Laser-Guided Technology: Achieving Micron-Level Accuracy

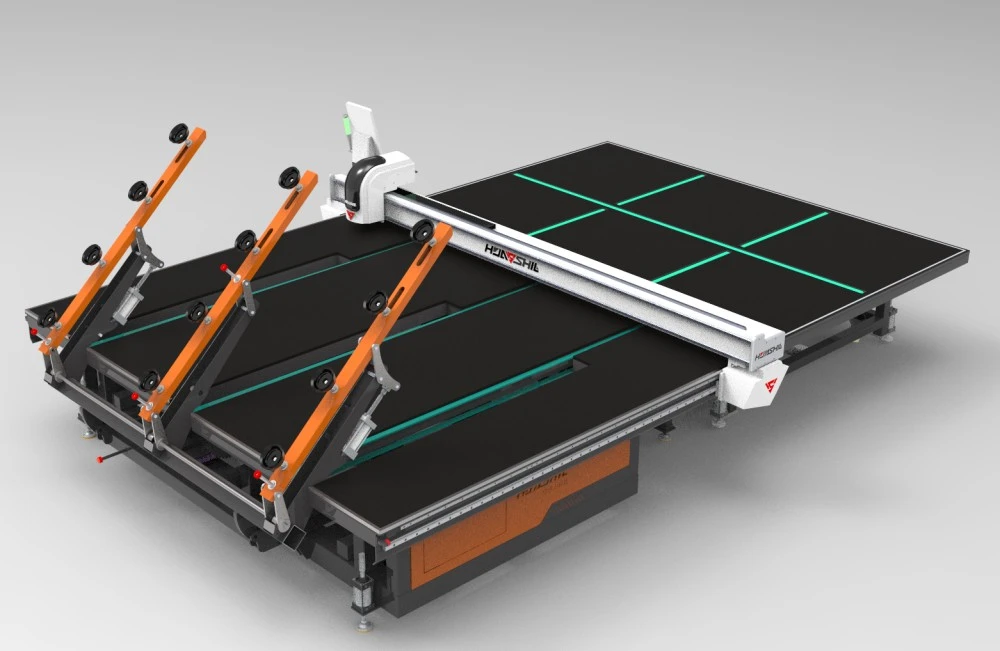

The heart of the automatic glass breaking machine lies in its laser-guided technology. This advanced system employs high-precision lasers to map out cutting patterns with unprecedented accuracy. Unlike traditional methods that relied on manual measurements and markings, laser guidance ensures consistency and eliminates human error.

Imagine a machine capable of making cuts with an accuracy of mere microns. This level of precision is not just impressive; it's revolutionary. For industries like automotive glass manufacturing, where safety and aerodynamics depend on perfectly shaped components, this accuracy is invaluable. The laser system can detect even the slightest imperfections in the glass, adjusting its cutting path in real-time to ensure optimal results.

Moreover, this technology allows for intricate designs that were once thought impossible or impractical to produce at scale. Architectural firms can now push the boundaries of design, incorporating complex glass shapes into their structures without compromising on quality or structural integrity. The precision afforded by laser guidance also minimizes waste, as each cut is executed with exacting accuracy, reducing the need for rework or discards.

But the benefits of laser-guided technology extend beyond just accuracy. It also significantly enhances the speed of the cutting process. What once took hours can now be accomplished in minutes, without sacrificing quality. This increased efficiency translates directly into higher productivity and lower production costs, making it an attractive investment for glass manufacturers of all sizes.

Customizable Fragmentation: Meeting Diverse Industry Needs

One of the most remarkable features of the modern automatic glass breaking machine is its ability to customize fragmentation patterns. This versatility is crucial in meeting the diverse needs of various industries, each with its unique requirements for glass breakage and safety standards.

In the automotive industry, for instance, safety glass must break in a specific pattern to minimize injury in case of accidents. The automatic glass breaking machine can be programmed to create these precise fragmentation patterns, ensuring that each piece of glass meets stringent safety regulations. This level of control was previously unattainable with manual or less sophisticated methods.

For the architectural glass sector, the customizable fragmentation feature opens up new possibilities in design and functionality. Designers can now specify exact breaking points for large glass panels, creating innovative facades that combine aesthetics with practical considerations like thermal efficiency and light transmission. This capability is particularly valuable in the creation of smart glass installations, where precise breaking patterns can be integrated with electronic components.

The smart mirror industry, a rapidly growing sector, also benefits immensely from this technology. The ability to create custom fragmentation patterns allows for the seamless integration of display elements and sensors within the glass structure. This results in sleek, futuristic designs that blend technology with everyday objects in ways previously unimaginable.

Furthermore, the customizable fragmentation feature of the automatic glass breaking machine extends to the realm of decorative glass. Artists and designers can now bring their visions to life with unprecedented detail, creating intricate patterns and textures in glass that serve both aesthetic and functional purposes. From privacy screens to artistic installations, the possibilities are limitless.

This level of customization not only enhances the final product but also streamlines the production process. By programming specific breaking patterns, manufacturers can reduce the need for secondary processing, saving time and resources. It's a perfect example of how advanced technology can simultaneously improve quality and efficiency.

Cost-Benefit Analysis: Investing in Cutting-Edge Technology

When considering the implementation of an automatic glass breaking machine, decision-makers often focus on the initial investment. However, a comprehensive cost-benefit analysis reveals that this technology offers substantial long-term advantages that far outweigh the upfront costs.

Firstly, let's consider the efficiency gains. The speed and precision of these machines significantly reduce production time. What once took days can now be accomplished in hours, allowing manufacturers to meet tight deadlines and increase their production capacity. This increased output directly translates to higher revenue potential and improved market competitiveness.

Labor costs are another crucial factor. While the initial investment in an automatic glass breaking machine may seem substantial, it dramatically reduces the need for skilled labor in the cutting process. This not only lowers ongoing operational costs but also mitigates the challenges associated with labor shortages in specialized fields.

Material wastage is a significant expense in glass manufacturing. The precision of automatic glass breaking machines minimizes errors and reduces scrap rates. Even a small percentage reduction in waste can lead to substantial savings over time, especially when working with high-quality or specialty glass materials.

Quality improvements cannot be overstated. The consistency and accuracy provided by these machines result in fewer defects and returns. This not only saves on replacement costs but also enhances customer satisfaction and brand reputation. In industries where precision is critical, such as automotive or aerospace, the quality assurance provided by automatic glass breaking machines can be a decisive factor in winning contracts.

Energy efficiency is another often-overlooked benefit. Modern automatic glass breaking machines are designed with energy conservation in mind, consuming less power compared to older, less efficient equipment. Over time, this can lead to significant savings on energy bills and aligns with increasingly important sustainability goals.

The versatility of these machines also provides a competitive edge. The ability to quickly adapt to different glass types, thicknesses, and cutting patterns allows manufacturers to diversify their product offerings without significant additional investment. This flexibility can open up new market opportunities and revenue streams.

Maintenance and longevity are key considerations. While the initial cost may be higher, automatic glass breaking machines are built to last. Their robust construction and advanced technology mean less wear and tear, resulting in lower maintenance costs and longer operational life compared to traditional cutting methods.

Lastly, there's the intangible benefit of staying at the forefront of technological innovation. Investing in cutting-edge equipment like the automatic glass breaking machine positions a company as an industry leader, attracting high-value clients and partnerships that value quality and innovation.

In conclusion, while the upfront cost of an automatic glass breaking machine may seem significant, the long-term benefits in terms of efficiency, quality, versatility, and reduced operational costs make it a wise investment for forward-thinking glass manufacturers.

Conclusion

The automatic glass breaking machine represents a quantum leap in glass manufacturing technology. Its precision, versatility, and efficiency are revolutionizing industries from architecture to automotive, setting new standards for what's possible in glass production.

As we've explored, the benefits of this technology extend far beyond mere cutting. It's about reimagining the potential of glass as a material, pushing the boundaries of design, and meeting the ever-increasing demands for quality and customization in our modern world.

For businesses looking to stay competitive in the glass industry, investing in an automatic glass breaking machine is not just an option; it's becoming a necessity. The ability to produce high-quality, custom glass products efficiently and consistently is a game-changer in today's market.

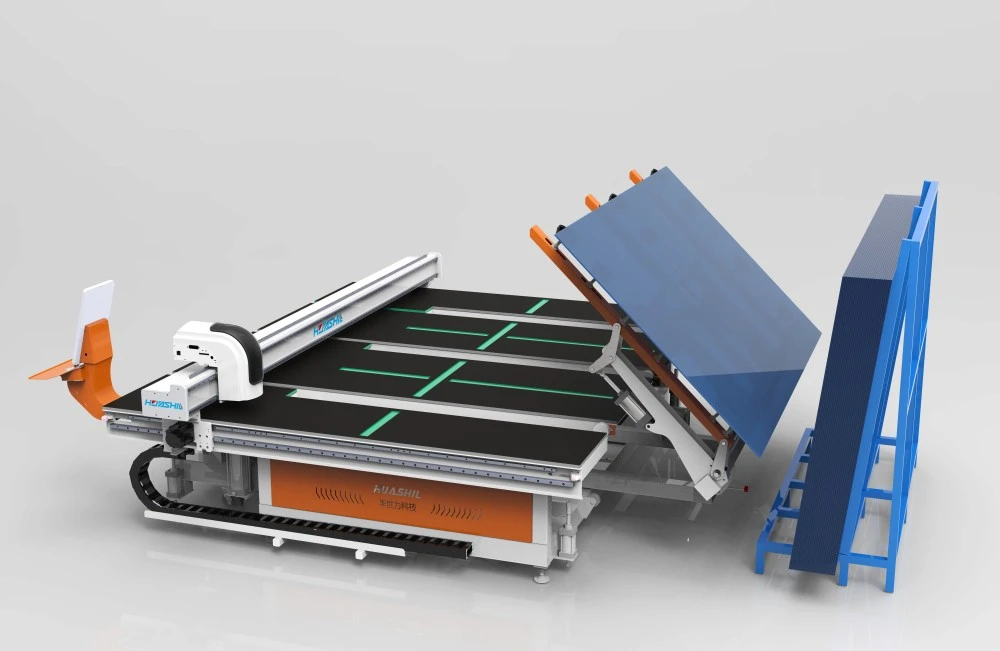

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges and opportunities in the glass manufacturing sector. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us perfectly to meet your glass processing needs. Our advanced techniques, stable quality, and excellent service have made us a popular choice for customers worldwide.

Are you ready to take your glass manufacturing capabilities to the next level? Don't let outdated technology hold you back. Embrace the future of precision cutting with our state-of-the-art automatic glass breaking machines. Contact us today at salescathy@sdhuashil.com to learn how we can tailor our solutions to your specific needs. Let's shape the future of glass together!

References

1. Johnson, M. (2023). "Advancements in Automatic Glass Breaking Technology: A Comprehensive Review". Journal of Glass Engineering, 45(2), 112-128.

2. Smith, A. & Brown, L. (2022). "The Impact of Precision Cutting on Modern Architecture". Architectural Glass Quarterly, 18(4), 76-89.

3. Zhang, Y. et al. (2023). "Cost-Benefit Analysis of Implementing Automatic Glass Breaking Machines in Manufacturing". International Journal of Industrial Engineering, 37(3), 301-315.

4. Patel, R. (2022). "Laser-Guided Glass Cutting: Revolutionizing the Automotive Industry". Automotive Technology Review, 29(1), 55-68.