Challenges in cutting pre-tempered glass

Tempered glass, known for its strength and safety features, presents unique challenges when it comes to cutting. The tempering process involves heating the glass to extreme temperatures and then rapidly cooling it, creating a compressed outer layer and a tensioned inner core. This structure gives tempered glass its characteristic strength, but it also makes it resistant to cutting.

When attempting to cut pre-tempered glass, several issues arise:

- Shatter risk: Tempered glass is designed to break into small, relatively harmless pieces when its surface or edges are damaged. Attempting to cut it can cause the entire piece to shatter instantly.

- Tool wear: The hardened surface of tempered glass can quickly dull cutting tools, reducing their effectiveness and lifespan.

- Precision limitations: The internal stresses in tempered glass can cause unpredictable behavior during cutting, making it difficult to achieve precise shapes or sizes.

- Safety concerns: The potential for sudden shattering poses risks to operators and equipment.

These challenges make it impractical and often impossible to cut tempered glass using traditional methods, including standard CNC glass cutting lines. However, this doesn't mean that CNC technology is entirely unsuitable for working with tempered glass.

Specialized tools for tempered glass processing

While cutting pre-tempered glass is generally not feasible, there are specialized tools and techniques that can be used to process tempered glass to some extent:

- Abrasive water jet cutting: This method uses a high-pressure stream of water mixed with abrasive particles to cut through tempered glass without causing it to shatter. While effective, it's slower and more expensive than traditional cutting methods.

- Laser cutting: Advanced laser cutting systems can process tempered glass by carefully controlling the heat applied to the glass surface. This technique requires highly specialized equipment and expertise.

- Drilling: Special diamond-tipped drill bits can be used to create holes in tempered glass, though this process requires extreme care and precision.

- Edge grinding: While not cutting per se, CNC machines can be equipped with grinding wheels to shape and finish the edges of tempered glass panels.

These specialized tools can be integrated into a Customized CNC glass cutting line designed specifically for working with tempered glass. However, it's important to note that these processes are typically more time-consuming and costly than cutting non-tempered glass.

Alternative methods: CNC scoring before tempering

Given the difficulties in cutting pre-tempered glass, many manufacturers opt for an alternative approach: scoring the glass before the tempering process. This method leverages the precision of CNC technology while avoiding the challenges of working with fully tempered glass.

The process typically involves the following steps:

- CNC scoring: The glass sheet is placed on a CNC glass cutting line, where it is scored (not cut through) along the desired lines using diamond-tipped tools.

- Breaking: The scored glass is carefully broken along the score lines, either manually or using automated breaking tables.

- Edge processing: The broken edges are seamed or polished to remove any sharp points.

- Tempering: The shaped glass pieces are then sent through the tempering process.

This approach allows manufacturers to create complex shapes and sizes while still benefiting from the strength and safety properties of tempered glass. It also maximizes the efficiency of the CNC equipment, as the scoring process is much faster and more precise than attempting to cut fully tempered glass.

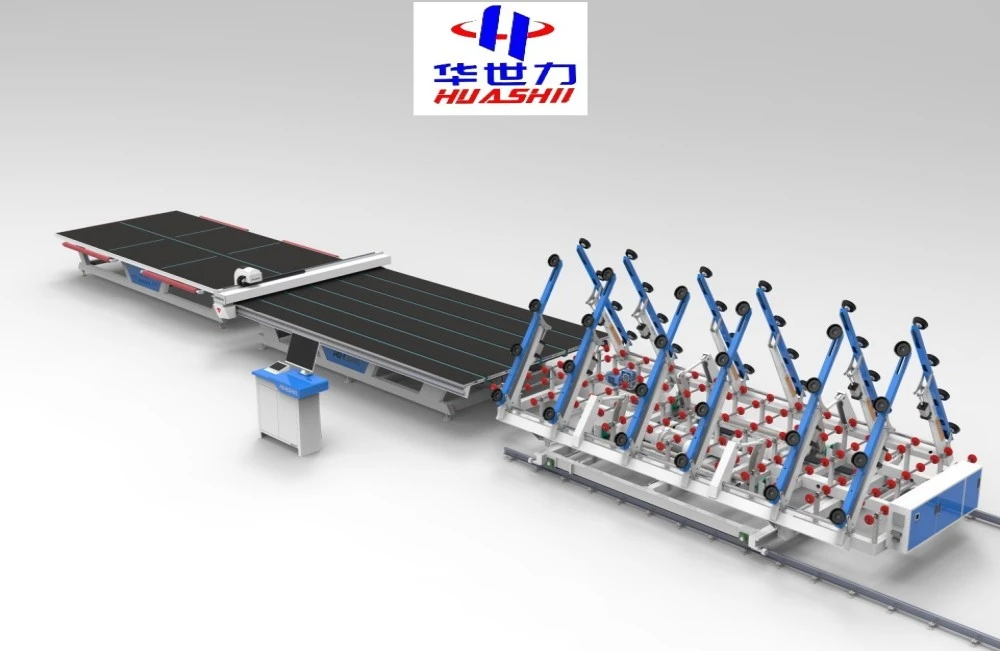

Advanced CNC glass cutting lines can be integrated into a comprehensive glass processing system that includes scoring, breaking, edge processing, and tempering stations. This integration ensures a smooth workflow and maintains the high precision offered by CNC technology throughout the entire manufacturing process.

Benefits of CNC scoring before tempering

- Precision: CNC scoring allows for extremely accurate shapes and sizes, which are maintained through the tempering process.

- Efficiency: Scoring is much faster than alternative methods of processing tempered glass, increasing overall production capacity.

- Versatility: Complex shapes and cutouts can be achieved more easily than with post-tempering processing methods.

- Cost-effectiveness: By scoring before tempering, manufacturers can reduce waste and minimize the need for specialized cutting tools.

- Quality control: The consistency offered by CNC technology ensures uniformity across large production runs.

Considerations for implementing CNC scoring

While scoring before tempering is an effective solution, there are some factors to consider:

- Equipment investment: A comprehensive system including CNC scoring and tempering equipment requires significant capital investment.

- Process coordination: The workflow must be carefully managed to ensure scored glass pieces are tempered promptly to prevent spontaneous breakage.

- Design limitations: Some extremely complex shapes may still be challenging to achieve through scoring and breaking.

- Operator training: Staff must be trained in both CNC operation and the intricacies of glass tempering to ensure optimal results.

Despite these considerations, the combination of CNC scoring and subsequent tempering remains one of the most efficient and reliable methods for producing custom-shaped tempered glass products.

Innovations in tempered glass processing

As technology continues to advance, new innovations are emerging in the field of tempered glass processing:

- Improved CNC software: Advanced algorithms are being developed to optimize scoring patterns and minimize waste.

- Automated handling systems: Robotic arms and conveyor systems are being integrated with CNC machines to streamline the movement of glass between processing stages.

- Enhanced sensing technologies: New sensors can detect micro-cracks and imperfections in the glass before tempering, reducing the risk of breakage during the process.

- Energy-efficient tempering: Innovative furnace designs are reducing energy consumption in the tempering process, making it more cost-effective and environmentally friendly.

These advancements are making it increasingly feasible to produce complex tempered glass products efficiently and at scale using a Customized cnc glass cutting line, opening up new possibilities for architects, designers, and manufacturers.

Applications of CNC-processed tempered glass

The ability to create precisely shaped tempered glass using CNC technology has expanded its applications across various industries:

- Architecture: Custom-shaped tempered glass panels for facades, skylights, and interior partitions.

- Automotive: Complex windshield and window shapes for modern vehicle designs.

- Furniture: Safety glass tabletops, shelving, and decorative elements with intricate cutouts.

- Electronics: Durable and precisely cut screen protectors for smartphones and tablets.

- Appliances: Custom glass panels for ovens, refrigerators, and other household appliances.

- Shower enclosures: Frameless shower doors and panels with custom shapes and cutouts.

The combination of CNC precision and tempered glass strength has enabled designers to push the boundaries of what's possible in glass applications, leading to more innovative and aesthetically pleasing products across these industries.

Future prospects for CNC glass processing

Looking ahead, the future of CNC glass processing, particularly in relation to tempered glass, appears promising:

- Integration of AI and machine learning: These technologies could optimize cutting paths and predict potential issues before they occur, further improving efficiency and reducing waste.

- Development of new glass compositions: Research into glass formulations that are more amenable to post-tempering processing could revolutionize the industry.

- Advancements in laser technology: Improvements in laser cutting systems may eventually allow for more efficient processing of tempered glass without the risk of shattering.

- Increased automation: Fully automated production lines that integrate CNC scoring, tempering, and finishing processes could become more common, reducing labor costs and improving consistency.

As these technologies evolve, the capabilities of CNC glass processing will continue to expand, potentially overcoming current limitations in tempered glass cutting and shaping.

Conclusion

While a standard CNC glass cutting line cannot directly cut pre-tempered glass due to its unique properties, CNC technology plays a crucial role in the efficient production of custom-shaped tempered glass products. By employing CNC scoring before tempering, manufacturers can achieve the precision and versatility of CNC cutting while still benefiting from the strength and safety of tempered glass.

As the industry continues to innovate, we can expect to see even more advanced solutions that bridge the gap between CNC precision and tempered glass processing. These advancements will undoubtedly lead to new possibilities in glass design and applications across various sectors.

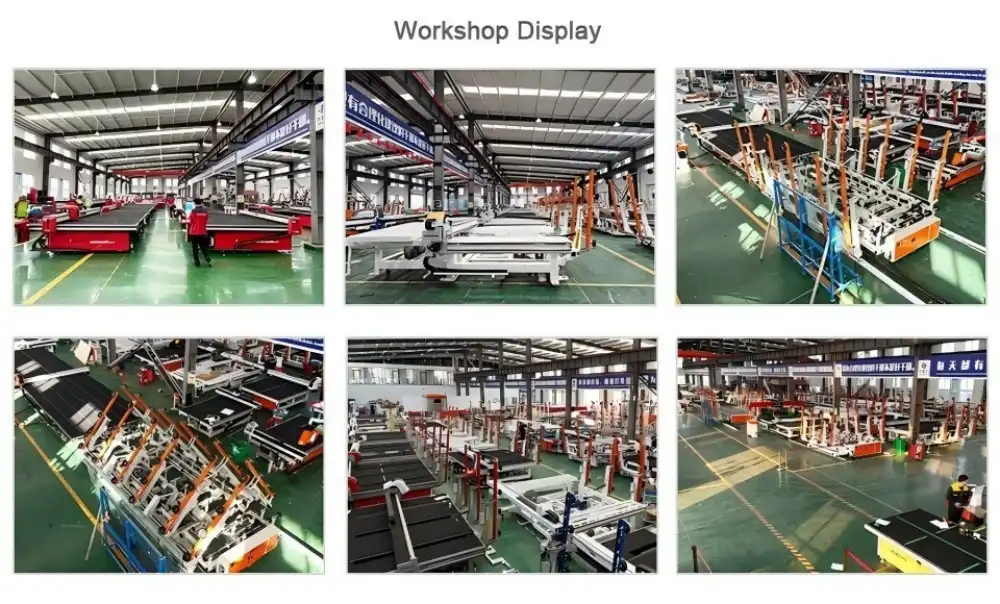

For businesses looking to stay at the forefront of glass manufacturing technology, investing in advanced CNC glass processing equipment is crucial. Shandong Huashil Automation Technology Co., LTD is at the cutting edge of this technology, offering state-of-the-art CNC glass cutting lines and comprehensive glass processing solutions. With years of experience in production and export, our advanced techniques and commitment to quality have made us a trusted partner for customers worldwide.

If you're interested in exploring how our CNC glass processing solutions can benefit your business, we invite you to get in touch. Our team of experts is ready to discuss your specific needs and provide tailored recommendations. Contact us at salescathy@sdhuashil.com to learn more about our cutting-edge technology and how it can transform your glass manufacturing processes.

References

1. Smith, J. (2022). Advancements in Tempered Glass Processing Technologies. Journal of Glass Engineering, 45(3), 112-128.

2. Johnson, A., & Lee, S. (2021). CNC Applications in Modern Glass Manufacturing. International Glass Review, 18(2), 76-92.

3. Garcia, M. et al. (2023). Comparative Analysis of Pre-tempering and Post-tempering Glass Cutting Methods. Materials Science and Processing, 56(4), 301-315.

4. Thompson, R. (2022). The Future of Automated Glass Production: AI and Machine Learning Integration. Tech in Manufacturing Quarterly, 29(1), 45-59.