AI-driven optimization: Reducing human error

One of the most significant advancements in modern CNC glass cutting lines is the integration of artificial intelligence (AI) to optimize cutting processes and minimize human error. AI algorithms analyze vast amounts of data to make real-time decisions, ensuring that each cut is performed with utmost precision and efficiency.

These intelligent systems can:

- Predict optimal cutting paths to maximize material usage and reduce waste

- Adjust cutting parameters based on glass thickness, type, and desired shape

- Identify potential issues before they occur, preventing costly mistakes

- Learn from previous cutting jobs to continuously improve performance

By leveraging AI, manufacturers can achieve unprecedented levels of accuracy and consistency in their glass cutting operations. This not only results in higher-quality products but also significantly reduces material waste and production costs.

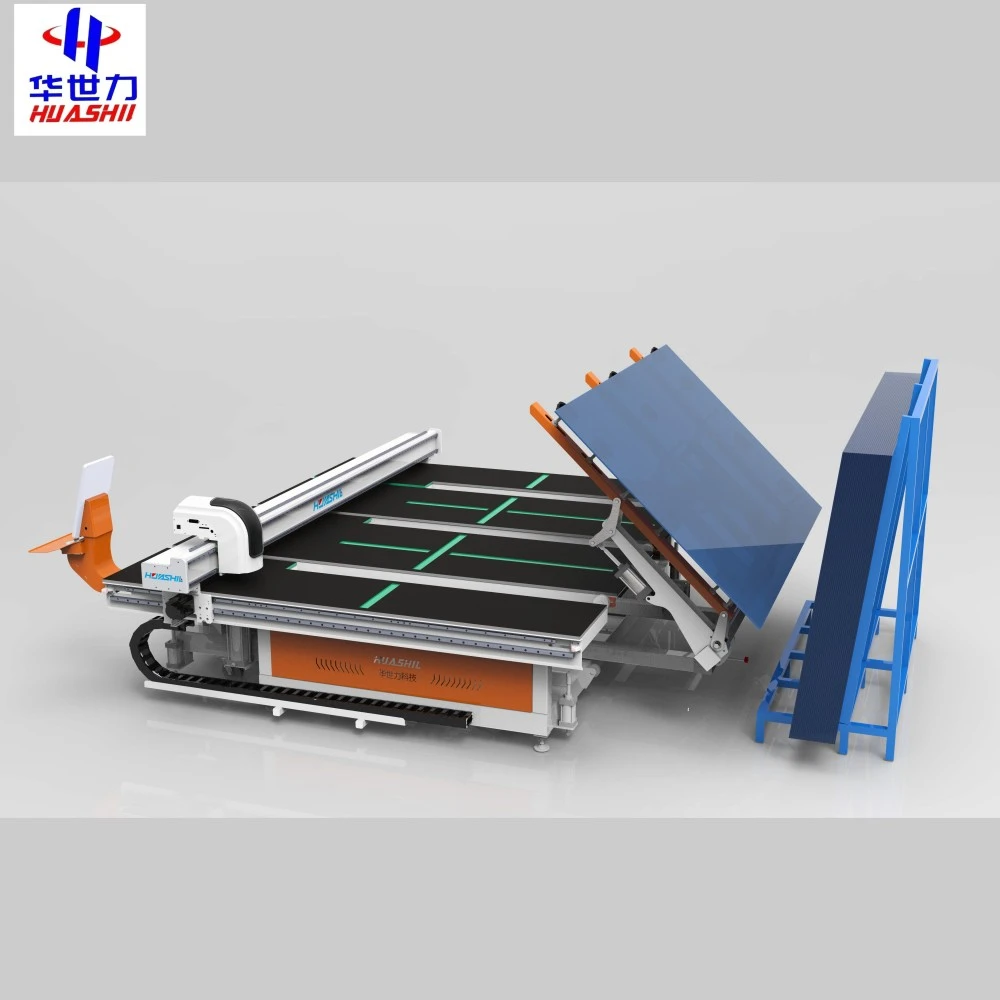

Moreover, AI-driven optimization allows for greater flexibility in production. Customized CNC glass cutting lines can quickly adapt to different glass types, thicknesses, and cutting requirements without the need for extensive manual reprogramming. This versatility is particularly valuable in industries that demand rapid prototyping or small-batch production runs.

24/7 production: The power of robotic assistance

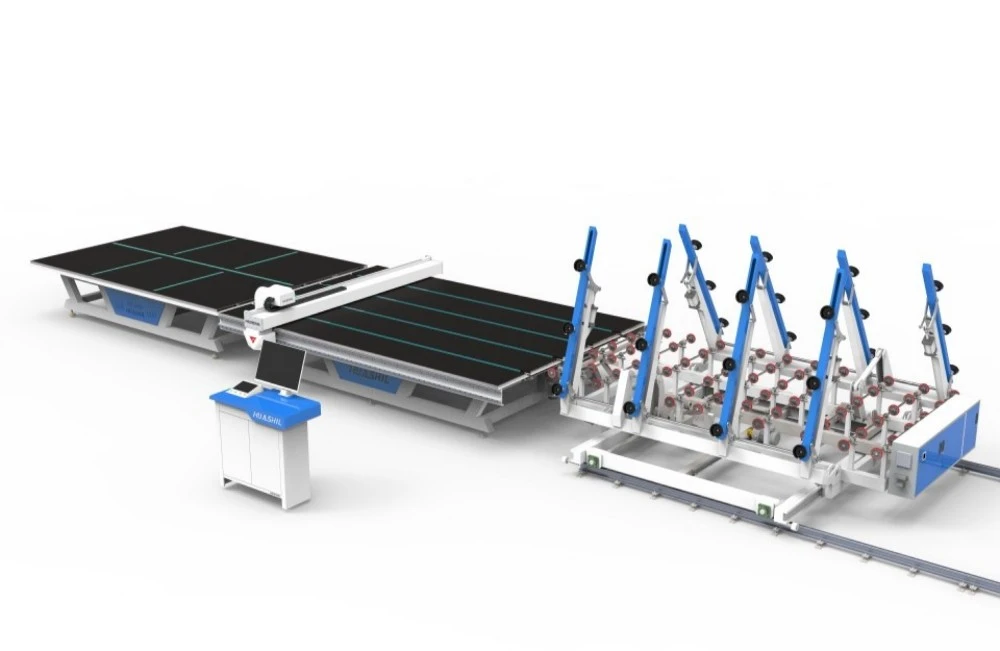

Another game-changing aspect of automation in modern CNC glass cutting lines is the integration of robotic systems. These tireless assistants enable round-the-clock production, dramatically increasing output and efficiency.

Robotic systems in CNC glass cutting lines can perform a variety of tasks, including:

- Loading and unloading glass sheets

- Transferring cut pieces to subsequent processing stations

- Stacking and sorting finished products

- Performing routine maintenance and cleaning tasks

The implementation of robotic assistance not only boosts productivity but also enhances workplace safety. By taking over repetitive and potentially hazardous tasks, robots reduce the risk of workplace injuries and allow human operators to focus on more complex, value-added activities.

Furthermore, robotic systems can work in tandem with AI-driven optimization on a Customized CNC glass cutting line to create a seamless, highly efficient production line. This synergy between intelligent software and advanced hardware is pushing the boundaries of what's possible in glass cutting and processing.

Real-time quality control through automated inspection

Quality control is a critical aspect of glass production, and automation has revolutionized this process as well. Modern CNC glass cutting lines incorporate advanced inspection systems that continuously monitor and assess the quality of cut glass in real-time.

These automated inspection systems utilize:

- High-resolution cameras and sensors

- Machine vision algorithms

- Laser measurement technology

- Spectral analysis for detecting impurities or inconsistencies

By implementing real-time quality control, manufacturers can identify and address issues immediately, preventing defective products from progressing through the production line. This not only saves time and resources but also ensures that only the highest quality glass products reach the end-user.

Automated inspection systems can detect a wide range of defects, including:

- Edge quality issues

- Dimensional inaccuracies

- Surface imperfections

- Stress patterns that may lead to breakage

The data collected by these systems can also be used to fine-tune the cutting process, creating a feedback loop that continuously improves product quality and consistency.

In addition to quality control, automated inspection systems contribute to traceability and documentation. Each piece of glass can be tracked throughout the production process, with detailed records of its quality attributes. This information is invaluable for quality assurance, customer service, and regulatory compliance.

The future of CNC glass cutting: Embracing Industry 4.0

As we look to the future, the automation of CNC glass cutting lines is set to become even more sophisticated with the adoption of Industry 4.0 principles. This next phase of industrial evolution promises to bring about even greater levels of connectivity, data analysis, and autonomous decision-making.

Some exciting developments on the horizon include:

- Internet of Things (IoT) integration for improved machine-to-machine communication

- Predictive maintenance systems that can anticipate and prevent equipment failures

- Virtual and augmented reality tools for operator training and remote assistance

- Cloud-based data analytics for enhanced process optimization across multiple production sites

These advancements will not only further improve efficiency and quality but also enable greater customization and flexibility in glass production. As the demand for specialized glass products continues to grow in industries such as architecture, automotive, and electronics, the ability to quickly adapt and produce custom designs will become increasingly important.

Overcoming challenges in automation implementation

While the benefits of automation in CNC glass cutting lines are clear, implementing these advanced systems can present challenges for manufacturers. Some common hurdles include:

- High initial investment costs

- The need for specialized training and skills development

- Integration with existing systems and workflows

- Ensuring data security and privacy in connected systems

To overcome these challenges, it's crucial for manufacturers to approach automation implementation strategically. This may involve:

- Conducting thorough cost-benefit analyses to justify investments

- Developing comprehensive training programs for employees

- Partnering with experienced automation providers for smooth integration

- Implementing robust cybersecurity measures to protect sensitive data

By addressing these challenges head-on, manufacturers can successfully transition to automated CNC glass cutting lines and reap the numerous benefits they offer.

The environmental impact of automated glass cutting

Automation in CNC glass cutting lines doesn't just benefit manufacturers; it also has positive implications for the environment. By optimizing material usage and reducing waste, automated systems contribute to more sustainable glass production practices.

Some of the environmental benefits include:

- Reduced energy consumption through more efficient cutting processes

- Decreased material waste, leading to conservation of raw materials

- Lower emissions due to optimized production schedules and reduced transportation needs

- Improved recycling capabilities through precise sorting and tracking of glass waste

As sustainability becomes an increasingly important consideration for businesses and consumers alike, the environmental advantages of automated CNC glass cutting lines are likely to become a key selling point for manufacturers adopting this technology.

The human factor: Evolving roles in automated glass production

While automation has undoubtedly transformed the glass cutting industry, it's important to note that human skills and expertise remain crucial. Rather than replacing workers, automation is changing the nature of jobs in the glass industry, creating new opportunities for skilled professionals.

Some of the evolving roles in automated glass production include:

- Automation specialists who design, implement, and maintain CNC systems

- Data analysts who interpret and act on the vast amounts of information generated by automated systems

- Quality assurance experts who oversee and fine-tune automated inspection processes

- Creative designers who push the boundaries of what's possible with advanced glass cutting technology

By embracing these new roles and continuously updating their skills, workers in the glass industry can thrive in the age of automation and contribute to the ongoing innovation in CNC glass cutting technology.

Conclusion

The automation of modern CNC glass cutting lines represents a significant leap forward for the glass industry. From AI-driven optimization and robotic assistance to real-time quality control, these advanced systems are revolutionizing the way glass is processed and manufactured. As we look to the future, the continued evolution of automation technology promises even greater levels of efficiency, quality, and sustainability in glass production.

For businesses looking to stay competitive in the rapidly evolving glass industry, investing in automated CNC glass cutting lines is no longer just an option—it's a necessity. By embracing these cutting-edge technologies, manufacturers can not only improve their bottom line but also contribute to a more sustainable and innovative future for glass production.

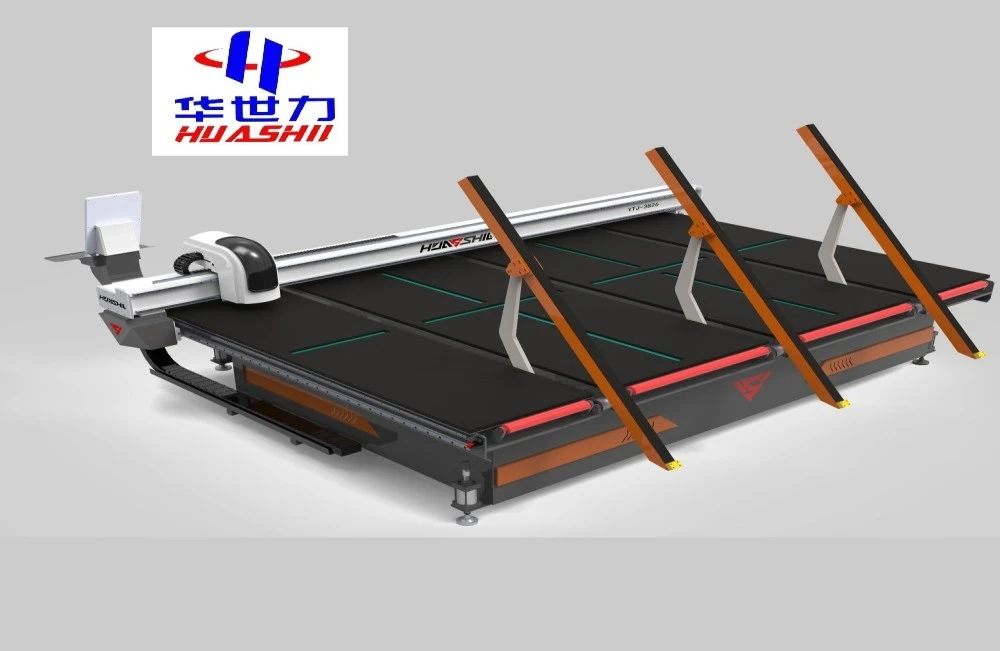

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges and opportunities presented by automation in the glass industry. Our team of experts is dedicated to providing cutting-edge CNC glass cutting solutions that meet the specific needs of our clients. With years of experience in R&D, manufacturing, and sales of automated mechanical equipment, we offer advanced techniques, stable quality, and excellent service that have made us a trusted partner for customers worldwide.

Ready to take your glass cutting operations to the next level? Contact us today at salescathy@sdhuashil.com to learn more about our customized CNC glass cutting lines and how we can help you achieve your production goals. Let's work together to shape the future of glass manufacturing!

References

1. Johnson, A. (2023). "The Evolution of CNC Technology in Glass Processing". Journal of Advanced Manufacturing Technologies, 45(2), 112-128.

2. Zhang, L., & Williams, K. (2022). "AI-Driven Optimization in Modern Glass Cutting Systems". International Journal of Automation and Smart Technology, 18(3), 287-301.

3. Patel, R. (2023). "Industry 4.0 and Its Impact on Glass Manufacturing". Glass Technology: European Journal of Glass Science and Technology Part A, 64(1), 1-15.

4. Müller, H., & Nakamura, S. (2022). "Sustainability in Automated Glass Production: A Comprehensive Review". Journal of Cleaner Production, 355, 131872.