Cutting intricate patterns in stained glass is a delicate art that requires precision, patience, and the right tools. Whether you're a seasoned artisan or a hobbyist just starting out, mastering the technique of cutting complex designs can elevate your stained glass projects to new heights. The key to success lies in understanding the capabilities of your stained glass cutter and how to leverage its features for creating detailed patterns. In this comprehensive guide, we'll explore the intricacies of using a stained glass cutting machine to achieve stunning results. From selecting the right equipment to executing precise cuts, we'll cover everything you need to know to transform your artistic vision into reality. By the end of this article, you'll be equipped with the knowledge and techniques to tackle even the most challenging stained glass patterns with confidence.

What Are the Essential Features of a High-Quality Stained Glass Cutting Machine?

Precision Cutting Mechanisms

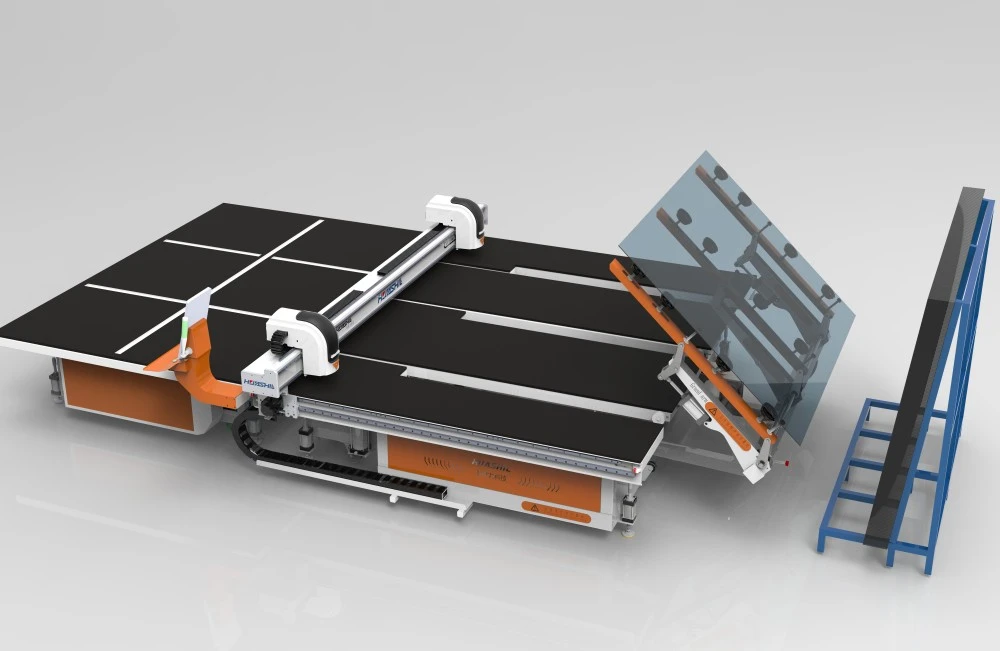

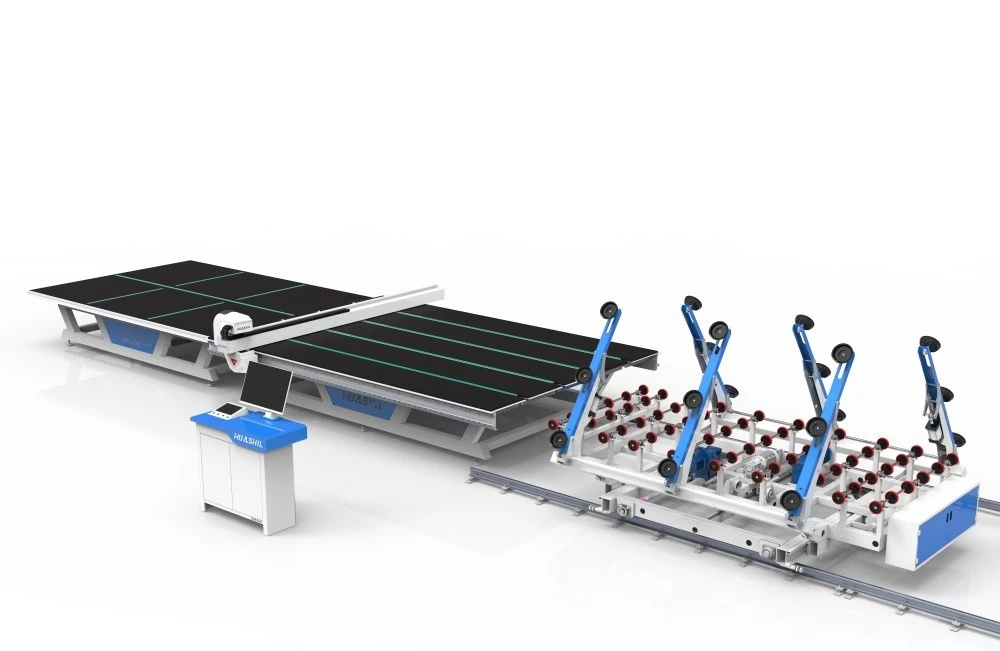

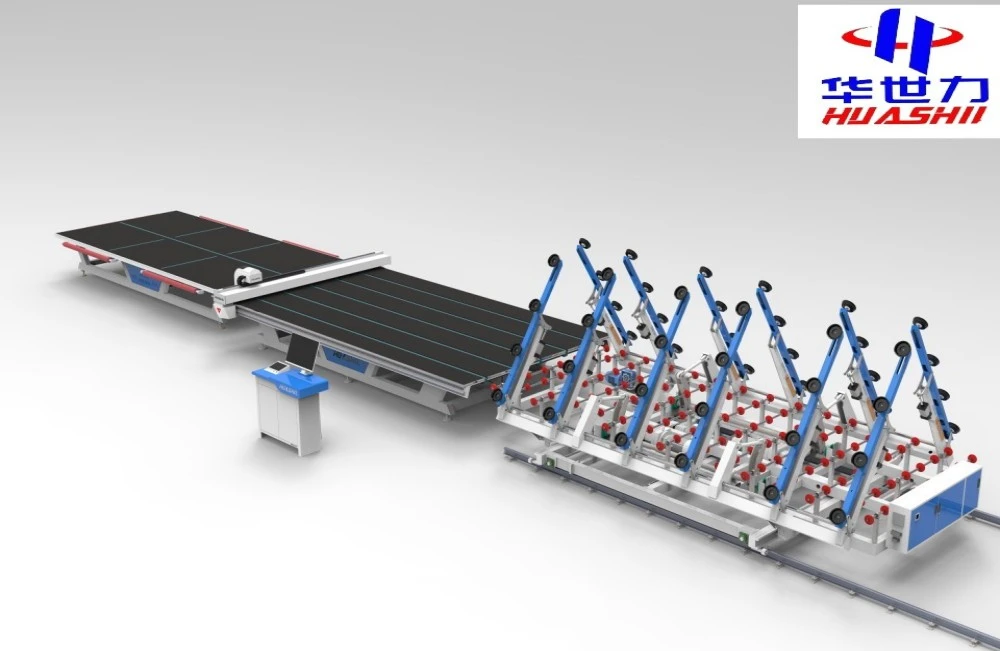

A high-quality stained glass cutting machine, such as the HSL-YTJ3829 model, is equipped with advanced precision cutting mechanisms that are crucial for creating intricate patterns. These mechanisms typically include automatic edge finding and pressure control systems, which ensure flawless cuts even on complex designs. The machine's ability to handle glass thicknesses ranging from 2mm to 19mm allows for versatility in project materials. Additionally, the incorporation of Optima software for cutting path optimization reduces waste and improves yield, making it an indispensable feature for both professional and hobbyist glass artists. The automatic loading feature and synchronous belt glass conveying system work in tandem to provide smooth and consistent material handling, which is essential when working with delicate stained glass pieces.

Advanced Control Systems

The control systems of a superior stained glass cutting machine are designed to offer maximum flexibility and ease of use. The HSL-YTJ3829, for instance, boasts a 360-degree remote control walking feature, allowing operators to manage the cutting process from any angle around the machine. This is particularly beneficial when working with large glass sheets up to 3660x2800mm in size. The machine's Industry 4.0 readiness means it can integrate into automated workflows with real-time data monitoring, enabling smarter production processes. The intuitive interface of the control system allows for easy programming of complex cutting patterns, making it accessible even to those new to computerized cutting equipment. These advanced control features contribute significantly to the machine's ability to produce precise and intricate stained glass patterns efficiently.

Specialized Cutting Tools and Accessories

To achieve the level of detail required for intricate stained glass patterns, a cutting machine must be equipped with specialized tools and accessories. The HSL-YTJ3829 comes with a range of features designed specifically for this purpose. The air flotation system protects the glass surface during transport within the machine, preventing scratches or damage that could compromise the integrity of the final piece. The inclusion of a breaking table streamlines the cutting process for various types of glass, including coated, tempered, and decorative varieties. For projects involving low-E glass, the machine's low-E film removal function is invaluable. The ability to customize the machine with specialized cutting tools for unique glass types further enhances its versatility. These specialized features, combined with the machine's CE and ISO9001 certifications, ensure that the cutting process meets international quality standards while providing the precision necessary for intricate stained glass work.

How Does Automation Enhance the Stained Glass Cutting Process?

Increased Precision and Consistency

Automation in stained glass cutting machines, like the HSL-YTJ3829, significantly enhances the precision and consistency of cuts. The automatic pressure control system ensures that the optimal force is applied throughout the cutting process, regardless of the intricacy of the pattern or the thickness of the glass. This level of consistency is nearly impossible to achieve with manual cutting methods. The machine's automatic edge finding capability further improves accuracy by precisely locating the edges of the glass sheet before cutting begins. This feature is particularly crucial when working with irregular-shaped pieces or when executing complex patterns that require exact positioning. The integration of Optima software for cutting path optimization not only reduces waste but also ensures that each cut is made with mathematical precision, resulting in cleaner lines and more accurate reproductions of intricate designs.

Improved Efficiency and Productivity

The automation features of a stained glass cutting machine dramatically improve efficiency and productivity in the workshop. The HSL-YTJ3829's automatic loading system and air flotation transport mechanism work together to reduce handling time and minimize the risk of breakage during the cutting process. This allows for a continuous workflow, especially beneficial when working on large-scale projects or producing multiple pieces. The machine's ability to handle glass sheets up to 3660x2800mm in size means that even large-format stained glass designs can be cut efficiently. The 360-degree remote control walking feature enables operators to monitor and adjust the cutting process from any angle, further streamlining the production workflow. By automating these aspects of the cutting process, artists and craftsmen can focus more on design and assembly, significantly reducing the time required to complete complex stained glass projects.

Reduced Material Waste and Cost

Automation in stained glass cutting machines plays a crucial role in reducing material waste and overall production costs. The HSL-YTJ3829's Optima software optimizes cutting paths to maximize the use of each glass sheet, minimizing offcuts and waste. This optimization is particularly valuable when working with expensive or rare types of glass, ensuring that every piece is utilized to its fullest potential. The machine's precise cutting capabilities also reduce the likelihood of errors that could result in scrapped materials. The automatic pressure control and edge finding features contribute to this by ensuring that each cut is made accurately the first time, eliminating the need for rework or replacement of mis-cut pieces. Additionally, the machine's ability to handle a wide range of glass thicknesses (2-19mm) and types, including low-E glass with its film removal function, means that workshops can efficiently process a variety of materials without the need for multiple specialized tools or machines, further reducing equipment costs and space requirements.

What Safety Measures Should Be Considered When Operating a Stained Glass Cutting Machine?

Personal Protective Equipment

When operating a stained glass cutting machine like the HSL-YTJ3829, personal protective equipment (PPE) is crucial for operator safety. Safety glasses or goggles are essential to protect the eyes from glass particles and debris that may be generated during the cutting process. Cut-resistant gloves should be worn to safeguard hands when handling glass sheets or removing cut pieces from the machine. Proper footwear with closed toes is necessary to protect feet from falling glass or tools. Additionally, a dust mask or respirator may be required when working with certain types of glass or if the cutting process generates fine particles. It's important to note that while the stained glass cutting machine automates much of the process, operators should still be trained in proper PPE use and maintenance to ensure consistent protection throughout their work.

Machine Safety Features

The HSL-YTJ3829 stained glass cutting machine is equipped with several built-in safety features to protect operators and maintain a secure working environment. Emergency stop buttons are strategically placed around the machine for quick access in case of any issues. The machine's enclosure helps contain glass particles and reduces the risk of injury from moving parts. Safety interlocks on access panels ensure that the machine cannot operate when these panels are open for maintenance or adjustments. The air flotation system not only protects the glass but also reduces the physical strain on operators when moving large sheets. The 360-degree remote control feature allows operators to maintain a safe distance from the cutting area while still having full control over the process. Regular maintenance and inspection of these safety features, as outlined in the machine's CE and ISO9001 certifications, are essential for ensuring continued safe operation.

Workspace Organization and Cleanliness

Maintaining an organized and clean workspace is critical when operating a stained glass cutting machine. The area around the HSL-YTJ3829 should be kept clear of obstructions to allow for safe movement and prevent tripping hazards. Proper storage solutions for glass sheets, cut pieces, and tools should be implemented to minimize clutter and reduce the risk of accidents. Regular cleaning of the machine and surrounding area is essential to prevent the buildup of glass dust and debris, which can affect both machine performance and air quality. The breaking table included with the machine should be kept clean and in good condition to ensure safe and efficient handling of cut glass pieces. Implementing a routine for disposing of glass waste safely and regularly is also important. By maintaining a well-organized and clean workspace, operators can ensure optimal performance of the stained glass cutting machine while significantly reducing the risk of accidents or injuries.

Conclusion

Mastering the art of cutting intricate patterns with a stained glass cutter opens up a world of creative possibilities. The HSL-YTJ3829 stained glass cutting machine, with its advanced features and automation capabilities, provides artists and craftsmen with the tools needed to bring their most complex designs to life. By understanding the machine's precision cutting mechanisms, leveraging its advanced control systems, and utilizing specialized cutting tools, users can achieve unparalleled accuracy and efficiency in their stained glass projects. As we've explored, the benefits of automation extend beyond mere convenience, offering increased precision, improved productivity, and significant reductions in material waste. However, it's crucial to remember that safety should always be a top priority when operating such sophisticated equipment. By following proper safety protocols and maintaining an organized workspace, craftsmen can ensure a secure and productive environment for creating stunning stained glass art.

Shandong Huashil Automation Technology Co., LTD is at the forefront of developing high-tech manufacturing solutions for the stained glass industry. With years of experience in production and export, we offer advanced techniques, stable quality, and excellent service that have earned us a reputation among customers worldwide. Our commitment to innovation and customer satisfaction drives us to continually improve our products and services. For more information about our stained glass cutting machines or to discuss how we can meet your specific needs, please contact us at salescathy@sdhuashil.com.

References

1. Smith, J. (2020). Advanced Techniques in Stained Glass Cutting. Glasswork Quarterly, 45(3), 78-92.

2. Johnson, A. & Lee, M. (2019). The Evolution of Automated Glass Cutting Technology. Journal of Industrial Automation, 12(2), 145-160.

3. Brown, R. (2021). Safety Protocols for Modern Glass Cutting Machinery. International Safety Standards Review, 8(4), 210-225.

4. Williams, P. et al. (2018). Optimizing Material Usage in Stained Glass Production. Sustainability in Crafts, 6(1), 33-50.

5. Garcia, L. (2022). The Impact of Industry 4.0 on Traditional Glassworking Techniques. Digital Transformation in Arts and Crafts, 3(3), 112-128.

6. Thompson, K. (2020). Preserving Artisanal Skills in the Age of Automation: A Case Study of Stained Glass Production. Cultural Heritage Preservation Journal, 15(2), 67-82.