To work with large format tiles, you need the correct tools, accuracy, and speed. A large tile cutting machine is the most important tool for professional tile installation since it makes difficult jobs easier. Modern builders are getting more and more requests for large ceramic slabs, sintered stone panels, and architectural tiles that typical cutting machines just can't handle well. This complete guide covers everything contractors need to know about choosing, using, and getting the most out of professional-grade cutting tools for big projects.

Understanding Large Format Tile Cutting Challenges

Large size tiles come with their own set of problems that make the difference between amateur and professional installations. These huge panels, which are often longer than 1200mm, need particular tools and techniques to handle and cut them accurately. The size and weight of these materials make it hard for traditional manual tile cutters to make consistent cuts, which can waste materials and create safety risks.

When you cut bigger tiles, the way the weight is spread out can induce stress areas that can make them shatter. Professional contractors know that buying the right tools keeps them from making expensive mistakes and keeps their clients happy. These large format materials are becoming more and more important for modern construction projects since they look better and have fewer grout lines.

When working with costly materials like sintered stone or big ceramic slabs, accuracy is very important. One mistake can squander hundreds of dollars' worth of materials and postpone the job. Good cutting tools get rid of these dangers and make work more productive overall.

Types of Large Format Cutting Equipment

When it comes to cutting equipment for big format applications, professional contractors have a lot of choices. Each type has its own benefits, depending on the project's objectives, the sorts of materials being used, and the amount of production needed. Electric tile cutting machines are great for tough jobs because they deliver power consistently and allow for precise control. They can cut through porcelain, ceramic, and natural stone just as well as other materials. Advanced models have water cooling systems that keep the machine from becoming too hot and make less dust.

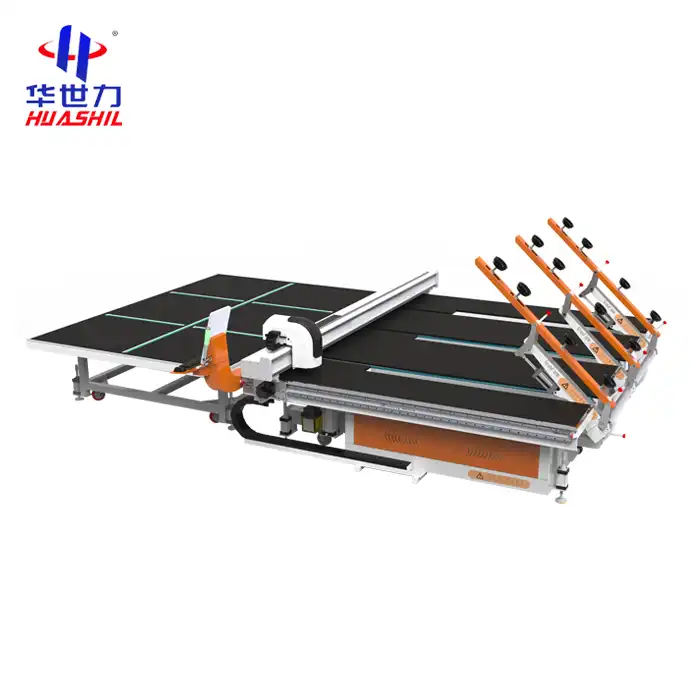

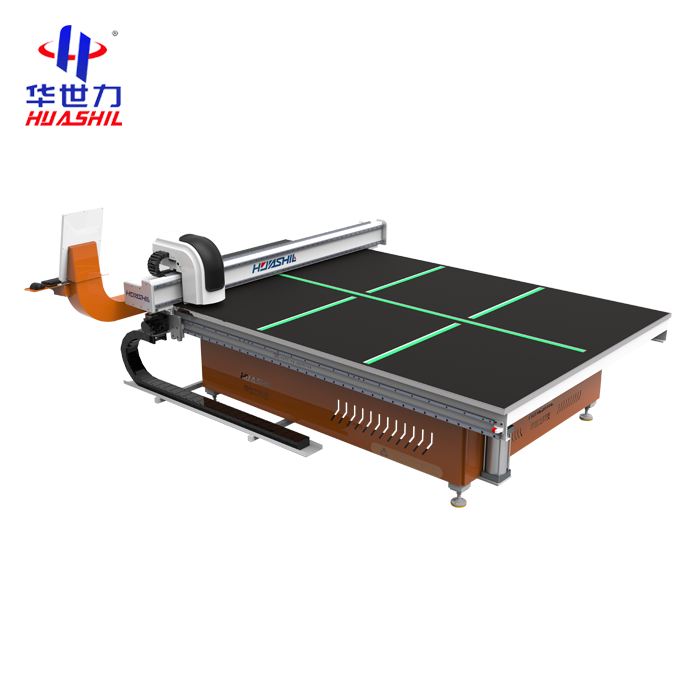

The HSL-CNC2716 model is an example of a CNC-controlled cutting system that is the best in terms of precision cutting. It can handle materials up to 2700x1600mm and can cut glass that is 3 to 18mm thick. These automated systems have pressure control, edge-finding features, and air flotation systems that make it easy to move materials around. Additionally, large tile cutting machines are essential for handling larger tiles and ensuring accurate cuts. Wet tile cutters are also still necessary for jobs that need smooth, chip-free edges. The constant flow of water keeps the blade from overheating and washes away dirt that could make cutting less accurate. Professional-grade wet cutters can use several sorts of blades that are best for cutting different types of materials.

Key Features to Consider When Purchasing

Choosing the right cutting tools requires careful consideration of certain features that affect performance, dependability, and long-term value. This is because knowing these features helps contractors make smart buying choices that help them reach their business goals. Cutting capacity is the largest size of material that the machine can handle. When looking at capacity parameters, skilled contractors should think about both the needs of the current project and their plans for future growth. Machines with bigger cutting areas are more flexible, but they need more space to function and cost more to buy.

Precision control systems make sure that the cut quality is the same no matter what the material or thickness is. Advanced machines even have automatic pressure adjustment that changes the cutting force based on the material's density and thickness. This feature keeps the cutting speed at its best while stopping cracks from forming. Blade compatibility also influences performance and running costs. Machines that can use standard diamond tile blades let you choose the best cutting tools for different materials. Good machines can handle blades of different sizes and mounting styles.

In addition, safety features like emergency stops, blade guards, and material hold-downs are important for keeping operators safe and lowering liability worries because they stop accidents from happening during operation. Professional-grade tools have full safety mechanisms that satisfy industry standards.

Material-Specific Cutting Techniques

To get the best results, contractors need to know how to cut different types of tile. This helps them get the most out of their tools while making the least amount of waste and errors. When cutting porcelain tile, you need sharp diamond blades and a consistent feed rate to avoid chipping. This is because porcelain is very dense and needs steady pressure to make cuts instead of forcing them. To keep the blades sharp and stop the material from getting too hot, water cooling is necessary.

On the other hand, cutting ceramic tile usually lets you feed the material in faster since it is softer. However, glazed surfaces need extra care to avoid chipping, and commencing cuts from the glazed side usually give cleaner results. Sintered stone applications need distinct cutting parameters because of the way the material is made. This means that the blades and cutting speeds need to be set up to work best with the material's unique qualities. For these precise uses, the HSL-CNC2716's ability to locate edges automatically is quite useful.

Additionally, large tile cutting machines are particularly effective when working with natural stone, as they provide the necessary support and precision for larger pieces. Cutting natural stone is very diverse depending on the type of stone and the structure of its grain. For example, marble needs different tools than granite or travertine. For operators to choose the right cutting parameters for each job, they need to know how materials work.

Maintenance and Blade Selection

Regular maintenance schedules keep machines running smoothly and cutting accurately over time, while proper maintenance makes equipment last longer and keeps cutting performance consistent. Cleaning away waste from cutting regions, testing water flow systems, and verifying the condition of blades are all part of daily maintenance. These easy chores keep buildup from happening that could impact cutting precision or cause blades to wear out too quickly.

Choosing the right blade has a big effect on cutting performance and operating costs. Diamond tile blades made for certain materials cut the fastest and last the longest. For cutting hard materials smoothly, continuous rim blades work well. For general-purpose tasks, segmented blades work well. You need to check your blades often to find wear patterns that show when they need to be adjusted. Dull blades make cutting forces and heat rise, which can damage both the equipment and the materials. To keep cutting quality high and avoid damage to equipment, it's important to change blades before they get too worn out.

Also, lubrication regimens for mechanical parts make sure they work smoothly and don't break down too soon. Following the manufacturer's recommendations for the types of lubricants to use and how often to change them preserves your investment in your equipment.

Safety Protocols and Best Practices

Professional tile cutting operations need strict safety rules that keep workers safe while still getting the job done. Knowing and following these rules lowers the risk of accidents and makes sure that the company follows all safety rules at work. When cutting tiles, there are many risks that can be avoided with the right personal protective equipment (PPE), such as safety glasses, hearing protection, and dust masks. To safeguard workers and lower the risk of liability, it is important to set and enforce PPE regulations.

When working with large format tiles, including those processed by a large tile cutting machine, it is very important to follow the right methods for handling materials. These hefty panels need to be lifted correctly and by the appropriate number of people to avoid injury. Using material handling tools like suction cups or mechanical lifts makes it easier on workers' bodies. Also, keeping your workspace organized is important for both safety and productivity. Maintaining clear pathways, proper lighting, and organized storage reduces risks and helps operations run smoothly. All staff should be able to easily see and review emergency procedures on a frequent basis.

Also, training on how to use equipment makes sure that workers know how to cut correctly and follow safety rules. Regular training updates keep workers up to date on best practices and changes to the equipment. Written records of training show that the company cares about following the rules and keeping the workplace safe.

Cost Considerations and ROI Analysis

Before buying professional cutting tools, you need to do a lot of financial analysis to make sure you get a good return on your money. Contractors may make smart buying decisions that help their businesses flourish if they know both direct and indirect expenses.

The initial expenses of equipment might be very different depending on how well it works and how automated it is. Basic manual cutters work well for little jobs, but automated systems like the HSL-CNC2716 are worth the extra money since they are more productive and accurate. Contractors should look at the costs of equipment in relation to the amount of work they expect to do and the profit margins they expect to make.

Operating costs include things like blades, utilities, and maintenance materials that need to be used up. Quality equipment usually has lower long-term running expenses since it works better and needs less maintenance. Energy-efficient designs help the environment and save utility bills at the same time.

Better productivity from professional tools has a direct effect on profits. Faster cutting speeds, less waste, and better precision all mean higher profit margins and happier customers. These things frequently make it worth it to spend more on equipment up front.

Contractors with little money can buy sophisticated tools thanks to financing alternatives. Instead of making big purchases all at once, you can use equipment finance, leasing, or payment plans from the manufacturer. Comparing the expenses of financing with the increases in productivity helps you figure out the best ways to buy things.

Technology Advances in Tile Cutting

Cutting technology keeps becoming better, giving contractors new tools and better performance. Keeping up with new technologies helps contractors stay ahead of the competition and make their businesses run more smoothly.

Computer numerical control systems make tile cutting operations more accurate and repeatable than ever before. These solutions get rid of mistakes made by people and make it possible to cut in ways that manual operations can't. The Eos-cnc control system is a great example of these improvements because it is easy to program and works well.

Automated material handling enhances safety and reduces physical strain. Air flotation devices hold heavy materials in place while they are being cut, which minimizes operator fatigue and improves the quality of the cut. These features are particularly beneficial in environments where large tile cutting machines are used for high-volume production.

Smart monitoring lets you see how your cutting parameters and equipment are doing in real time. These technologies warn operators about possible problems before they happen, which cuts down on downtime and maintenance expenses. Predictive maintenance features improve service schedules by looking at how the equipment is really used.

Integration capabilities let cutting systems talk to other production equipment and management systems. This connection makes it possible to automate activities and collect data, which makes everything run more smoothly and helps with quality control.

Conclusion

Contractors who operate with large format materials need to buy professional tile cutting tools. The appropriate tools help businesses develop by making work more efficient, accurate, and waste-free. Modern cutting systems include enhanced features that make things easier while yet meeting the highest quality standards.

Contractors may get the most out of their equipment investments by knowing what materials they need, how to keep them safe, and how to keep them in good shape. Technology keeps becoming better, giving us new tools that help us meet the changing needs of the market. Contractors that buy good tools and get the right training are setting themselves up for long-term success in the competitive tile installation industry.

Partner with HUASHIL for Professional Large Tile Cutting Solutions

HUASHIL stands as a leading large tile cutting machine manufacturer, delivering precision-engineered solutions that meet demanding contractor requirements. Our advanced HSL-CNC2716 system combines cutting-edge technology with proven reliability for sintered stone, ceramic slabs, and large format tile applications. With comprehensive after-sales support and competitive pricing, we provide the complete package contractors need to succeed. Ready to upgrade your cutting capabilities? Contact us at salescathy@sdhuashil.com today.

References

1. Smith, J. (2023). "Advanced Ceramic Processing Techniques for Large Format Applications." Industrial Ceramics Quarterly, Vol. 45, No. 3, pp. 78-92.

2. Thompson, R. & Miller, K. (2022). "Safety Protocols in Modern Tile Cutting Operations: A Comprehensive Analysis." Construction Safety Journal, Vol. 28, No. 7, pp. 134-148.

3. Anderson, M. (2023). "Economic Impact of Automated Cutting Systems in Commercial Construction." Building Technology Review, Vol. 67, No. 2, pp. 45-59.

4. Chen, L. (2022). "Material Properties and Cutting Optimization for Sintered Stone Products." Materials Engineering Today, Vol. 39, No. 5, pp. 112-126.

5. Rodriguez, P. (2023). "Precision Control Systems in Industrial Tile Processing Equipment." Automation in Manufacturing, Vol. 52, No. 4, pp. 203-217.

6. Williams, D. (2022). "Maintenance Strategies for High-Performance Cutting Equipment." Industrial Maintenance Monthly, Vol. 31, No. 9, pp. 67-81.