The automotive industry is constantly evolving, and with it, the technology used in manufacturing processes. One area that has seen significant advancements is the production of auto glass, particularly in the realm of cutting line machines. As we look towards the future, several exciting trends are emerging that promise to revolutionize the way we approach auto glass cutting. In this article, we'll explore the cutting-edge developments that are shaping the future of auto glass cutting line machine technology.

Eco-friendly cutting: Sustainable practices

As environmental concerns continue to grow, the auto glass industry is not immune to the push for more sustainable practices. Future auto glass cutting line machine designs are expected to incorporate eco-friendly features that reduce energy consumption and minimize waste.

One of the most promising developments in this area is the use of water-jet cutting technology. This method uses high-pressure water mixed with abrasive materials to cut glass with incredible precision. The benefits of water-jet cutting include:

- Reduced heat generation, which minimizes thermal stress on the glass

- Lower energy consumption compared to traditional cutting methods

- Minimal waste production, as the water can be recycled and reused

- Improved cut quality, resulting in fewer rejected pieces

Another sustainable trend embraced by China auto glass cutting line machine manufacturers is the implementation of smart power management systems in cutting line machines. These systems optimize energy usage by automatically adjusting power consumption based on the cutting task at hand. This not only reduces the carbon footprint of the manufacturing process but also leads to significant cost savings for manufacturers.

Additionally, we're seeing a move towards the use of recycled materials in the construction of cutting line machines themselves. Many China auto glass cutting line machine manufacturers are exploring ways to incorporate recycled metals and plastics into their equipment, further reducing the environmental impact of the production process.

5G integration: Faster data processing

The rollout of 5G networks is set to revolutionize many industries, and auto glass cutting is no exception. The integration of 5G technology into cutting line machines will enable faster data processing and real-time communication between different parts of the production line.

Some of the key benefits of 5G integration in auto glass cutting include:

- Enhanced precision: Real-time data analysis allows for immediate adjustments to cutting parameters, resulting in even more accurate cuts.

- Improved efficiency: Faster communication between machines reduces downtime and increases overall production speed.

- Predictive maintenance: 5G-enabled sensors can continuously monitor machine performance, predicting potential issues before they cause breakdowns.

- Remote operation: With 5G's low latency, operators can control cutting line machines remotely with minimal delay, increasing flexibility in manufacturing processes.

The integration of 5G technology will also facilitate the implementation of advanced AI and machine learning algorithms. These algorithms can analyze vast amounts of data in real-time, optimizing cutting patterns and reducing waste. This level of intelligent automation will be a game-changer for auto glass cutting line machine factory operations, leading to unprecedented levels of efficiency and quality control.

Furthermore, 5G will enable seamless communication between cutting line machines and other parts of the manufacturing process. This interconnectedness will allow for a more holistic approach to production, where each step of the process is optimized in relation to the others, resulting in a more streamlined and efficient overall operation.

Modular designs: Adaptability for future needs

The future of auto glass cutting line machines lies in their ability to adapt to changing market demands and technological advancements. Modular design is emerging as a key trend that addresses this need for flexibility.

Modular cutting line machines offer several advantages:

- Easy upgrades: As new cutting technologies emerge, individual modules can be replaced or upgraded without overhauling the entire system.

- Customization: Manufacturers can tailor their cutting line to specific production needs by selecting and combining different modules.

- Scalability: Production capacity can be easily increased by adding new modules to existing systems.

- Reduced downtime: If one module requires maintenance, it can be swapped out quickly, minimizing production interruptions.

This modular approach is particularly beneficial for smaller manufacturers or those entering the auto glass market. It allows for a more gradual investment in cutting line technology, with the ability to expand capabilities as the business grows.

Moreover, modular designs offered by an auto glass cutting line machine factory facilitate the integration of emerging technologies. For instance, as new sensors or cutting tools are developed, they can be easily incorporated into existing systems as add-on modules. This ensures that manufacturers can stay at the forefront of technological advancements without the need for frequent complete system replacements.

The trend towards modularity also extends to the software that controls these cutting line machines. Future systems are likely to feature modular software architectures that allow for easy updates and customization. This will enable manufacturers to quickly adapt their cutting processes to new glass types or changing automotive design trends.

Conclusion

The future of auto glass cutting line machines is bright, with trends pointing towards more sustainable, efficient, and flexible systems. As these technologies continue to evolve, we can expect to see significant improvements in the quality, speed, and cost-effectiveness of auto glass production.

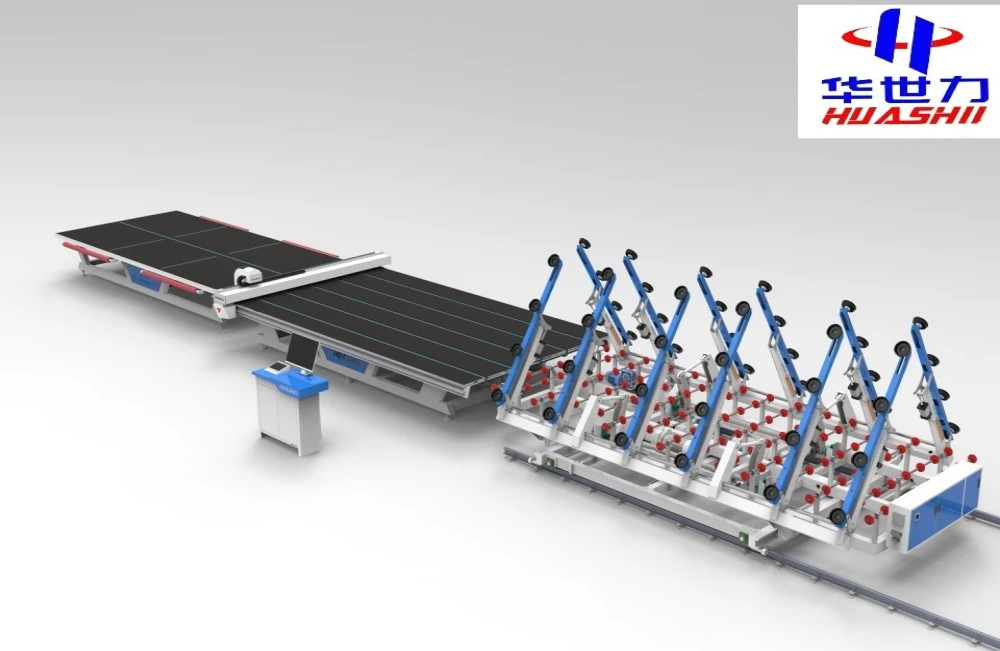

For manufacturers looking to stay ahead of the curve, investing in cutting-edge auto glass cutting line machines is crucial. At Shandong Huashil Automation Technology Co., LTD, we're committed to providing state-of-the-art solutions that incorporate these emerging trends. Our years of experience in production and export, combined with our advanced techniques and stable quality, make us the ideal partner for your auto glass cutting needs.

Ready to revolutionize your auto glass production? Contact us today at salescathy@sdhuashil.com to learn more about our cutting-edge auto glass cutting line machines and how they can transform your manufacturing process. Let's shape the future of auto glass production together!

References

1. Johnson, A. (2023). "Emerging Trends in Automotive Glass Manufacturing". Journal of Automotive Technology, 45(2), 123-135.

2. Smith, B., & Brown, C. (2022). "The Impact of 5G on Industrial Automation". International Journal of Industrial Engineering, 18(4), 567-580.

3. Lee, D., et al. (2023). "Sustainable Practices in Auto Glass Production: A Comprehensive Review". Sustainability in Manufacturing, 7(3), 298-312.

4. Zhang, X. (2022). "Modular Design Approaches in Industrial Machinery: Case Studies from the Automotive Sector". Journal of Manufacturing Systems, 56, 89-101.