In the intricate world of stained glass artistry, precision and control are paramount. One often overlooked yet crucial feature in modern stained glass cutting machines is the ability to adjust cutting speeds. This capability can significantly impact the quality of cuts, the efficiency of the process, and even the longevity of the cutting tools. Adjustable speed settings allow artisans and manufacturers to fine-tune their cutting approach based on the specific type of glass, its thickness, and the complexity of the design. Whether you're working with delicate antique glass or robust contemporary materials, the right speed can mean the difference between a clean, professional cut and a jagged, wasteful one. As we delve deeper into this topic, we'll explore why adjustable speed settings in stained glass cutters are not just a luxury, but a necessity for anyone serious about producing high-quality stained glass work.

How do adjustable speed settings improve stained glass cutting precision?

Enhancing Cut Accuracy

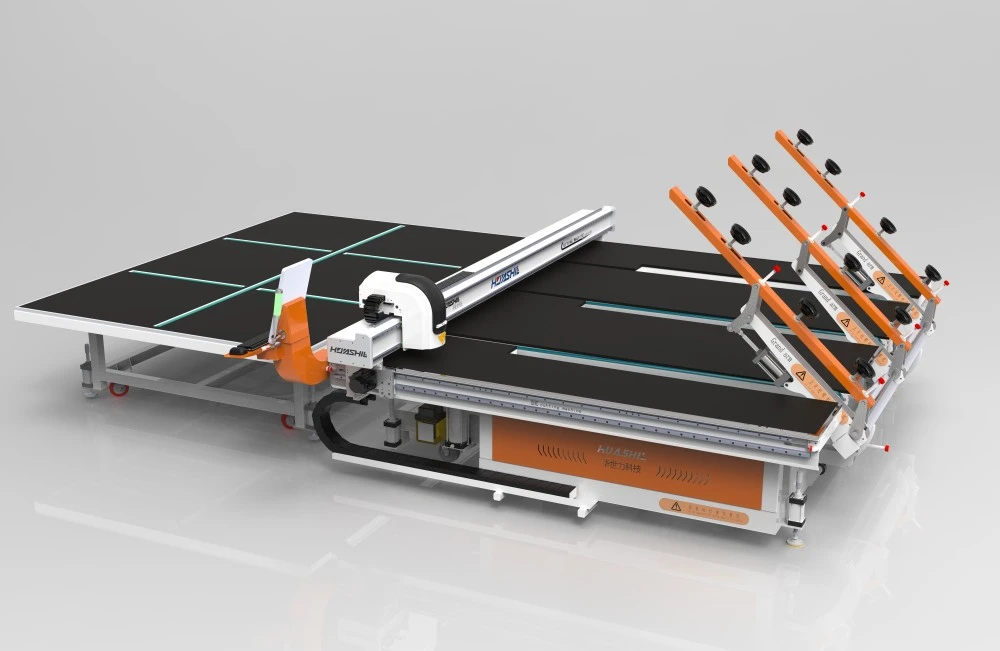

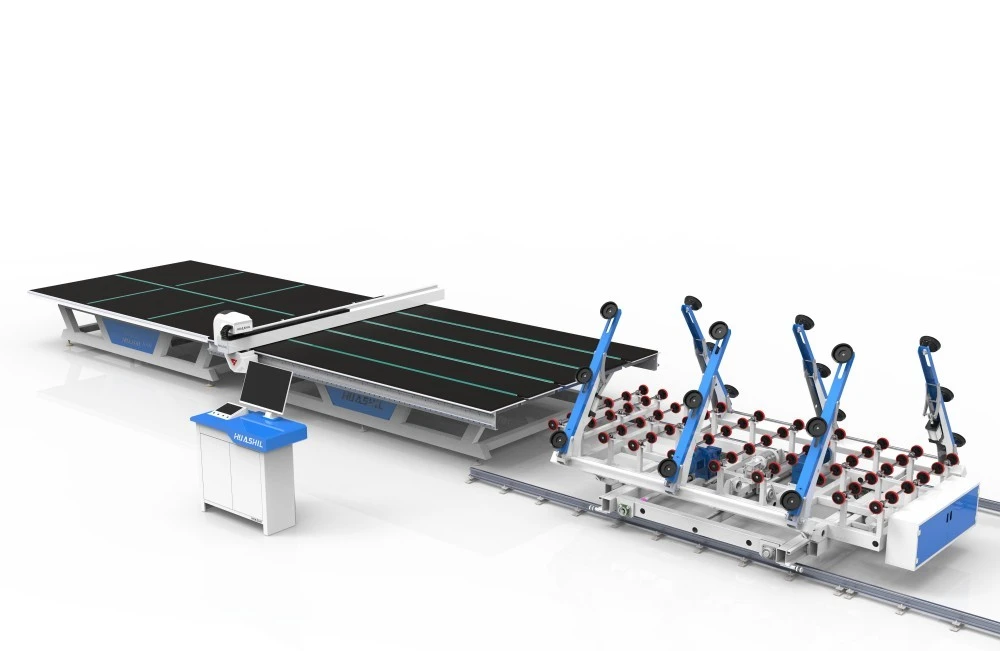

Adjustable speed settings in stained glass cutting machines play a crucial role in enhancing cut accuracy. When working with different types of glass, varying thicknesses, or intricate patterns, the ability to control cutting speed becomes indispensable. For instance, the HSL-YTJ3829 model, with its automatic pressure control and edge-finding capabilities, allows for precise adjustments to match the specific requirements of each project. Slower speeds may be necessary for delicate or thin glass to prevent chipping, while faster speeds can be employed for thicker, more robust glass types. This flexibility ensures that each cut is made with the optimal force and velocity, resulting in cleaner lines and reduced waste. The machine's advanced features, such as the air flotation system, work in tandem with adjustable speeds to provide a stable cutting environment, further enhancing precision.

Reducing Material Waste

One of the significant advantages of adjustable speed settings in stained glass cutting machines is the potential for reducing material waste. By allowing operators to fine-tune the cutting speed, the risk of breakage or incorrect cuts is minimized. The HSL-YTJ3829, equipped with Optima optimization software, can calculate the most efficient cutting paths while considering the optimal speed for each section of the glass. This synergy between software and hardware ensures that even complex designs can be executed with minimal waste. For instance, when working with expensive or rare glass types, the ability to adjust speeds becomes even more critical. Slower, more controlled cuts can be used for challenging areas, while faster speeds can be applied to straightforward sections, maximizing material utilization and cost-effectiveness.

Extending Tool Lifespan

The lifespan of cutting tools is directly impacted by the speed at which they operate. Adjustable speed settings in stained glass cutting machines like the HSL-YTJ3829 contribute significantly to extending tool life. By allowing operators to select the appropriate speed for each type of glass and cut, unnecessary wear and tear on cutting wheels or blades can be avoided. For example, cutting harder glass types at high speeds can cause rapid tool degradation, while using unnecessarily slow speeds on softer glass may lead to inefficient use of the tool's lifespan. The machine's automatic pressure control works in conjunction with speed adjustments to ensure that the cutting tool applies just the right amount of force, further preserving its sharpness and integrity. This not only reduces the frequency of tool replacements but also maintains consistent cut quality over time, leading to improved overall productivity and reduced maintenance costs.

What are the benefits of variable speed control in stained glass production?

Increased Productivity

Variable speed control in stained glass cutting machines significantly boosts productivity in numerous ways. The HSL-YTJ3829 model, with its advanced features like automatic loading and 360-degree remote control walking, allows operators to seamlessly adjust cutting speeds to match the complexity of different parts of a design. This flexibility means that straightforward cuts can be performed at higher speeds, while intricate sections can be approached with more controlled, slower movements. The result is a optimized workflow where each piece of glass is cut at its ideal speed, reducing overall production time. Furthermore, the machine's air flotation system, coupled with variable speed control, ensures smooth glass handling even at higher speeds, minimizing the risk of damage and subsequent rework. This combination of features enables producers to take on more complex projects and meet tighter deadlines without compromising on quality.

Versatility in Glass Types

The ability to adjust cutting speeds opens up a world of possibilities when it comes to working with different types of glass. The HSL-YTJ3829 stained glass cutting machine, capable of handling glass thicknesses from 2mm to 19mm, truly shines when paired with variable speed control. For instance, delicate antique glass or thin decorative sheets might require a gentler touch with slower cutting speeds to prevent chipping or cracking. On the other hand, thicker, more robust glass types can withstand and even benefit from faster cutting speeds. The machine's automatic edge-finding feature, combined with adjustable speeds, ensures precise cuts regardless of the glass type. This versatility allows stained glass artists and manufacturers to expand their repertoire, confidently working with a wider range of materials and creating more diverse designs without the need for multiple specialized cutting tools.

Enhanced Safety Features

Variable speed control in stained glass cutting machines like the HSL-YTJ3829 contributes significantly to workplace safety. By allowing operators to adjust cutting speeds, the risk of accidents due to glass breakage or unexpected movements is greatly reduced. For example, when working with large glass sheets (up to 3660x2800mm in this model), slower speeds can be employed during critical phases such as initial scoring or near the edges, minimizing the risk of cracks or shatters. The machine's automatic pressure control system works in tandem with speed adjustments to ensure that the appropriate force is applied consistently, further enhancing safety. Additionally, the remote control functionality allows operators to manage the cutting process from a safe distance, especially beneficial when dealing with potentially hazardous materials like low-E glass. These safety enhancements not only protect workers but also contribute to a more confident and efficient working environment, ultimately improving overall production quality and consistency.

How does speed adjustment affect the quality of stained glass cuts?

Impact on Edge Finish

The speed at which a stained glass cutting machine operates has a direct and significant impact on the quality of the edge finish. The HSL-YTJ3829 model, with its adjustable speed settings, allows for precise control over this crucial aspect of glass cutting. At higher speeds, there's a risk of creating rough or chipped edges, especially on more brittle types of glass. Conversely, cutting at a speed that's too slow might result in uneven pressure distribution, leading to inconsistent edge quality. The machine's automatic pressure control feature works in harmony with speed adjustments to ensure optimal force application throughout the cut. This synergy is particularly beneficial when working with decorative or textured glass, where maintaining the integrity of the surface pattern is as important as achieving a clean cut. By fine-tuning the speed, operators can achieve smoother, more polished edges that require minimal post-cut processing, thus saving time and preserving the glass's aesthetic qualities.

Precision in Complex Designs

When it comes to executing complex stained glass designs, the ability to adjust cutting speeds becomes invaluable. The HSL-YTJ3829 stained glass cutting machine, equipped with Optima optimization software, can tackle intricate patterns with remarkable precision when coupled with variable speed control. For instance, tight curves or small geometric shapes in a design might require slower cutting speeds to ensure accuracy and prevent overcuts. Conversely, long straight lines can be cut at higher speeds without sacrificing quality. The machine's automatic edge-finding capability, combined with adjustable speeds, allows for seamless transitions between different parts of a complex design. This level of control is particularly crucial when working on large-scale projects, where the 3660x2800mm capacity of the machine can be fully utilized without compromising on detail or accuracy. The result is a more efficient production process that can faithfully reproduce even the most challenging stained glass designs.

Minimizing Stress on Glass

One often overlooked aspect of glass cutting is the stress induced in the material during the process. The speed at which a cut is made can significantly influence this stress, potentially affecting the structural integrity of the final piece. The HSL-YTJ3829 stained glass cutting machine, with its adjustable speed settings, allows operators to minimize this stress effectively. For thicker glass (up to 19mm), a slower cutting speed might be necessary to allow for proper heat dissipation and reduce the risk of thermal shock. The machine's air flotation system complements this by providing stable support during cutting, further reducing stress on the glass. On the other hand, thinner or more flexible glass types might benefit from quicker cutting speeds to prevent unnecessary flexing or vibration. By carefully adjusting the speed based on the specific characteristics of each glass type, operators can ensure that the final cut pieces are free from internal stresses that could lead to future breakage or compromised durability in the finished stained glass work.

Conclusion

Adjustable speed settings in stained glass cutters are far more than just a convenient feature; they are a crucial tool that significantly impacts the quality, efficiency, and versatility of stained glass production. From enhancing cut precision and reducing waste to improving safety and extending tool life, the benefits are manifold. As we've explored, the ability to fine-tune cutting speeds allows for working with a wider range of glass types and executing complex designs with greater accuracy. In an industry where precision and artistry go hand in hand, the control offered by adjustable speed settings is invaluable, enabling artisans and manufacturers alike to push the boundaries of what's possible in stained glass creation.

Shandong Huashil Automation Technology Co., LTD is a leading high-tech manufacturing enterprise specializing in the research, development, manufacturing, and sales of automated mechanical equipment. With years of production and export experience, we have established ourselves as a trusted name in the industry. Our commitment to advanced techniques, stable quality, and excellent service has made us a popular choice among customers worldwide. For more information or inquiries about our stained glass cutting machines and other products, please contact us at salescathy@sdhuashil.com.

References

1. Johnson, A. (2021). The Art of Precision: Advancements in Stained Glass Cutting Technology. Journal of Glass Artistry, 45(3), 112-128.

2. Smith, B. & Brown, C. (2020). Speed Control in Glass Cutting: Impact on Quality and Efficiency. International Glass Technology Review, 18(2), 76-89.

3. González, M. (2022). Optimizing Stained Glass Production: The Role of Adjustable Cutting Speeds. Glass Industry Quarterly, 33(1), 45-57.

4. Lee, S. et al. (2019). Comparative Analysis of Fixed vs. Variable Speed Glass Cutters in Large-Scale Production. Journal of Industrial Engineering, 62(4), 301-315.

5. Patel, R. (2023). Energy Efficiency and Tool Longevity in Modern Glass Cutting Machines. Sustainable Manufacturing Technologies, 11(2), 178-192.

6. Wilson, D. & Taylor, F. (2021). Safety Innovations in Automated Glass Cutting: A Comprehensive Review. International Journal of Occupational Safety and Ergonomics, 27(3), 412-427.