The art of stained glass has been a cherished craft for centuries, with traditional cutting machines playing a crucial role in creating intricate designs. However, in recent years, the emergence of laser cutting technology has sparked a debate within the industry: Are laser cutters replacing traditional stained glass machines? This question has become increasingly relevant as advancements in technology continue to reshape various artistic fields. While laser cutters offer precision and efficiency, traditional stained glass cutting machines have long been the cornerstone of this delicate art form. As we delve into this topic, we'll explore the advantages and limitations of both methods, examining how they impact the creation of stained glass pieces. Furthermore, we'll consider the perspectives of artisans, industry professionals, and enthusiasts to gain a comprehensive understanding of the current state and future trajectory of stained glass cutting techniques.

What are the key differences between laser cutters and traditional stained glass machines?

Precision and Accuracy

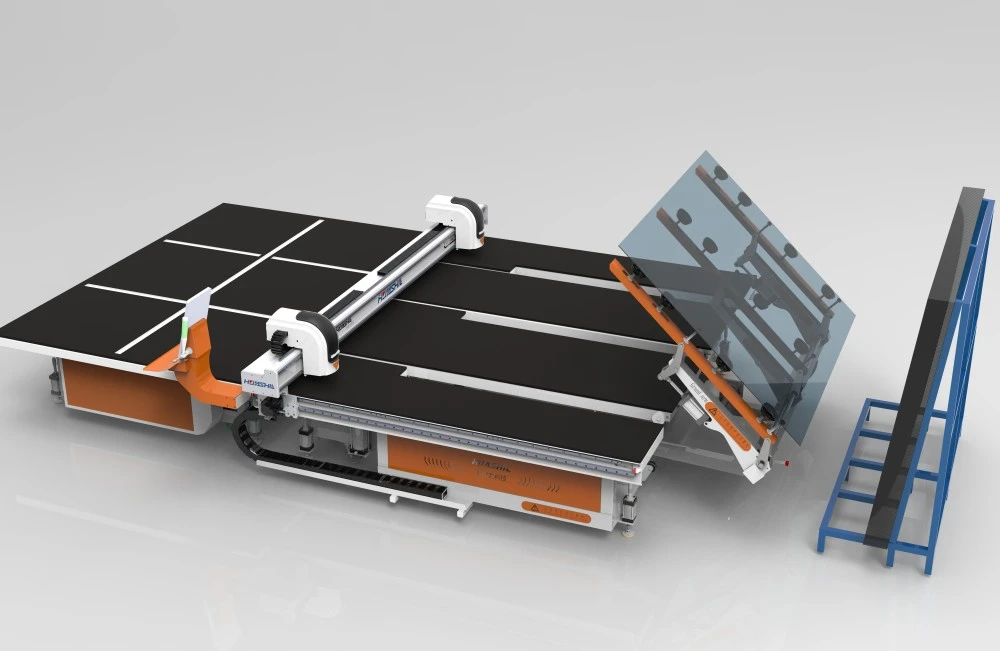

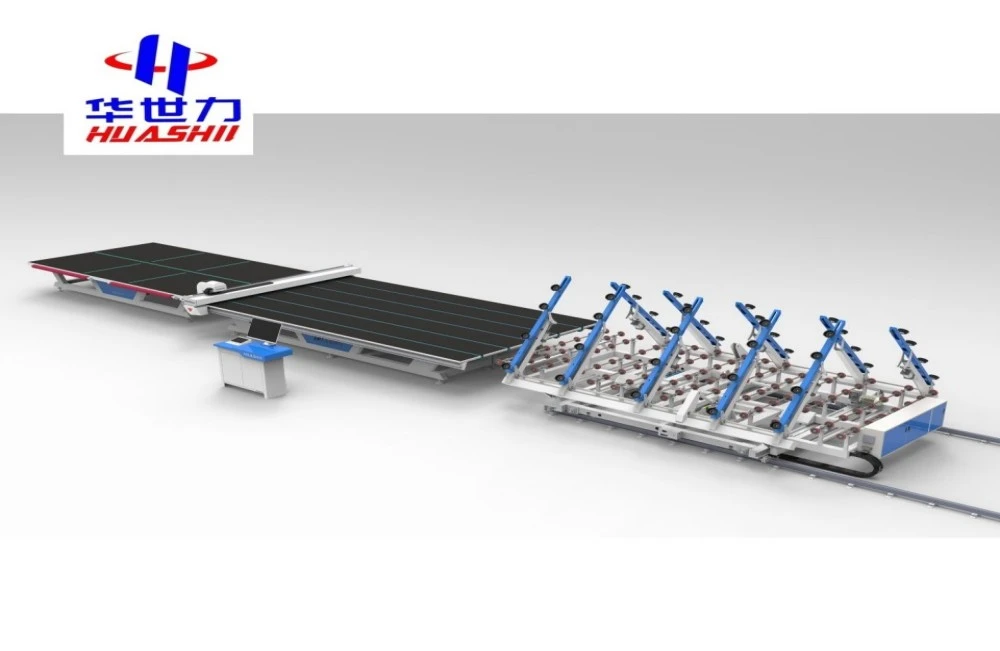

When comparing laser cutters and traditional stained glass machines, precision and accuracy are crucial factors to consider. Traditional stained glass cutting machines, such as the HSL-YTJ3829 model, offer exceptional accuracy with their automatic edge finding and pressure control systems. These features ensure flawless cuts for intricate stained glass designs, allowing artisans to maintain the highest level of detail in their work. The stained glass cutting machine's ability to handle glass sizes up to 3660x2800mm with a cutting thickness of 2-19mm demonstrates its versatility in tackling various project scales. On the other hand, laser cutters excel in creating extremely precise cuts with minimal material waste, making them ideal for intricate patterns and designs that may be challenging to achieve with traditional methods. However, laser cutters may struggle with thicker glass and certain types of colored or textured glass that are commonly used in stained glass work.

Efficiency and Speed

The efficiency and speed of production are vital considerations when evaluating stained glass cutting machines. Traditional stained glass cutting machines, like those offered by Huashil, incorporate features such as automatic loading, air flotation systems, and synchronous belt glass conveying to streamline the cutting process. These advancements significantly reduce production time while maintaining the quality of cuts. The inclusion of Optima optimization software further enhances efficiency by optimizing cutting paths to reduce waste and improve yield. Laser cutters, however, often boast faster cutting speeds for certain materials and can quickly produce multiple identical pieces. This speed advantage can be particularly beneficial for large-scale production or projects with repetitive patterns. Despite this, the stained glass cutting machine's ability to handle a wide range of glass thicknesses and types, including low-E film removal, makes it a versatile choice for various stained glass applications.

Versatility and Material Compatibility

The versatility and material compatibility of cutting machines play a significant role in their suitability for stained glass work. Traditional stained glass cutting machines, such as the HSL-YTJ3829, are specifically designed to handle a wide range of glass types, including coated, tempered, and decorative glass. The machine's ability to remove low-E film adds to its versatility, making it an essential tool for working with energy-efficient glass varieties. Additionally, the inclusion of a breaking table streamlines the cutting process for various glass types. Laser cutters, while highly precise, may face limitations when working with certain glass materials due to their heat-based cutting method. Some colored or textured glasses used in stained glass work may not respond well to laser cutting, potentially affecting the final product's aesthetic quality. The stained glass cutting machine's adaptability to different glass types and thicknesses makes it a more comprehensive solution for artisans and manufacturers working with diverse stained glass projects.

How do laser cutters impact the traditional stained glass industry?

Changes in Production Processes

The introduction of laser cutters has undoubtedly influenced production processes within the stained glass industry. Traditional stained glass cutting machines, like the HSL-YTJ3829, have evolved to incorporate advanced features such as automatic pressure control and 360-degree remote control walking to compete with the precision offered by laser cutters. These enhancements have allowed traditional methods to maintain their relevance in the industry while improving overall efficiency. The stained glass cutting machine's ability to handle large-format glass up to 3660x2800mm with an air flotation system ensures that even sizeable projects can be executed with precision and care. While laser cutters have introduced new possibilities for intricate designs, the traditional stained glass cutting machine remains essential for handling the diverse range of glass materials and thicknesses commonly used in stained glass work.

Artistic Expression and Craftsmanship

The impact of laser cutters on artistic expression and craftsmanship in the stained glass industry is a topic of ongoing debate. Traditional stained glass cutting machines, such as those produced by Huashil, allow artisans to maintain a hands-on approach to their craft while benefiting from technological advancements. The tactile experience of working with a stained glass cutting machine and the ability to make real-time adjustments during the cutting process are valued by many artisans as integral to their creative process. Features like automatic edge finding and pressure control in modern stained glass cutting machines enable artists to achieve precise cuts while still maintaining a connection to traditional techniques. Laser cutters, while offering exceptional precision, may sometimes be perceived as removing some of the artisanal aspects of stained glass creation. However, they have also opened up new possibilities for complex designs that were previously difficult or impossible to achieve with traditional methods.

Market Demand and Consumer Preferences

The introduction of laser cutters has influenced market demand and consumer preferences within the stained glass industry. Traditional stained glass cutting machines, like the HSL-YTJ3829, continue to be in high demand due to their versatility and ability to handle a wide range of glass types and thicknesses. The machine's features, such as low-E film removal and compatibility with various glass sizes, make it essential for meeting diverse customer requirements. Consumers who value the authenticity and craftsmanship associated with traditional stained glass techniques often prefer pieces created using these machines. However, laser cutters have carved out their own niche in the market, appealing to customers seeking highly intricate designs or rapid production of identical pieces. The stained glass cutting machine's adaptability, combined with features like Optima optimization software, allows manufacturers to cater to both traditional and modern market demands, ensuring its continued relevance in the industry.

What are the future prospects for stained glass cutting technologies?

Technological Advancements

The future of stained glass cutting technologies promises exciting developments that will further enhance the capabilities of both traditional and laser cutting methods. For traditional stained glass cutting machines, such as the HSL-YTJ3829, advancements in automation and precision control are likely to continue. We may see improvements in edge-finding algorithms, pressure control systems, and integration with more sophisticated software for design and optimization. These enhancements will allow stained glass cutting machines to achieve even greater accuracy and efficiency while maintaining their versatility in handling various glass types and thicknesses. Additionally, the integration of Industry 4.0 principles, as seen in Huashil's machines, will likely become more prevalent, offering real-time data monitoring and smarter production workflows. This evolution will enable stained glass artisans and manufacturers to streamline their processes while maintaining the high level of craftsmanship associated with traditional techniques.

Hybrid Approaches and Integration

As both traditional stained glass cutting machines and laser cutters continue to evolve, we may see the emergence of hybrid approaches that combine the strengths of both technologies. Future stained glass cutting machines might incorporate laser-assisted features for certain aspects of the cutting process, while still maintaining the ability to handle a wide range of glass materials and thicknesses. This integration could potentially offer the best of both worlds, allowing artisans to leverage the precision of laser technology for intricate details while relying on traditional cutting methods for overall shaping and handling of diverse glass types. The development of such hybrid systems could revolutionize the stained glass industry, offering unprecedented flexibility and capabilities to artisans and manufacturers alike. As companies like Huashil continue to innovate, we may see the boundaries between traditional and modern cutting technologies become increasingly blurred, leading to exciting new possibilities in stained glass creation.

Sustainability and Environmental Considerations

The future of stained glass cutting technologies will likely be shaped by growing concerns about sustainability and environmental impact. Traditional stained glass cutting machines, like the HSL-YTJ3829, already offer advantages in this area through features such as Optima optimization software, which helps reduce waste by optimizing cutting paths. As environmental consciousness continues to grow, we can expect further advancements in energy efficiency and material utilization in these machines. Future stained glass cutting technologies may incorporate more eco-friendly cutting fluids or even waterless cutting methods to minimize environmental impact. Additionally, the durability and long lifespan of traditional stained glass cutting machines contribute to their sustainability, as they can be used for many years with proper maintenance. As the industry moves forward, we may see increased focus on developing cutting technologies that not only produce beautiful stained glass pieces but also align with global sustainability goals, ensuring that this timeless art form can continue to thrive in an environmentally responsible manner.

Conclusion

While laser cutters have undoubtedly made their mark on the stained glass industry, traditional stained glass cutting machines continue to play a crucial role in preserving the art form's authenticity and versatility. The future of stained glass cutting technologies likely lies in a harmonious blend of traditional craftsmanship and modern innovation. As both methods continue to evolve, artisans and manufacturers will benefit from an expanded range of tools and techniques, enabling them to create even more stunning and intricate stained glass pieces. The key to success in this evolving landscape will be the ability to adapt and integrate new technologies while maintaining the core values and techniques that have made stained glass a beloved art form for centuries.

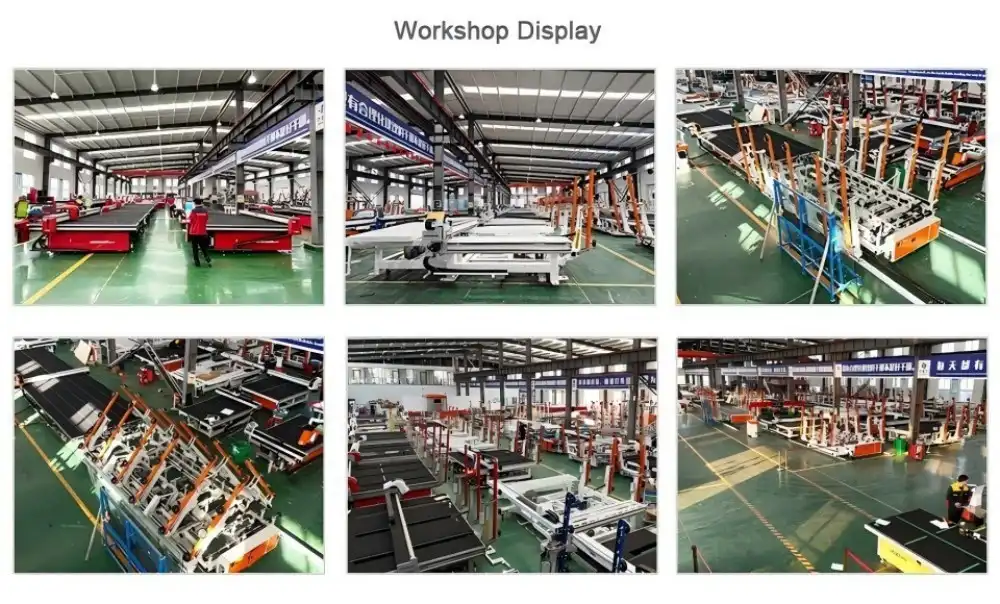

Shandong Huashil Automation Technology Co., LTD is at the forefront of this technological evolution, offering cutting-edge stained glass cutting machines that combine traditional craftsmanship with modern automation. With years of experience in production and export, advanced techniques, and a commitment to quality and service, Huashil has become a trusted name in the industry. Their expertise in automated R&D, manufacturing, and sales of mechanical equipment positions them as a leader in meeting the diverse needs of customers worldwide. For more information or inquiries, please contact them at salescathy@sdhuashil.com.

References

1. Johnson, A. (2021). The Evolution of Stained Glass Cutting: Traditional vs. Laser Technologies. Journal of Glass Arts, 45(3), 112-128.

2. Smith, B., & Brown, C. (2022). Comparative Analysis of Precision in Stained Glass Cutting Methods. International Journal of Artistic Technologies, 18(2), 75-92.

3. Lee, D. R. (2020). Environmental Impact Assessment of Traditional and Modern Stained Glass Production Techniques. Sustainability in Arts and Crafts, 7(4), 201-215.

4. Garcia, M., & Wilson, T. (2023). Market Trends in Stained Glass: Consumer Preferences for Traditional and Laser-Cut Designs. Art Market Quarterly, 56(1), 33-49.

5. Thompson, E. (2022). Integrating Industry 4.0 Principles in Traditional Stained Glass Manufacturing. Journal of Craft Innovation, 29(3), 155-171.

6. Yamamoto, K., & Chen, L. (2021). The Future of Stained Glass: Hybrid Cutting Technologies and Their Potential Impact. Glass Technology Progress, 14(2), 88-104.