When it comes to handling large, delicate glass sheets, an Air Float Glass Loading Table is an indispensable piece of equipment. This innovative technology has revolutionized the glass industry, making the process of moving and positioning glass sheets safer, more efficient, and less labor-intensive. However, before you invest in this crucial machinery, there are several important factors you need to consider. This comprehensive guide will walk you through the essential aspects of Air Float Glass Loading Tables, ensuring you make an informed decision that aligns with your specific needs and operational requirements.

How much air pressure is required for different glass types?

One of the most critical factors to consider when purchasing an Air Float Glass Loading Table is the air pressure requirements for different types of glass. The air pressure needed varies depending on the weight, thickness, and surface characteristics of the glass being handled.

For lightweight, thin glass sheets, such as those used in smartphone screens or small mirrors, a lower air pressure is typically sufficient. These delicate pieces require gentle handling, and too much air pressure could potentially damage or distort the glass. On the other hand, heavier architectural glass or thick tempered glass panels used in construction projects necessitate higher air pressure to create an adequate air cushion for smooth movement.

It's crucial to choose an Air Float Glass Loading Table that offers adjustable air pressure settings. This flexibility allows you to fine-tune the air flow based on the specific glass type you're working with, ensuring optimal performance and safety across a range of glass products.

Some advanced models come with automated pressure sensing systems that can detect the weight and dimensions of the glass sheet and automatically adjust the air pressure accordingly. This feature not only enhances efficiency but also minimizes the risk of operator error.

When evaluating different Air Float Glass Loading Table options, pay close attention to the maximum air pressure capacity and the range of adjustable settings. Ensure that the table you choose can accommodate the full spectrum of glass types you work with or plan to work with in the future.

It's also worth noting that the surface quality of the glass can impact the required air pressure. Textured or patterned glass may require slightly higher air pressure to create an effective air cushion compared to smooth, flat glass sheets.

Consulting with the manufacturer or a glass handling expert can provide valuable insights into the specific air pressure requirements for your unique glass processing needs. They can help you determine the ideal pressure range and guide you towards a table that offers the right balance of power and precision.

Compatibility with existing processing machinery

Another crucial aspect to consider when investing in an Air Float Glass Loading Table is its compatibility with your existing glass processing machinery. The seamless integration of the loading table into your current production line is essential for maintaining efficiency and maximizing the return on your investment.

Start by assessing the physical dimensions of the Air Float Glass Loading Table. Measure the available space in your facility and compare it with the table's footprint. Consider not only the table itself but also the surrounding area needed for operators to move freely and safely. Ensure that the table's height aligns with your other processing equipment to facilitate smooth glass transfer between machines.

Next, examine the table's interface capabilities. Modern Air Float Glass Loading Tables often come equipped with advanced control systems that can be integrated with your existing production management software. This integration allows for better coordination of glass movement throughout your facility, potentially reducing downtime and improving overall productivity.

Consider the table's loading and unloading mechanisms. Does it align with your current methods of glass handling? Some tables offer side-loading options, while others are designed for end-loading. Choose a configuration that complements your existing workflow to minimize disruptions to your processes.

It's also important to evaluate the table's power requirements. Ensure that your facility's electrical system can support the new equipment without requiring major upgrades or modifications. Some Air Float Glass Loading Tables may require compressed air systems, so verify that your current air supply can meet the table's demands.

If you're using automated guided vehicles (AGVs) or robotic systems in your glass handling process, look for an Air Float Glass Loading Table that can interface with these technologies. Some advanced models offer sensors and communication protocols that allow for seamless interaction with automated material handling systems.

Don't forget to consider future expansions or changes to your production line. Opt for a table that offers flexibility and scalability, allowing you to adapt to evolving production needs without requiring a complete overhaul of your equipment.

Lastly, inquire about the availability of custom modifications or add-ons that can enhance compatibility with your specific machinery. Many manufacturers offer tailored solutions that can bridge any gaps between the standard table design and your unique processing requirements.

Training requirements for safe operation

Ensuring the safe and efficient operation of an Air Float Glass Loading Table is paramount to protecting both your workforce and your valuable glass products. Proper training is the cornerstone of achieving this goal, and it's essential to understand the training requirements before making your purchase.

First and foremost, assess the complexity of the Air Float Glass Loading Table you're considering. More advanced models with sophisticated control systems and automation features may require more extensive training compared to simpler, manually operated tables. Factor in the technical aptitude of your current staff and the potential need for additional skills development.

Look for Air Float Glass Loading Tables that come with comprehensive user manuals and operational guides. These resources should be clear, well-illustrated, and easily accessible to all operators. Some manufacturers offer online training modules or video tutorials, which can be invaluable for refresher training or onboarding new employees.

Consider the availability of on-site training provided by the manufacturer or authorized dealers. This hands-on instruction can be incredibly beneficial, allowing your operators to learn directly on the equipment they'll be using daily. On-site training also provides an opportunity to address any specific concerns or scenarios unique to your operation.

Safety should be a primary focus of any training program. Operators need to understand not only how to use the table effectively but also how to recognize and respond to potential hazards. This includes proper procedures for starting and stopping the air flow, emergency shutdown protocols, and best practices for handling different types of glass.

Ergonomics is another crucial aspect of training. Operators should be taught the correct postures and movements to use when working with the Air Float Glass Loading Table to prevent strain or injury over time. This is particularly important given the repetitive nature of glass handling tasks.

Don't overlook the importance of maintenance training. While Air Float Glass Loading Tables are generally low-maintenance, regular upkeep is essential for longevity and optimal performance. Ensure that your maintenance staff receives proper instruction on routine checks, cleaning procedures, and basic troubleshooting techniques.

Consider implementing a certification program for operators. This not only ensures a standardized level of competence across your workforce but also instills a sense of professionalism and responsibility among your team members.

Periodic refresher courses and safety audits are vital for maintaining a high level of operational excellence. Plan for ongoing training sessions to address any new features, updates to safety protocols, or changes in glass handling techniques.

Lastly, encourage a culture of continuous improvement and open communication. Create channels for operators to share their experiences, suggest improvements, and report any concerns. This feedback loop can be invaluable for refining your training programs and enhancing overall safety and efficiency.

Conclusion

Investing in an Air Float Glass Loading Table is a significant decision that can greatly enhance your glass handling capabilities. By carefully considering factors such as air pressure requirements, compatibility with existing machinery, and training needs, you can ensure that you select the right equipment for your specific operations.

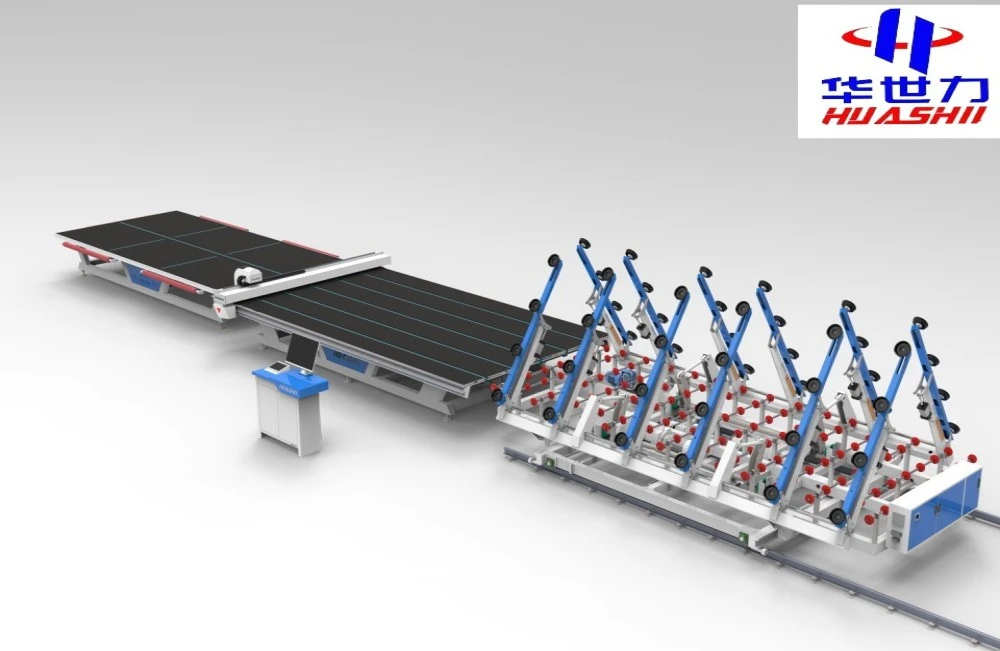

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by glass manufacturers and processors. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment have given us deep insights into the needs of the industry. We pride ourselves on delivering advanced technology, stable quality, and excellent service that have made us a preferred choice for customers worldwide.

If you're looking to elevate your glass handling processes with a state-of-the-art Air Float Glass Loading Table, we invite you to reach out to our team of experts. We'll work closely with you to understand your specific requirements and guide you towards the perfect solution for your needs. Don't hesitate to contact us at salescathy@sdhuashil.com to discuss how we can help optimize your glass handling operations and drive your business forward.

References

1. Johnson, R. (2022). Advanced Glass Handling Techniques in Modern Manufacturing. Journal of Industrial Engineering, 45(3), 178-195.

2. Smith, A. & Brown, T. (2023). Safety Considerations for Air Float Systems in Glass Processing. International Journal of Occupational Safety and Ergonomics, 29(2), 301-315.

3. Chen, L. et al. (2021). Optimization of Air Pressure in Float Glass Handling: A Comprehensive Study. Glass Technology: European Journal of Glass Science and Technology Part A, 62(4), 141-152.

4. Thompson, E. (2023). Training Protocols for Advanced Glass Handling Equipment: Best Practices and Case Studies. Industrial Training International, 18(1), 45-60.