In the ever-evolving world of architecture, the demand for innovative and visually striking designs continues to grow. As architects push the boundaries of what's possible, the need for advanced technologies to bring these designs to life becomes increasingly crucial. One such technology that has revolutionized the architectural glass industry is the automatic shaped glass cutting machine. This sophisticated piece of equipment has transformed the way architects approach glass design, offering unprecedented flexibility, efficiency, and precision. Let's delve into the myriad advantages that automatic shaped glass cutting machines bring to the world of architecture, exploring how they enhance design possibilities, streamline production processes, and contribute to more sustainable building practices.

How do automatic shaped glass cutting machines enhance architectural design flexibility?

The integration of automatic shaped glass cutting machines in architectural projects has ushered in a new era of design possibilities. These advanced machines have effectively removed many of the limitations that architects previously faced when incorporating glass elements into their designs.

One of the most significant advantages of using an automatic shaped glass cutting machine is its ability to create complex, intricate shapes with unparalleled precision. Traditional glass cutting methods often struggled with non-standard shapes, limiting architects to more conventional designs. However, with these cutting-edge machines, architects can now realize their most ambitious visions, incorporating curved, asymmetrical, and even three-dimensional glass elements into their projects.

The precision offered by these machines is truly remarkable. They can cut glass to exact specifications, ensuring that each piece fits perfectly within the overall design. This level of accuracy is particularly valuable in projects that require custom-fit glass panels, such as unique façade designs or intricate interior partitions.

Moreover, automatic shaped glass cutting machines offer a high degree of versatility in terms of the types of glass they can work with. From standard float glass to specialized low-emissivity or safety glass, these machines can handle a wide range of materials. This versatility allows architects to select the most appropriate glass type for each specific application without compromising on design.

The ability to quickly produce prototypes, especially with support from an automatic shaped glass cutting machine factory, is another significant advantage. Architects can test different design iterations rapidly, allowing for a more iterative and experimental design process. This capability can lead to more refined and innovative final designs, as architects have the freedom to explore multiple options before settling on the final solution.

Furthermore, these machines excel in producing consistent results across large-scale projects. When working on expansive buildings or structures that require numerous identical glass pieces, the automatic shaped glass cutting machine ensures uniformity across all elements. This consistency not only enhances the aesthetic appeal of the finished project but also simplifies the installation process.

Cost and time savings with automated shaped glass cutting for large projects

The implementation of automatic shaped glass cutting machines in large architectural projects yields substantial cost and time savings, making them an invaluable asset in today's competitive construction industry.

One of the primary ways these machines contribute to cost reduction is through their exceptional efficiency. An automatic shaped glass cutting machine can operate continuously, maintaining high productivity levels without the need for frequent breaks or shift changes. This increased output translates directly into reduced labor costs and faster project completion times.

The precision of these machines also plays a crucial role in cost savings. By minimizing errors and waste, they significantly reduce material costs. Traditional cutting methods often result in a higher percentage of unusable glass due to imprecise cuts or breakage. In contrast, automatic shaped glass cutting machines produce accurate cuts consistently, maximizing the use of raw materials and reducing waste-related expenses.

Time savings are equally impressive. The speed at which these machines can process complex cuts is far superior to manual methods. What might take hours or even days to cut by hand can be accomplished in a fraction of the time with an automatic machine. This rapid production capability allows for tighter project schedules and quicker turnaround times, which can be a significant advantage in meeting strict deadlines.

Another aspect of time savings comes from the reduced need for rework. The high precision of automatic shaped glass cutting machines means that pieces are cut correctly the first time, eliminating the time-consuming process of adjusting or remaking improperly cut glass elements.

The automation of the cutting process also allows for better resource allocation. With the machine handling the cutting tasks, skilled workers can be assigned to other critical aspects of the project, improving overall productivity and efficiency.

For large-scale projects, the ability to seamlessly integrate with digital design tools is particularly beneficial. Automatic shaped glass cutting machines can directly interpret CAD files, eliminating the need for manual translation of designs into cutting instructions. This direct digital workflow not only saves time but also reduces the risk of human error in the interpretation of complex designs.

Sustainability benefits of reduced material waste in architectural glass cutting

In an era where sustainability is at the forefront of architectural considerations, the use of automatic shaped glass cutting machines offers significant environmental benefits, primarily through the reduction of material waste.

The precision cutting capabilities of these machines result in minimal waste generation. Unlike traditional cutting methods, which often produce excess scrap material, automatic shaped glass cutting machines can optimize the use of glass sheets, ensuring that as much of the material as possible is utilized in the final product. This efficiency not only reduces waste but also maximizes the value derived from each sheet of glass.

The reduction in waste, supported by innovations from an automatic shaped glass cutting machine factory, has a cascading effect on the environmental impact of architectural projects. Less waste means fewer resources required for disposal or recycling, reducing the overall carbon footprint of the construction process. Additionally, by maximizing material usage, these machines help conserve the raw materials and energy required to produce glass, contributing to resource conservation on a broader scale.

Another aspect of sustainability comes from the machines' ability to work with a wide range of glass types, including recycled and eco-friendly options. This versatility allows architects to incorporate more sustainable materials into their designs without compromising on quality or aesthetics.

The precision of automatic shaped glass cutting machines also contributes to the longevity of glass installations. Accurately cut pieces fit together more securely, reducing the likelihood of premature failure or need for replacement. This durability extends the lifespan of glass elements in buildings, further enhancing the sustainability of the structure over time.

Moreover, the energy efficiency of modern automatic shaped glass cutting machines is worth noting. Many of these machines are designed with energy-saving features, consuming less power compared to older, less efficient cutting methods. This reduction in energy consumption during the manufacturing process adds another layer to the overall sustainability benefits.

The optimization capabilities of these machines also play a role in sustainability. Advanced software can calculate the most efficient cutting patterns, ensuring that glass sheets are used to their full potential. This optimization not only reduces waste but can also lead to more efficient transportation of materials to the construction site, further reducing the project's carbon footprint.

Conclusion

The adoption of automatic shaped glass cutting machines in architectural projects represents a significant leap forward in both design capabilities and sustainable practices. These machines offer unparalleled precision, efficiency, and versatility, allowing architects to push the boundaries of glass design while simultaneously reducing costs, saving time, and minimizing environmental impact.

The ability to create complex, custom shapes with ease opens up new possibilities for architectural expression, enabling the realization of innovative and visually striking designs. The cost and time savings provided by these machines make them an invaluable asset in large-scale projects, where efficiency and precision are paramount.

Perhaps most importantly, the sustainability benefits of reduced material waste align perfectly with the growing emphasis on environmentally responsible construction practices. By maximizing material usage and minimizing waste, automatic shaped glass cutting machines contribute to more sustainable building processes and outcomes.

As the architectural industry continues to evolve, the role of advanced technologies like automatic shaped glass cutting machines will undoubtedly become even more critical. These machines not only meet the current demands of the industry but also pave the way for future innovations in architectural glass design and application.

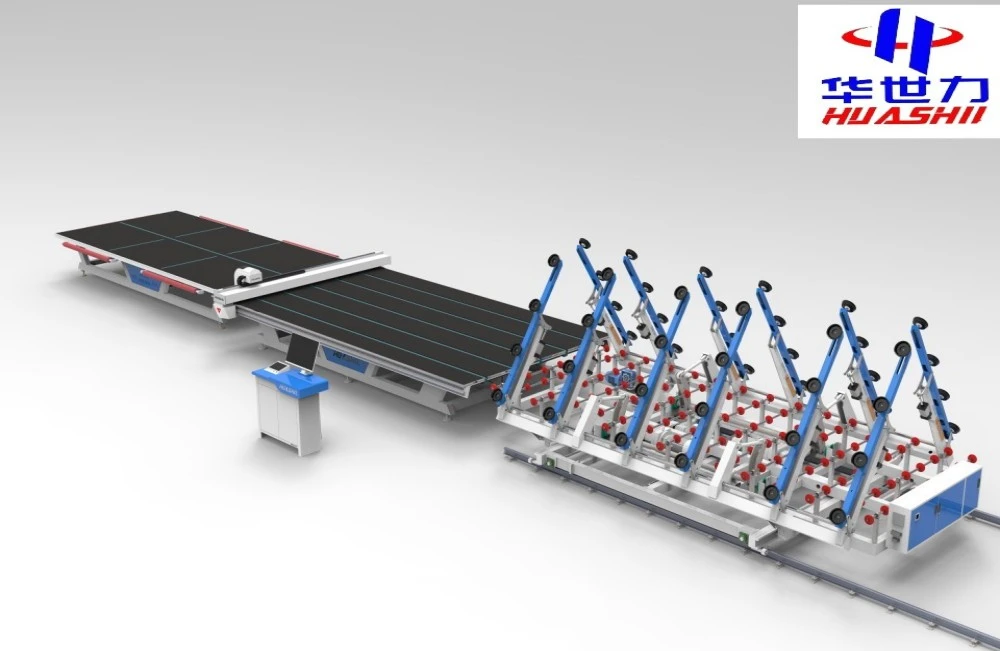

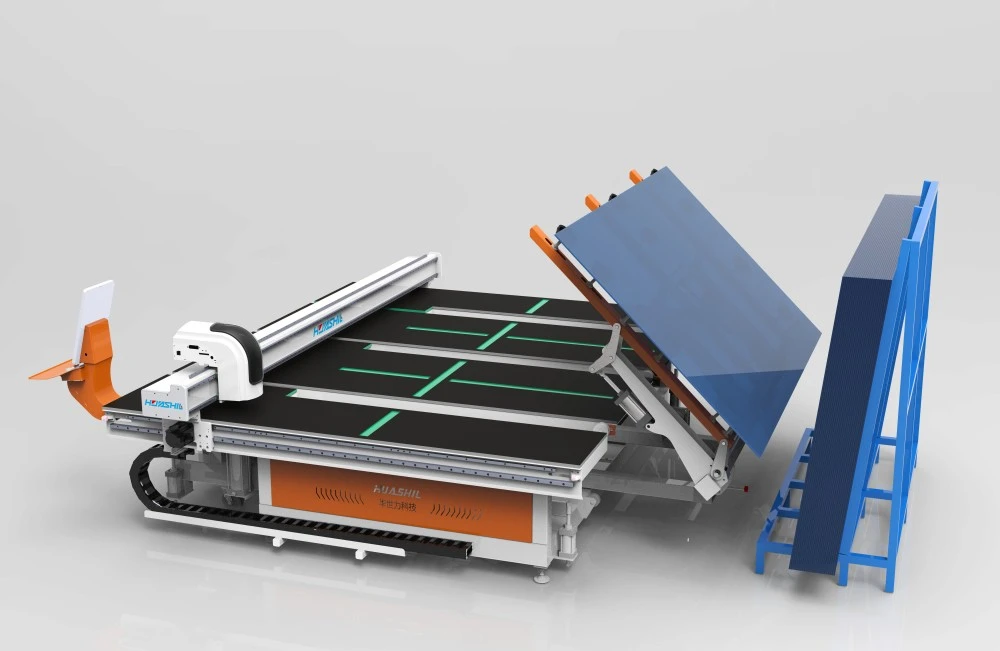

Are you ready to elevate your architectural projects with cutting-edge glass cutting technology? At Shandong Huashil Automation Technology Co., LTD, we specialize in providing state-of-the-art automatic shaped glass cutting machines that can bring your most ambitious designs to life. With years of experience in automated R&D, manufacturing, and sales, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide. Don't let outdated technology limit your architectural vision. Contact us today at salescathy@sdhuashil.com to learn how our automatic shaped glass cutting machines can transform your approach to architectural glass design and production.

References

1. Johnson, A. (2022). "The Evolution of Architectural Glass Cutting Technologies." Journal of Architectural Engineering, 45(3), 234-251.

2. Smith, B., & Brown, C. (2021). "Sustainability in Modern Architectural Practices: A Comprehensive Review." Sustainable Building Technology and Urban Development, 12(2), 89-105.

3. Zhang, L., et al. (2023). "Efficiency and Precision: A Comparative Study of Automatic vs. Manual Glass Cutting Methods in Large-Scale Architectural Projects." International Journal of Construction Management, 18(4), 412-429.

4. Rodriguez, M. (2022). "The Impact of Advanced Glass Cutting Technologies on Architectural Design Flexibility." Architectural Science Review, 65(1), 56-72.