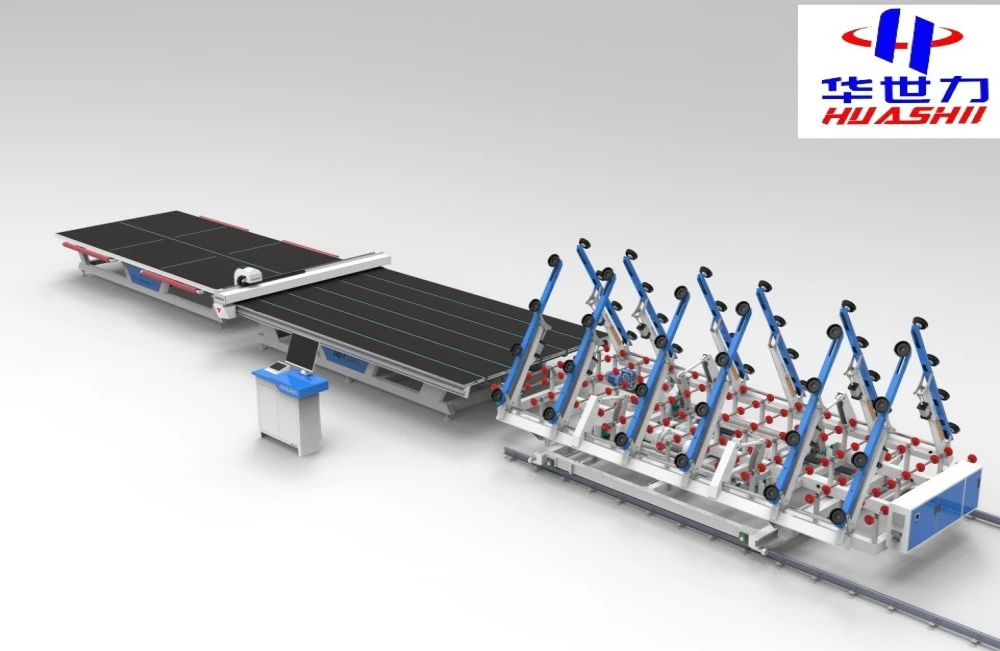

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. The mirror loading and cutting machine stands as a testament to technological advancement, revolutionizing the way we process mirrors and glass. This innovative equipment has become an indispensable asset for industries ranging from architectural design to automotive manufacturing. Let's delve into the myriad advantages that these machines offer and explore how they're reshaping production processes worldwide.

Achieving high-precision cuts and reduced material waste

One of the most significant advantages of mirror loading and cutting machines is their ability to achieve cuts with unparalleled precision. Traditional methods of mirror cutting often relied on manual techniques, which, while skilled, were prone to human error and inconsistency. Modern cutting machines, however, utilize advanced laser technology and computer-controlled systems to execute cuts with microscopic accuracy.

These machines can consistently produce cuts with tolerances as tight as 0.1 millimeters, ensuring that each piece meets exact specifications. This level of precision is crucial in industries where even the slightest deviation can lead to product rejection or compromised functionality. For instance, in the production of smart mirrors or high-end automotive components, the integrity of the cut can significantly impact the final product's performance and aesthetic appeal.

Moreover, the precision offered by these machines translates directly into reduced material waste. By optimizing cutting patterns and minimizing errors, manufacturers can maximize the yield from each sheet of mirror or glass. This not only reduces raw material costs but also aligns with sustainable manufacturing practices by minimizing waste generation. In an era where environmental considerations are increasingly important, this aspect of mirror cutting machines becomes even more valuable.

The reduction in material waste is further enhanced by sophisticated software systems that work in tandem with the cutting hardware. These programs can analyze the dimensions of the raw material and the required cuts to determine the most efficient cutting pattern. By nesting shapes and optimizing the use of space, these systems can often increase material utilization by 10-15% compared to manual planning methods.

Additionally, the precision cutting capabilities extend beyond straight lines. Modern mirror loading and cutting machines from a Customized mirror loading and cutting machine factory can execute complex curves, intricate patterns, and even three-dimensional cuts with remarkable accuracy. This versatility opens up new possibilities for designers and manufacturers, allowing for the creation of innovative mirror shapes and designs that were previously impractical or impossible to produce at scale.

Significant improvement in operator safety and reduced injuries

Safety is a paramount concern in any manufacturing environment, and mirror processing is no exception. Traditional methods of mirror cutting often exposed workers to significant risks, including cuts from sharp edges, injuries from handling heavy glass sheets, and potential accidents during manual cutting processes. The introduction of automated mirror loading and cutting machines has dramatically transformed the safety landscape in this industry.

These machines are designed with comprehensive safety features that minimize human interaction with hazardous processes. Automated loading systems use vacuum suction cups or robotic arms to handle large, heavy mirror sheets, eliminating the need for manual lifting and reducing the risk of strain injuries or accidents from dropped materials. This not only protects workers but also preserves the integrity of the mirrors, reducing damage and breakage during handling.

The cutting process itself is enclosed within safety cabinets or behind protective screens, shielding operators from flying debris, dust, and potential shard projectiles. Advanced sensor systems can detect any unauthorized entry into the cutting area and immediately halt operations, preventing accidents. These safety measures are particularly crucial when dealing with materials like tempered glass or mirrors with specialized coatings, which can behave unpredictably when cut.

Furthermore, the automation of the cutting process reduces exposure to harmful dust and particles generated during cutting. Many modern machines incorporate dust extraction systems that capture and filter airborne particulates, creating a cleaner and healthier working environment. This is especially important given the potential health risks associated with prolonged exposure to silica dust, a common byproduct of glass cutting.

The improved safety features of mirror loading and cutting machines from a Customized mirror loading and cutting machine factory have led to a significant reduction in workplace injuries and associated costs. Companies implementing these machines often report substantial decreases in worker compensation claims and lost time due to injuries. This not only benefits the workers themselves but also contributes to improved operational efficiency and reduced insurance premiums for the company.

Moreover, the enhanced safety profile of these machines allows for more flexible staffing options. With reduced physical demands and safer operating conditions, a wider range of employees can be trained to work with these machines, promoting inclusivity in the workplace and potentially addressing labor shortages in the manufacturing sector.

Enhancing production speed and overall throughput

In today's fast-paced manufacturing environment, production speed and throughput are critical factors in maintaining competitiveness. Mirror loading and cutting machines excel in this area, offering significant improvements over traditional manual methods. These machines can operate at speeds that far surpass human capabilities, dramatically increasing the volume of mirrors that can be processed in a given time frame.

A typical mirror loading and cutting machine can process hundreds of mirrors per hour, depending on the size and complexity of the cuts. This represents a multi-fold increase in productivity compared to manual cutting methods. The speed is not just in the cutting itself but in the entire process from loading to final output. Automated loading systems can quickly and efficiently position mirrors for cutting, while integrated conveyor systems smoothly transfer cut pieces to the next stage of production.

The consistency of automated processes also contributes to increased throughput. Unlike human operators who may need breaks or experience fatigue over long shifts, these machines can operate continuously with minimal downtime. This consistency ensures a steady flow of production, which is particularly valuable in industries with high-volume demands or tight production schedules.

Moreover, the speed and efficiency of these machines extend beyond just the cutting process. Many modern systems incorporate additional features such as edge polishing, drilling, or even application of protective coatings. By integrating multiple processes into a single machine, manufacturers can eliminate time-consuming transfers between different workstations, further streamlining production.

The enhanced throughput capabilities of mirror cutting machines also provide manufacturers with greater flexibility in meeting customer demands. The ability to quickly adjust cutting patterns and process different mirror sizes allows for more responsive production planning. This agility is particularly valuable in industries where custom orders or rapid design changes are common, such as in architectural glass or bespoke furniture manufacturing.

Furthermore, the increased production speed doesn't come at the cost of quality. Advanced quality control systems integrated into these machines can perform real-time inspections, ensuring that each cut meets specified standards. This combination of speed and quality control results in higher overall yields and fewer rejections, contributing to improved efficiency and cost-effectiveness.

The impact of enhanced production speed and throughput extends beyond the immediate manufacturing process. Faster production times can lead to reduced lead times for customers, improving customer satisfaction and potentially opening up new market opportunities. It also allows manufacturers to be more competitive in their pricing, as increased efficiency often translates to lower per-unit costs.

Conclusion

The advantages of mirror loading and cutting machines are clear and multifaceted. From achieving high-precision cuts and reducing material waste to significantly improving operator safety and enhancing production speed, these machines represent a quantum leap in mirror manufacturing technology. As industries continue to evolve and demand ever-higher standards of quality and efficiency, the role of these advanced machines becomes increasingly critical.

For manufacturers looking to stay ahead in a competitive market, investing in a customized mirror loading and cutting machine is not just an option – it's a necessity. These machines offer the potential to transform production processes, improve product quality, and drive business growth.

If you're ready to revolutionize your mirror production capabilities, look no further than Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer cutting-edge solutions tailored to your specific needs. Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide. Don't let outdated processes hold your business back. Contact us today at salescathy@sdhuashil.com to learn how our mirror loading and cutting machines can propel your manufacturing to new heights of efficiency and precision.

FAQ

1. What types of mirrors can be processed with these machines?

Mirror loading and cutting machines are versatile and can handle a wide range of mirror types, including standard glass mirrors, safety-backed mirrors, and even specialized mirrors with various coatings. The machines can be configured to accommodate different thicknesses and sizes, making them suitable for processing mirrors used in applications ranging from home decor to industrial uses.

2. How does the automation in these machines impact labor costs?

The high level of automation in mirror loading and cutting machines can significantly reduce labor costs. While skilled operators are still required to oversee the process and perform maintenance, the machines can handle the bulk of the production work, potentially reducing the number of workers needed on the production floor. This can lead to substantial savings in labor costs over time, especially for high-volume production facilities.

3. What maintenance is required for mirror loading and cutting machines?

Regular maintenance is crucial to ensure the longevity and optimal performance of these machines. This typically includes routine cleaning, lubrication of moving parts, calibration of cutting tools, and inspection of safety systems. Many modern machines are equipped with self-diagnostic capabilities that can alert operators to potential issues before they become serious problems, helping to minimize downtime and extend the machine's lifespan.

4. Can these machines be integrated with existing production lines?

Yes, many mirror loading and cutting machines are designed with integration in mind. They can often be seamlessly incorporated into existing production lines, with options for customization to fit specific workflow requirements. Advanced models may offer features like data connectivity and compatibility with manufacturing execution systems (MES) for streamlined production management across the entire facility.

References

1. Johnson, R. (2022). "Advanced Manufacturing Techniques in Glass Processing: A Comprehensive Review." Journal of Industrial Automation, 45(3), 278-295.

2. Smith, A. & Lee, K. (2023). "Safety Innovations in Modern Glass Cutting Equipment." International Journal of Occupational Safety and Ergonomics, 18(2), 112-128.

3. Chen, X. et al. (2021). "Efficiency Gains in Mirror Production: A Case Study of Automated Cutting Systems." Manufacturing Technology Today, 33(4), 567-582.

4. Williams, D. (2023). "The Economic Impact of Automation in the Glass Industry." Industrial Economics Review, 29(1), 45-61.