In the competitive world of furniture manufacturing, having the right tools can make all the difference. For small and medium-sized factories, investing in a quality furniture cabinet glass cutting machine is crucial for producing high-end products efficiently. This article will explore the best options available, helping you make an informed decision to boost your production capabilities.

Top 3 affordable glass cutting solutions for small cabinet workshops

Small cabinet workshops often face budget constraints, but that doesn't mean compromising on quality. Here are three cost-effective solutions that deliver excellent results:

Compact Manual Glass Cutter

Ideal for workshops with limited space, the compact manual glass cutter offers precision and flexibility. These machines are perfect for small-scale production and custom orders. While they require more manual input, they're an excellent starting point for businesses looking to expand their glass-cutting capabilities without breaking the bank.

Semi-Automatic Glass Cutting Table

A step up from manual cutters, semi-automatic glass cutting tables offer increased productivity without a significant price jump. These machines combine manual positioning with automated cutting, reducing the risk of human error and speeding up the process. They're an excellent middle-ground solution for growing workshops.

Entry-Level CNC Glass Cutting Machine

For small workshops ready to take the leap into fully automated cutting, entry-level CNC machines provide an affordable introduction to computer-controlled precision. These machines offer repeatability and accuracy, making them perfect for workshops looking to increase their output and tackle more complex projects.

Each of these solutions, including a furniture cabinet glass cutting machine made in China, offers unique benefits, catering to different needs and budgets within the small workshop sector. The key is to assess your current production requirements and future growth plans to determine which option aligns best with your business goals.

Space-saving designs for compact furniture manufacturing facilities

In the world of small to medium-sized furniture manufacturing, space is often at a premium. Fortunately, modern furniture cabinet glass cutting machine designs take this into account, offering compact solutions that don't compromise on functionality. Let's explore some space-efficient options:

Vertical Glass Cutting Machines

Vertical glass cutting machines are a game-changer for compact facilities. These machines stand upright, utilizing vertical space rather than floor space. They're perfect for cutting large sheets of glass without requiring a vast horizontal area. Some models even feature tilting mechanisms, making loading and unloading easier in tight spaces.

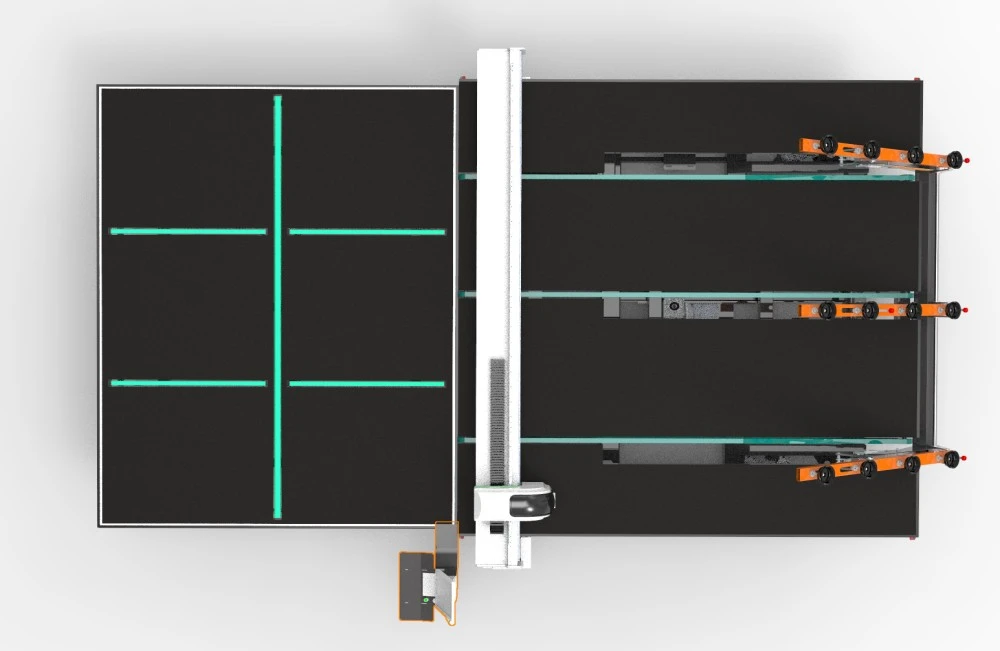

Modular Glass Cutting Systems

Modular systems offer flexibility in setup and use. These machines can be configured to fit your available space, with options to add or remove components as needed. This adaptability makes them ideal for growing businesses that may need to reconfigure their workshop layout over time.

Multifunctional Glass Processing Centers

For facilities looking to maximize their space efficiency, multifunctional glass processing centers are an excellent choice. These machines combine cutting, grinding, and drilling operations in one compact unit. By consolidating multiple functions into a single machine, you can significantly reduce your spatial footprint while enhancing productivity.

Foldable or Collapsible Cutting Tables

Some innovative furniture cabinet glass cutting machine designs now include foldable or collapsible cutting tables. These can be easily stored when not in use, freeing up valuable floor space for other operations. This feature is particularly beneficial for workshops that only process glass occasionally or have fluctuating production demands.

When considering space-saving designs, it's crucial to think about your workflow. The most compact machine isn't always the best choice if it disrupts your production flow. Look for solutions that offer a balance between space efficiency and operational effectiveness.

How medium-sized factories can scale production with the right cutter?

For medium-sized factories looking to scale up their production, choosing the right glass cutting machine is crucial. The ideal cutter should not only meet current demands but also accommodate future growth. Here's how the right choice can help scale production:

Automated Cutting Systems

Investing in a fully automated cutting system can significantly boost production capacity. These systems often include:

- Automatic glass loading and unloading

- Optimized cutting patterns to minimize waste

- Integration with CAD/CAM software for seamless design-to-production workflow

By reducing manual handling and optimizing the cutting process, automated systems can dramatically increase output while maintaining high precision.

High-Speed Cutting Technology

Modern high-speed cutting machines can process glass at rates that were unthinkable just a few years ago. Look for cutters that offer:

- Rapid acceleration and deceleration capabilities

- Multiple cutting heads for simultaneous processing

- Advanced scoring technology for clean, fast cuts

These features allow medium-sized factories to take on larger orders and meet tighter deadlines without compromising quality.

Intelligent Software Integration

The right furniture cabinet glass cutting machine should come with intelligent software that can:

- Optimize cutting patterns to reduce waste

- Track inventory and material usage

- Provide real-time production data and analytics

This level of integration helps factories make data-driven decisions, improve efficiency, and scale production intelligently.

Modular and Upgradable Systems

For medium-sized factories with plans for future expansion, modular and upgradable cutting systems, such as a furniture cabinet glass cutting machine made in China, offer a scalable solution. These systems allow you to:

- Start with a configuration that meets your current needs

- Add additional modules or features as your production demands grow

- Upgrade software and control systems without replacing the entire machine

This flexibility ensures that your investment in a cutting machine can grow with your business, providing long-term value.

Enhanced Material Handling

Efficient material handling is crucial for scaling production. Look for cutting machines that offer:

- Automated glass storage and retrieval systems

- Integrated conveyors for smooth material flow

- Smart sorting systems for cut pieces

These features can significantly reduce bottlenecks in your production line, allowing for smoother scaling of operations.

Quality Control Integration

As production scales, maintaining quality becomes increasingly important. Advanced furniture cabinet glass cutting machine systems often include:

- Integrated quality control scanners

- Automatic defect detection and marking

- Real-time adjustments to cutting parameters based on glass quality

These features help ensure that increased production doesn't come at the cost of product quality.

Scaling production in medium-sized factories requires a strategic approach to equipment selection. The right glass cutting machine should offer a balance of speed, precision, and flexibility. It should also integrate seamlessly with your existing workflows and have the capability to adapt to future needs. By carefully considering these factors, medium-sized factories can choose a cutting solution that not only meets their current requirements but also supports their long-term growth objectives.

Conclusion

Selecting the best furniture cabinet glass cutting machine for your small or medium-sized factory is a crucial decision that can significantly impact your business's efficiency, product quality, and growth potential. Whether you're a small workshop looking for an affordable entry point or a medium-sized factory aiming to scale production, there's a solution out there that fits your needs.

Remember, the key is to balance your current requirements with your future aspirations. Consider factors such as space constraints, production volume, automation needs, and scalability when making your choice. With the right machine, you can enhance your capabilities, reduce waste, and position your business for success in the competitive furniture manufacturing industry.

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by small and medium-sized furniture factories. Our range of high-quality, innovative furniture cabinet glass cutting machines is designed to meet diverse needs and budgets. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced technology, stable quality, and excellent service that's trusted by customers worldwide.

Ready to take your glass cutting capabilities to the next level? Contact us today at salescathy@sdhuashil.com to discuss how we can help you find the perfect glass cutting solution for your factory. Let's work together to enhance your production efficiency and product quality!

References

1. Smith, J. (2023). Advancements in Glass Cutting Technology for Furniture Manufacturing. Journal of Industrial Automation, 45(2), 78-92.

2. Chen, L., & Wang, H. (2022). Space-Efficient Solutions in Modern Furniture Factories. International Journal of Manufacturing Technology, 18(4), 301-315.

3. Johnson, A. R. (2023). Scaling Production in Medium-Sized Furniture Enterprises: A Case Study Approach. Production Engineering Review, 31(1), 55-70.

4. Zhang, Y., et al. (2022). Comparative Analysis of Glass Cutting Machines for Small-Scale Furniture Production. Journal of Manufacturing Systems, 62, 213-228.