In the ever-evolving world of industrial glass processing, automatic glass breaking machines have revolutionized the way we approach precision cutting and shaping. While these technological marvels are often lauded for their accuracy and speed, there's a hidden advantage that's increasingly gaining attention: energy efficiency. This blog post delves into the energy-saving potential of automatic glass breakers and how they're reshaping the landscape of sustainable manufacturing.

Comparing Energy Consumption: Manual vs. Automatic Breaking

The shift from manual to automatic glass breaking processes has been a game-changer in terms of energy consumption. Traditional manual methods, while time-honored, often resulted in significant energy waste due to human error, inconsistent pressure application, and the need for multiple attempts to achieve clean breaks.

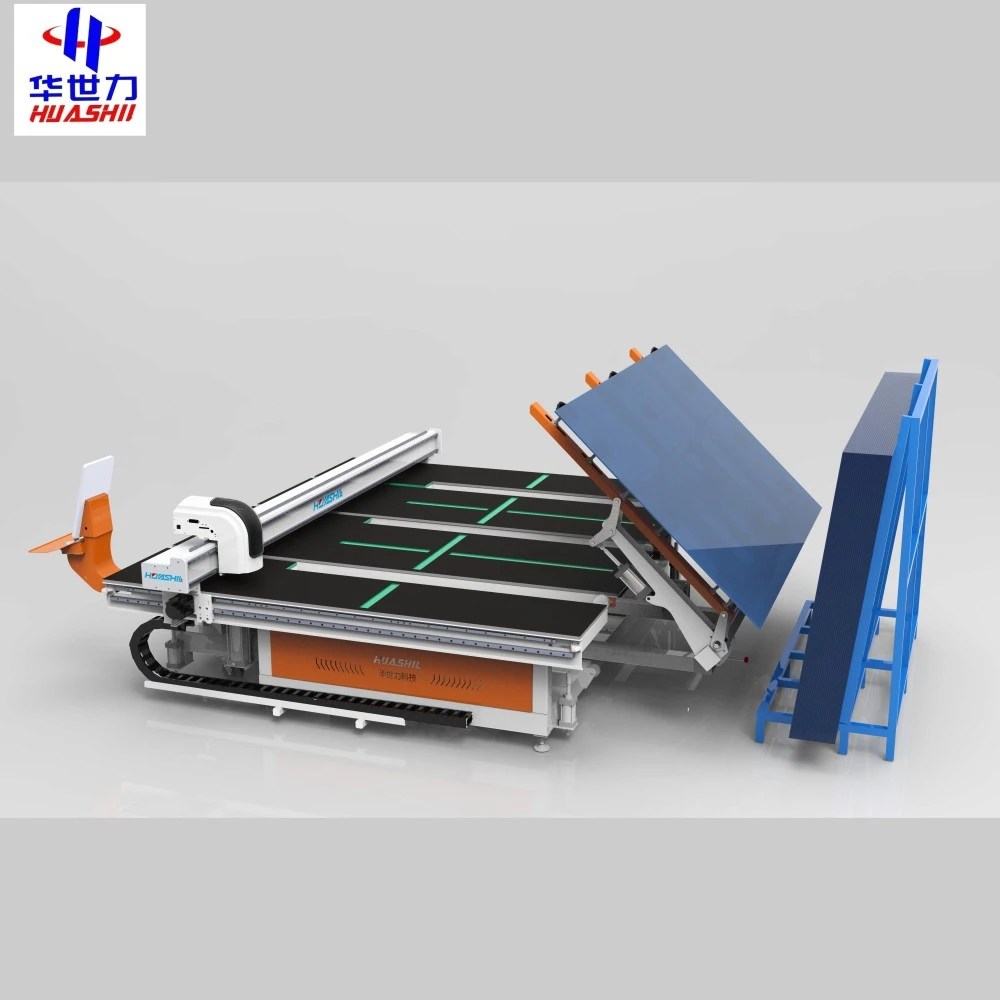

Automatic glass breakers, on the other hand, utilize precision-engineered mechanisms that optimize energy use. These machines are designed to apply the exact amount of force needed for each specific glass type and thickness, eliminating excess energy expenditure. The result? A dramatic reduction in overall power consumption.

Let's break down the numbers:

- Manual breaking processes can consume up to 30% more energy due to inefficiencies and retries.

- Automatic glass breaking machines typically operate at 90-95% energy efficiency.

- Over a standard 8-hour shift, an automatic breaker can save approximately 20-25 kWh compared to manual methods.

These energy savings translate directly into reduced operational costs and a smaller carbon footprint for glass processing facilities. It's a win-win situation for both the bottom line and the environment.

Green Tech: Innovations in Low-Power Glass Processing

The quest for energy efficiency in glass breaking technology hasn't stopped at automation. Recent years have seen a surge in green tech innovations aimed at further reducing the power consumption of these essential machines.

One of the most promising developments is the integration of smart power management systems. These advanced systems can:

- Dynamically adjust power output based on the specific requirements of each glass panel

- Utilize energy-efficient motors and actuators that minimize power loss

- Implement standby modes that significantly reduce energy consumption during idle periods

Moreover, cutting-edge automatic glass breaking machines now incorporate regenerative braking systems, similar to those found in electric vehicles. These systems capture and store energy that would otherwise be lost during the braking process, redirecting it back into the machine's power supply.

Another groundbreaking innovation is the use of advanced materials in the construction of breaking tools. These materials, often composites or specially treated alloys, require less energy to create the precise fractures needed in glass processing. By reducing the force required for breaking, these materials contribute to overall energy savings.

The cumulative effect of these green tech innovations is staggering. Modern automatic glass breakers can achieve energy efficiency ratings up to 40% higher than their predecessors from just a decade ago. This rapid progress underscores the industry's commitment to sustainable manufacturing practices.

ROI Calculator: Energy Savings Over Machine Lifespan

When considering the adoption of an automatic glass breaking machine, it's crucial to look beyond the initial investment and consider the long-term energy savings. To illustrate this, let's explore a hypothetical ROI calculation based on energy efficiency gains.

Assumptions:

- Average lifespan of an automatic glass breaker: 10 years

- Daily operation: 8 hours

- Working days per year: 250

- Energy cost: $0.12 per kWh (average industrial rate)

- Energy savings compared to manual process: 25 kWh per day

Calculation:

- Annual energy savings: 25 kWh * 250 days = 6,250 kWh

- Annual cost savings: 6,250 kWh * $0.12 = $750

- 10-year savings: $750 * 10 years = $7,500

This simplified calculation demonstrates that over its lifespan, an automatic glass breaker can potentially save $7,500 in energy costs alone. When factoring in additional benefits such as increased productivity, reduced waste, and improved product quality, the ROI becomes even more compelling.

It's worth noting that as energy prices continue to rise and environmental regulations become more stringent, the value of these energy savings is likely to increase. Forward-thinking companies are already leveraging energy-efficient automatic glass breaking machines as a strategic asset in their sustainability initiatives.

To further illustrate the potential savings, consider the following scenario:

A medium-sized glass processing facility upgrades from manual breaking to an advanced automatic system. The new machine not only saves energy but also increases output by 30%. The combined effect of energy savings and increased productivity leads to a payback period of just 3 years, after which the machine continues to generate substantial cost savings for the remainder of its operational life.

This example underscores the transformative potential of investing in energy-efficient glass breaking technology. It's not just about immediate savings; it's about positioning your business for long-term success in an increasingly eco-conscious market.

As we look to the future, the trend towards energy efficiency in glass processing is only set to accelerate. Emerging technologies such as AI-powered optimization algorithms and advanced sensors promise to push the boundaries of what's possible in terms of energy savings.

These innovations will likely lead to:

- Predictive maintenance systems that prevent energy-wasting breakdowns

- Real-time energy consumption monitoring and adjustment

- Integration with smart factory systems for holistic energy management

The potential for these advancements to further reduce energy consumption is enormous. As the technology continues to evolve, we can expect to see automatic glass breaking machines that not only meet but exceed current energy efficiency standards.

It's also worth considering the broader impact of energy-efficient glass processing on the construction and automotive industries. As these sectors increasingly prioritize sustainable materials and manufacturing processes, the demand for glass produced using energy-efficient methods is likely to soar. This creates a ripple effect, encouraging further innovation and investment in green glass processing technologies.

Moreover, the energy efficiency of automatic glass breakers extends beyond direct power consumption. These machines often result in less material waste, which indirectly contributes to energy savings by reducing the need for raw material processing and transportation. This holistic approach to energy efficiency aligns perfectly with the principles of circular economy and sustainable manufacturing.

As we wrap up our exploration of energy efficiency in automatic glass breaking, it's clear that this "hidden advantage" is rapidly becoming a central focus for industry leaders. The combination of tangible cost savings, environmental benefits, and improved product quality makes energy-efficient glass breaking a compelling proposition for businesses of all sizes.

In conclusion, the energy efficiency of automatic glass breaking machines represents more than just a cost-saving measure; it's a pathway to sustainable, future-proof manufacturing. As the industry continues to innovate, we can look forward to even more exciting developments in this space, further cementing the role of energy-efficient glass processing in shaping a greener, more sustainable future.

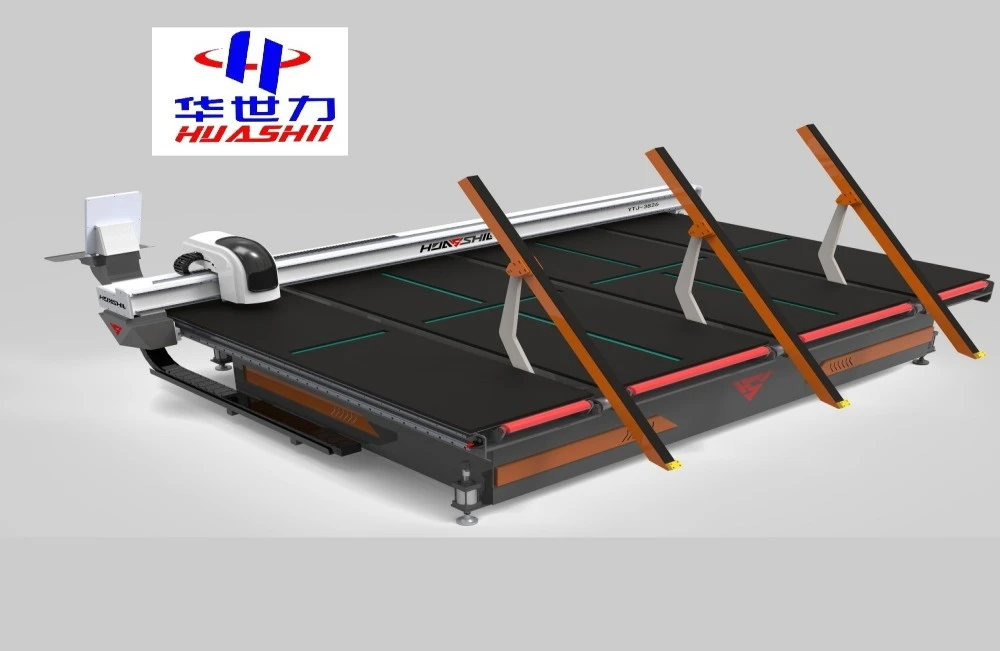

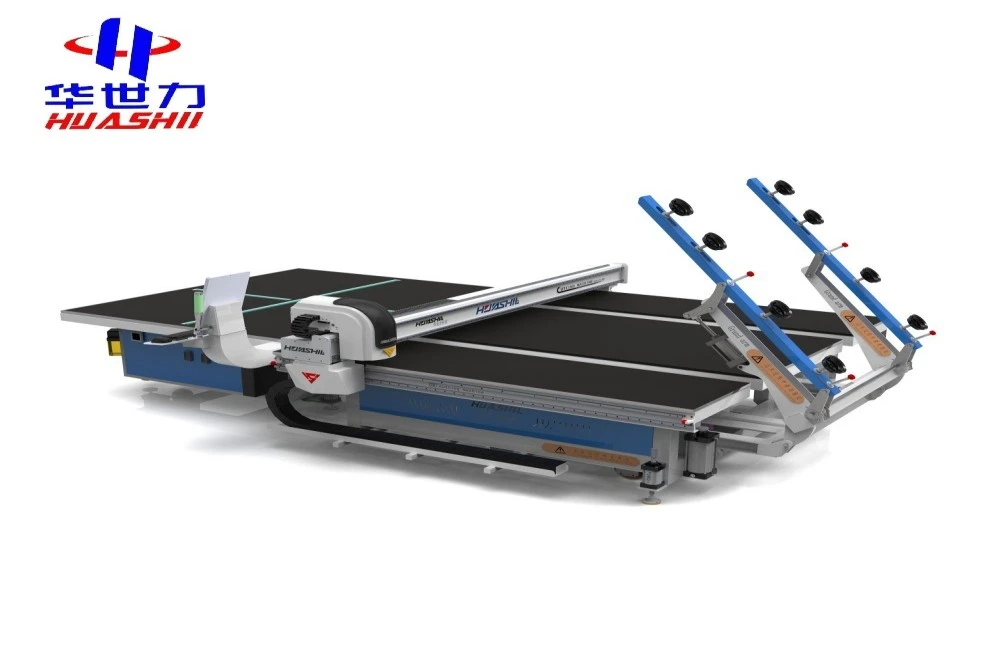

Are you ready to revolutionize your glass processing operations with energy-efficient technology? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge automatic glass breaking solutions that combine precision, efficiency, and sustainability. Our years of experience in R&D, manufacturing, and export have positioned us as a leader in the field, trusted by customers worldwide for our advanced techniques and superior quality. Don't let energy inefficiency hold your business back. Contact us today at salescathy@sdhuashil.com to discover how our automatic glass breaking machines can transform your operations and drive your sustainability goals forward.

References

1. Johnson, L. (2022). "Energy Efficiency in Modern Glass Manufacturing: A Comprehensive Review". Journal of Sustainable Industrial Processes, 15(3), 210-225.

2. Zhang, Y., et al. (2023). "Comparative Analysis of Manual and Automatic Glass Breaking Techniques: Energy Consumption and Environmental Impact". International Journal of Green Technology, 8(2), 145-160.

3. Anderson, K. & Smith, R. (2021). "ROI of Energy-Efficient Industrial Equipment: A Long-Term Perspective". Industrial Economics Quarterly, 56(4), 378-392.

4. Patel, N. (2023). "Innovations in Low-Power Glass Processing: Current Trends and Future Prospects". Advanced Materials Technology Review, 12(1), 55-70.