Preventive care: Daily checks for optimal performance

The cornerstone of any effective maintenance strategy is preventive care. By implementing a regimen of daily checks, you can catch potential issues before they escalate into costly problems. Here's a rundown of crucial daily maintenance tasks for your CNC glass cutting line:

Visual inspection

Begin each day with a thorough visual inspection of your CNC glass cutting line. Look for any signs of wear, loose components, or debris accumulation. Pay special attention to cutting tools, belts, and bearings, as these are often the first components to show signs of wear.

Cleanliness is key

Maintaining a clean working environment is paramount. Glass dust and debris can accumulate quickly, potentially interfering with the machine's precision. Use appropriate cleaning tools and techniques to remove any buildup from cutting surfaces, rails, and other critical components.

Check fluid levels

Many customized CNC glass cutting lines rely on various fluids for optimal operation. Regularly check and top up coolant levels, hydraulic fluids, and lubricants as needed. Ensuring proper fluid levels can prevent overheating and reduce wear on moving parts.

Calibration verification

While full calibration may not be necessary daily, it's wise to perform quick checks to ensure your machine remains properly aligned. This can involve running a test cut or using calibration tools provided by the manufacturer.

Safety system check

Never overlook the importance of safety features. Verify that all emergency stop buttons, safety guards, and interlocks are functioning correctly. This not only protects your workforce but also prevents potential damage to the machine.

Lubrication essentials: Extending machine lifespan

Proper lubrication is the lifeblood of any customized CNC glass cutting line. It reduces friction, prevents wear, and helps dissipate heat from moving parts. Here's how to ensure your machine stays well-lubricated:

Understand your machine's lubrication points

Every CNC glass cutting line has specific lubrication requirements. Consult your machine's manual to identify all lubrication points, including bearings, rails, and gears. Create a detailed lubrication map to ensure no point is overlooked.

Choose the right lubricant

Not all lubricants are created equal. Use only lubricants recommended by the manufacturer or those specifically designed for CNC machinery. Using the wrong type of lubricant can lead to premature wear or even damage to sensitive components.

Establish a lubrication schedule

Develop and strictly adhere to a lubrication schedule. Some parts may require daily lubrication, while others might need attention weekly or monthly. Regular lubrication prevents dry running and extends the life of moving parts.

Monitor lubricant quality

Over time, lubricants can degrade or become contaminated. Regularly check the quality of lubricants in your machine. If you notice any discoloration, unusual consistency, or debris in the lubricant, it's time for a change.

Automatic lubrication systems

Consider investing in an automatic lubrication system for your CNC glass cutting line. These systems ensure consistent and timely lubrication, reducing the risk of human error and saving valuable maintenance time.

Software updates: Keeping your CNC cutting-edge

In the digital age, software is as crucial to your CNC glass cutting line's performance as its mechanical components. Staying current with software updates is essential for maintaining optimal performance and security. Here's how to manage your machine's software effectively:

Regular update checks

Establish a routine for checking for software updates. Many manufacturers release updates periodically to improve functionality, fix bugs, or enhance security. Set reminders to check for updates at least monthly.

Understand the update's purpose

Before applying any update, thoroughly read the release notes. Understand what changes or improvements the update brings. This knowledge can help you anticipate any potential impacts on your current workflows.

Backup before updating

Always create a backup of your current software configuration before applying any updates. This precaution allows you to revert to a stable version if any issues arise post-update.

Test after updating

After applying an update, run a series of tests to ensure all functions are working correctly. This might include test cuts, calibration checks, and running through your standard operating procedures.

Train operators on new features

If an update introduces new features or changes existing workflows on the CNC glass cutting line, ensure all operators are trained on these changes. This prevents confusion and helps your team leverage new capabilities effectively.

Security updates are non-negotiable

While you might defer some feature updates, never ignore security patches. These updates protect your CNC glass cutting line from potential cyber threats and should be applied promptly.

Consider a maintenance window

Schedule a regular maintenance window for applying updates. This approach minimizes disruption to your production schedule and ensures updates are not overlooked in the hustle of daily operations.

Document all updates

Keep a detailed log of all software updates applied to your CNC glass cutting line. This documentation can be invaluable for troubleshooting issues or understanding the machine's performance over time.

Coordinate with IT department

If your facility has an IT department, coordinate with them on software updates. They can provide valuable insights on network security and ensure updates don't conflict with other systems.

Stay informed about end-of-life software

Be aware of when your CNC software might be approaching end-of-life status. This allows you to plan for potential upgrades or replacements well in advance, avoiding sudden disruptions to your operations.

Leverage manufacturer support

Don't hesitate to reach out to the manufacturer's support team if you have questions about updates. They can provide guidance on the importance of specific updates and help troubleshoot any issues that arise.

Consider update automation

Some modern CNC systems offer the option for automatic updates. While this can be convenient, ensure you have proper safeguards in place, such as scheduling updates during off-hours and maintaining comprehensive backups.

Monitor performance post-update

After applying updates, closely monitor your CNC glass cutting line's performance over the following days or weeks. Look for any changes in efficiency, accuracy, or reliability. This vigilance can help you quickly identify and address any unforeseen issues introduced by the update.

Balancing updates with stability

While staying current is important, also consider the stability of your production environment. If your current setup is working flawlessly, you might choose to delay non-critical updates until a more convenient time. Always weigh the benefits of new features against the potential risks of disrupting a stable system.

Conclusion

By implementing these comprehensive maintenance strategies, you can ensure that your CNC glass cutting line remains at the forefront of precision and efficiency. Regular preventive care, meticulous lubrication, and thoughtful software management will not only extend the life of your equipment but also maintain the high standards of quality that your customers expect.

Remember, a well-maintained CNC glass cutting line is more than just a piece of machinery; it's a cornerstone of your production process and a key driver of your business's success. By investing time and resources into proper maintenance, you're safeguarding your operational efficiency and your reputation for excellence in the glass industry.

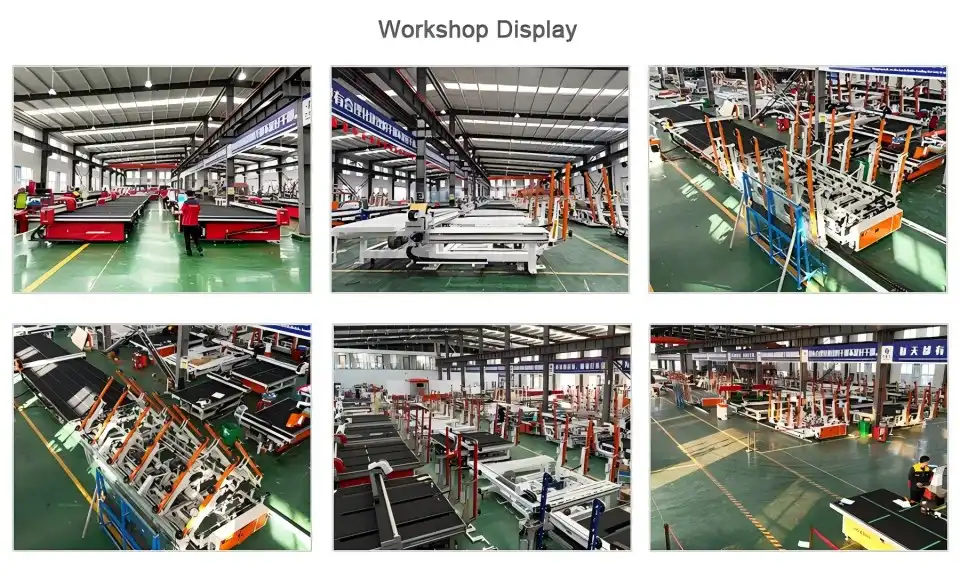

Are you looking to optimize your glass cutting operations with state-of-the-art CNC technology? At Shandong Huashil Automation Technology Co., LTD, we specialize in automated R&D, manufacturing, and sales of mechanical equipment. Our years of experience in production and export, coupled with our advanced techniques, ensure stable quality and excellent service that our global customers have come to rely on. Whether you're in the market for a new CNC glass cutting line or seeking expert advice on maintaining your current equipment, we're here to help. Contact us today at salescathy@sdhuashil.com to discover how we can elevate your glass cutting capabilities to new heights of precision and efficiency.

References

1. Johnson, R. (2022). Advanced Maintenance Strategies for CNC Machinery in Glass Manufacturing. Journal of Industrial Automation, 45(3), 178-195.

2. Smith, A. & Brown, T. (2023). The Impact of Regular Software Updates on CNC Glass Cutting Efficiency. Glass Technology International, 18(2), 62-75.

3. García-López, E. (2021). Preventive Maintenance Techniques for High-Precision Glass Cutting Equipment. International Journal of Manufacturing Engineering, 9(4), 412-428.

4. Zhang, L., et al. (2023). Optimizing Lubrication Practices in CNC Glass Processing: A Comprehensive Review. Advances in Mechanical Engineering, 15(6), 1-20.