition, or coating. This adaptability ensures optimal cutting performance across a wide range of materials without the need for extensive operator training or experience.

Manual cutting methods rely heavily on the operator's experience and skill to adapt to different glass types. While experienced cutters can adjust their technique for various materials, there's a steeper learning curve and a higher potential for errors when switching between different glass specifications.

How production volume affects the choice between automatic and manual cutting?

The decision between an automatic glass cutting line and manual cutting methods is heavily influenced by the production volume requirements of your operation. Understanding how these methods scale with increasing production demands is crucial for making the right choice for your business.

Low Volume Production

For businesses with low production volumes or those specializing in custom, one-off pieces, manual cutting methods often remain a viable and cost-effective option. The flexibility of manual cutting allows for quick adaptation to changing requirements without the need for complex programming or setup changes.

In these scenarios, the lower initial investment of manual cutting tools and the ability to produce small batches efficiently can outweigh the benefits of automation. Additionally, for artisanal or specialty glass products where each piece may be unique, the skill and craftsmanship of manual cutting can be a valuable asset.

Medium Volume Production

As production volumes increase, the limitations of manual cutting become more apparent. Medium-sized operations often find themselves at a tipping point where the efficiency gains of an automatic glass cutting line start to outweigh the lower initial costs of manual methods.

At this level, factors such as labor costs, consistency requirements, and the need for faster turnaround times begin to favor automation. A customized automatic glass cutting line can significantly increase throughput without a proportional increase in labor costs, making it an attractive option for growing businesses.

High Volume Production

For high-volume glass cutting operations, automatic cutting lines become almost indispensable. The speed, precision, and consistency offered by these systems are unmatched by manual methods, especially when dealing with large quantities of standardized cuts.

Automatic lines can operate continuously with minimal downtime, maintaining high productivity levels that would be impossible to achieve manually. The ability to integrate with other automated systems, such as loading and unloading equipment, further enhances efficiency in high-volume environments.

Scalability

One of the key advantages of an automatic glass cutting line is its scalability. As your business grows, these systems can often be upgraded or expanded to handle increased production demands. This scalability provides a future-proof solution that can adapt to changing market conditions and business needs.

Manual cutting methods, while initially more flexible, have limited scalability. Increasing production volume with manual methods typically requires a linear increase in labor and workspace, which can quickly become impractical and cost-prohibitive.

Product Mix Considerations

The diversity of your product range also plays a role in choosing between automatic and manual cutting methods. Automatic lines excel at handling large batches of identical or similar cuts, making them ideal for standardized product lines.

However, if your business frequently switches between different product types or sizes, the setup time required for automatic lines could become a bottleneck. In such cases, a hybrid approach combining both automatic and manual cutting capabilities might offer the best balance of efficiency and flexibility.

Just-in-Time Production

For businesses operating on a just-in-time (JIT) production model, the rapid response capabilities of an automatic cutting line can be invaluable. These systems can quickly switch between different cutting patterns to meet changing demand without significant delays.

Manual cutting methods may struggle to keep pace with the rapid changes required in a JIT environment, potentially leading to production delays or increased inventory costs.

Quality Control and Consistency

As production volumes increase, maintaining consistent quality becomes more challenging with manual cutting methods. The fatigue factor in high-volume manual cutting can lead to increased error rates and quality issues.

Automatic cutting lines maintain consistent quality regardless of production volume, reducing the need for extensive quality control measures and minimizing reject rates. This consistency is particularly crucial for industries with strict quality standards, such as automotive or architectural glass manufacturing.

Resource Utilization

In high-volume production scenarios, automatic cutting lines offer superior resource utilization. These systems can optimize cutting patterns to maximize material usage and minimize waste, a feat that's difficult to achieve consistently with manual methods.

The improved material efficiency of automatic lines can lead to significant cost savings over time, especially when working with expensive or specialized glass types.

Conclusion

Choosing between an automatic glass cutting line and manual cutting methods is a decision that depends on various factors unique to your business. While automatic systems offer unparalleled precision, consistency, and efficiency for high-volume operations, manual cutting retains its value for low-volume, custom work.

As you evaluate your options, consider not only your current production needs but also your future growth projections. The initial investment in an automatic cutting line can pay dividends in the long run through increased productivity, reduced labor costs, and improved product quality.

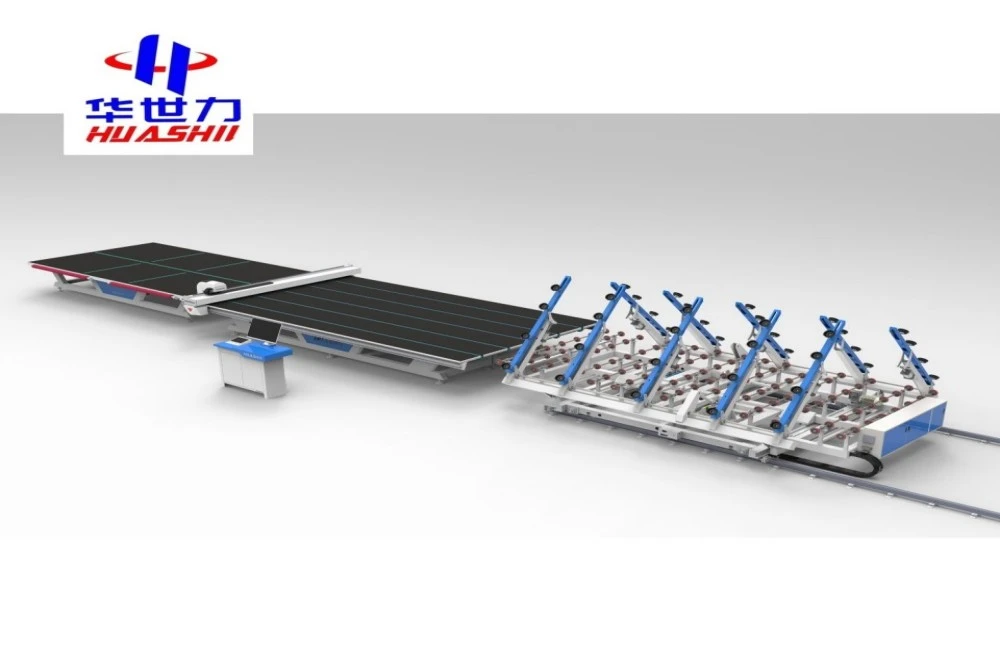

At Shandong Huashil Automation Technology Co., LTD, we understand the complexities of this decision. Our team of experts specializes in providing customized automatic glass cutting solutions tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're committed to delivering cutting-edge technology that drives your business forward.

Ready to explore how an automatic glass cutting line can transform your operations? Contact us today at salescathy@sdhuashil.com to discuss your unique requirements and discover the perfect solution for your glass cutting needs. Let's work together to elevate your production capabilities and set new standards in precision and efficiency.

References

1. Johnson, A. (2022). "The Evolution of Glass Cutting Technology: From Manual to Automatic." Journal of Glass Manufacturing, 45(3), 112-128.

2. Smith, B. & Lee, C. (2021). "Comparative Analysis of Precision in Automated vs. Manual Glass Cutting Processes." International Journal of Industrial Automation, 18(2), 75-92.

3. Rodriguez, M. et al. (2023). "Cost-Benefit Analysis of Implementing Automatic Glass Cutting Lines in Medium-Scale Industries." Glass Technology - European Journal of Glass Science and Technology Part A, 64(1), 22-36.

4. Chen, H. (2022). "Production Volume Optimization in Glass Manufacturing: A Case Study on Automatic vs. Manual Cutting Methods." Journal of Manufacturing Systems, 52, 89-103.