Finding the correct automatic stone cutting machine can turn your granite processing activities from hard work into smooth production lines. Advanced CNC stone cutters make precise cuts, waste less material, and greatly increase production in fabrication operations all around the world. Modern stone cutting automation systems combine advanced control software with powerful cutting tools. This lets manufacturers tackle complicated projects with little or no human help.

Why Focus on Advanced Stone Processing Equipment?

The stone cutting industry is under a lot of pressure to speed up the time it takes to finish a job while still meeting high quality standards. When it comes to big architectural projects or complicated ornamental parts, traditional manual cutting methods have a hard time keeping up with modern production needs. Stone cutting technology has come a long way. Automated equipment can now treat a wide range of materials, such as granite, marble, and artificial stone, with amazing accuracy.

Advanced automation in granite cutting machines helps to eliminate the production problems that are common in traditional workshops. These methods reduce the chance of human error and make the most of materials, which has a direct effect on profits. Production directors like how new stone cutting tools fit right in with their current workflows without needing a lot of changes to the facilities.

Essential Selection Criteria for Stone Cutting Equipment

To choose the best stone cutting machine, you need to carefully consider many performance parameters. The most important thing is that machines are reliable, because downtime in manufacturing affects delivery times and customer happiness. Machines that process stone must work the same way on granite of different densities and thicknesses.

The total cost of ownership includes more than just the initial purchase price. It also includes installation, training, maintenance, and the availability of spare parts. An automatic stone cutting machine that comes with a full support network is a better long-term investment than cheap choices that just offer limited service. The amount of production must meet present needs and leave room for future growth.

Technical Specifications Matter

The quality of the final product and how many customers accept it depend on how precise the cutting is. Modern CNC stone cutters can cut to within 0.1mm, which lets fabricators meet strict architectural standards. The speed of cutting stone impacts the overall throughput. More modern systems can process more than one piece at a time.

Software Integration Capabilities

Modern stone cutting software works well with design programs, so you can easily import CAD files for automated cutting operations. This feature cuts down on development time and mistakes that happen when data is moved between systems.

Safety and Environmental Features

Modern stone cutting robotics incorporate advanced safety systems including emergency stops, protective barriers, and dust collection mechanisms. These features protect operators while maintaining compliance with international safety standards.

Top Automatic Stone Cutting Machines for 2025

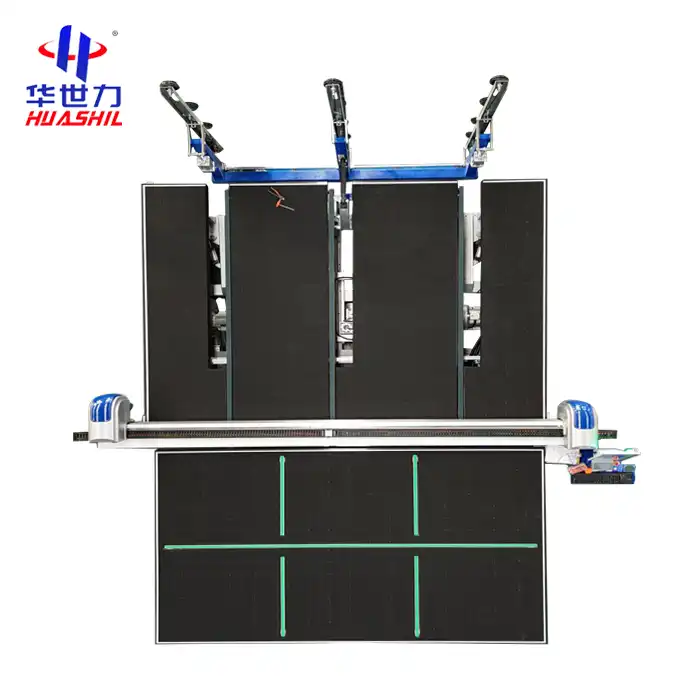

HUASHIL HSL-CNC2716 Advanced Stone Processing System

The HSL-CNC2716 represents cutting-edge stone cutting automation technology designed for high-volume production environments. This system handles materials up to 2700×1600mm, accommodating large granite slabs common in architectural applications. The machine processes cutting thickness ranging from 3-18mm, making it versatile for various project requirements.

Key technical advantages include:

- Eos-CNC control system providing intuitive operation and precise positioning

- Automatic pressure control system optimizing cutting force for different materials

- Advanced edge-finding technology ensuring accurate material positioning

- Air flotation system reducing material handling effort and preventing surface damage

- Multi-material capability including sintered stone, ceramic slabs, and tile cutting applications

The automatic pressure control feature adapts cutting parameters based on material density and thickness, preventing blade damage while maintaining optimal cutting speeds. This intelligent system reduces operator intervention while protecting valuable cutting tools.

Production facilities appreciate the air flotation system, which virtually eliminates manual lifting of heavy stone slabs. This feature significantly reduces workplace injuries while improving material handling efficiency. The automatic edge finding capability ensures consistent positioning accuracy, crucial for maintaining tight tolerances across production runs.

Professional CNC Bridge Cutting Systems

Bridge-style stone cutting machines excel in processing oversized granite slabs while maintaining exceptional precision. These systems feature robust gantry designs supporting heavy cutting heads without vibration or deflection. Advanced servo motor systems provide smooth, accurate movements across all axes.

Notable features include:

- Heavy-duty construction supporting continuous operation

- Multiple cutting head configurations for simultaneous operations

- Integrated water management systems preventing dust generation

- Programmable cutting patterns reducing setup time

- Remote monitoring capabilities for production oversight

These machines typically accommodate slabs exceeding 3000×2000mm, suitable for large curtain wall projects and architectural installations. Variable speed controls optimize cutting parameters for different granite types and thicknesses.

Compact Desktop Stone Cutting Solutions

Smaller fabrication shops benefit from compact stone processing machines designed for limited floor space. These systems deliver professional cutting quality while maintaining affordability for growing businesses. Desktop models typically handle materials up to 1200×800mm, perfect for countertop fabrication and decorative applications.

Advantages include:

- Lower initial investment costs

- Reduced facility requirements

- Simplified operation and maintenance

- Quick setup and changeover times

- Energy-efficient operation

Despite their compact size, these machines incorporate advanced stone cutting technology, including precision linear guides, variable speed controls, and automated tool changing systems. Many models feature modular designs allowing future upgrades as business needs evolve. An automatic stone cutting machine is a smart choice for businesses looking to combine efficiency with high-quality output.

Regional Market Analysis and Requirements

Different markets around the world have their own problems and chances when it comes to deploying stone cutting equipment. Manufacturers can choose the right machinery designs and support structures if they know what people in different areas like.

Southeast Asian Market Characteristics

Stone fabricators in Southeast Asia care most about having reliable equipment and being able to get technical support from people in their area. Because of the area's humid climate, corrosion prevention needs to be better and maintenance needs to happen more often. A lot of facilities are open for longer hours, which means they need strong stone cutting automation systems that can run all the time.

Local building codes stress earthquake resilience, which means that structural connections must be cut very precisely. For these strict requirements to be met while keeping prices affordable, stone cutting accuracy becomes very important.

Russian Federation Requirements

Russian stone processing plants generally work with very hard types of granite that need unique cutting tools and methods. Equipment must work well in tough winter circumstances and still be able to cut accurately. Having extra parts on hand nearby is important for keeping downtime to a minimum when transportation distances are long.

High-capacity stone slab cutters that can handle a lot of work quickly are in high demand because of big infrastructure projects. Automation makes it less necessary to hire qualified workers and makes production batches more consistent.

South American Preferences

South American markets like stone cutting solutions that are cheap and have flexible payment terms. Many facilities don't have a lot of technical people, so they need stone cutting software that is easy to use and training programs that cover everything. When service conditions are tough and maintenance resources are limited, the durability of equipment becomes very important.

Fabricators that make things for export need to meet international requirements for cutting quality while keeping production costs low. Machines that can work with a variety of stone types provide you more options when it comes to how you use them.

Middle Eastern Considerations

Middle Eastern stone processors work on high-end projects that need very high quality finishes and exact measurements. Desert locations have their own problems, such as dust getting in and temperatures changing very quickly. Climate-controlled cages and better filtration methods keep critical parts safe.

In this area, projects often have tight deadlines, so they need stone-cutting tools that are fast and easy to set up. Automated technologies help keep quality standards high while lowering the need for qualified workers from other countries.

Purchasing Recommendations and Key Considerations

Successful stone cutting equipment procurement requires careful evaluation of current production needs and future growth projections. Start by analyzing existing bottlenecks and identifying specific performance improvements needed. Document current production volumes, typical material dimensions, and quality requirements to guide equipment selection.

Consider the total cost of ownership, including installation, training, maintenance contracts, and spare parts inventory. Reputable stone cutting equipment manufacturers provide detailed cost projections covering typical operational scenarios. When calculating return on investment, factor in productivity improvements and labor cost reductions associated with an automatic stone cutting machine.

Evaluate supplier credentials including manufacturing experience, installation expertise, and ongoing technical support capabilities. Request customer references from similar applications and arrange facility visits to observe equipment performance firsthand. Comprehensive warranty coverage and spare parts availability significantly impact long-term operational costs.

Plan implementation carefully to minimize production disruption during installation and commissioning. Coordinate with suppliers to schedule installation during planned maintenance periods or facility expansions. Ensure adequate operator training before full production implementation.

Industry Trends and Future Outlook

Stone cutting technology continues advancing toward greater automation and integration capabilities. Artificial intelligence enhances cutting optimization while reducing material waste. Remote monitoring systems enable predictive maintenance reducing unexpected downtime. Industry consolidation drives demand for higher productivity equipment capable of handling diverse material types efficiently. Environmental regulations promote water recycling systems and dust reduction technologies in modern stone processing facilities.

Conclusion

Selecting the optimal automatic stone cutting machine requires balancing performance capabilities with operational requirements and budget constraints. Modern CNC stone cutters like the HUASHIL HSL-CNC2716 demonstrate how advanced automation transforms traditional stone processing into efficient, profitable operations. Success depends on choosing equipment that matches your specific applications while providing room for future growth. Regional market characteristics influence equipment requirements, making local support and service capabilities essential considerations. Investment in quality stone cutting technology pays dividends through improved productivity, enhanced product quality, and reduced operational costs over the equipment lifecycle.

Frequently Asked Questions

Q1: What cutting thickness range should I expect from modern automatic stone cutting machines?

A: Contemporary stone cutting systems typically handle materials from 3-50mm thickness depending on machine configuration. The HUASHIL HSL-CNC2716 processes 3-18mm thickness, ideal for most architectural and decorative applications. Specialized heavy-duty systems accommodate thicker materials for structural components.

Q2: How do I determine the appropriate cutting table size for my operations?

A: Analyze your typical material dimensions and consider future project requirements. Standard granite slabs measure 3000×2000mm, but finished pieces are often smaller. Choose equipment accommodating your largest regular materials while considering available floor space and material handling capabilities.

Q3: What maintenance requirements should I expect with automated stone cutting equipment?

A: Regular maintenance includes blade inspection and replacement, lubrication of moving components, water system cleaning, and control system updates. Most manufacturers recommend daily cleaning, weekly component checks, and monthly comprehensive inspections. Proper maintenance extends equipment life while maintaining cutting quality.

Partner with Leading Stone Cutting Technology Specialists

HUASHIL delivers proven stone cutting automation solutions backed by comprehensive technical support and competitive pricing. Our HSL-CNC2716 automatic stone cutting machine manufacturer expertise spans over a decade serving fabricators worldwide. Advanced control systems, robust construction, and innovative features like automatic pressure control set our equipment apart from conventional alternatives. Experience the difference precision engineering makes in your production efficiency and product quality. Contact us at salescathy@sdhuashil.com for detailed specifications and customized recommendations.

References

1. Stone Industry Magazine. "Automation Trends in Stone Processing: A Comprehensive Analysis of Modern Cutting Technologies." Industrial Publishing Group, 2023.

2. Martinez, Roberto and Chen, Wei. "Precision Cutting Systems for Architectural Stone: Performance Evaluation and Selection Criteria." Journal of Manufacturing Technology, Vol. 45, 2023.

3. International Stone Trade Association. "Global Market Report: Automated Stone Processing Equipment Demand and Regional Trends." ISTA Publications, 2023.

4. Thompson, Sarah. "CNC Stone Cutting: Advanced Control Systems and Production Optimization Strategies." Stone Processing Technology Review, Issue 3, 2023.

5. European Stone Processing Council. "Safety and Environmental Standards for Automated Stone Cutting Equipment." ESPC Technical Guidelines, 2023.

6. Anderson, Michael and Kumar, Pradeep. "Economic Analysis of Stone Processing Automation: ROI Calculations and Implementation Strategies." Manufacturing Economics Quarterly, Vol. 28, 2023.