In the rapidly evolving world of glass processing technology, manufacturers and fabricators constantly seek efficient solutions for cutting glass sheets of various sizes. The question of whether a small glass cutting machine can effectively handle large sheets of glass is increasingly important for industries ranging from construction and interior design to automotive and electronics manufacturing. This comprehensive exploration delves into the capabilities, limitations, and innovative approaches of small glass cutting machines when confronting the challenge of large glass sheets.

Can Small Glass Cutting Machines Handle Large Sheet Dimensions?

What Are the Technical Limitations of Small Glass Cutting Machines?

Advanced precision plays a crucial role in understanding the potential of small glass cutting machines when addressing large sheet requirements. Modern small glass cutting machines have undergone significant technological transformations that challenge traditional size constraints. Manufacturers have developed sophisticated mechanisms that extend the operational capabilities of compact equipment, enabling them to process substantially larger glass sheets than previously considered possible.

The core challenge lies in the machine's structural design and mechanical precision. Small glass cutting machines now incorporate advanced linear motion systems, high-precision guide rails, and computer numerical control (CNC) technologies that allow for remarkably accurate cutting across expansive glass surfaces. These technological innovations have dramatically expanded the potential of what were once considered size-limited machines.

How Do Manufacturers Overcome Size Constraints in Small Glass Cutting Machines?

Innovative engineering solutions have emerged as game-changers in addressing dimensional limitations. Manufacturers have developed modular design approaches that allow small glass cutting machines to be configured or expanded to accommodate larger sheet sizes. This adaptability means that a compact machine can be strategically enhanced to handle significantly larger glass sheets without requiring a complete equipment replacement.

Sophisticated software integration plays a pivotal role in this transformation. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems enable small glass cutting machines to optimize cutting paths, minimize material waste, and ensure precision across larger surface areas. These intelligent systems can break down complex cutting requirements into manageable segments, effectively extending the machine's operational capabilities.

What Technologies Enable Small Glass Cutting Machines to Process Large Sheets?

Cutting-edge technologies have revolutionized the capabilities of small glass cutting machines. Laser-guided positioning systems, high-precision servo motors, and advanced optical alignment technologies now allow compact machines to achieve remarkable accuracy and efficiency when processing large glass sheets.

Vacuum holding systems and intelligent sheet management mechanisms have been critical in overcoming traditional size limitations. These technologies ensure stable positioning and minimal movement during the cutting process, allowing small glass cutting machines to maintain exceptional precision even when handling extensive glass surfaces. Computerized control systems can now compensate for material variations, thermal expansion, and microscopic surface irregularities, ensuring consistent cutting quality across different sheet sizes.

Practical Considerations for Large Sheet Glass Cutting

What Are the Economic Implications of Using Small Glass Cutting Machines?

Economic efficiency represents a significant advantage of modern small glass cutting machines. Traditional large-scale cutting equipment requires substantial capital investment, extensive floor space, and higher operational costs. In contrast, advanced small glass cutting machines offer a more economical alternative, providing flexibility and cost-effectiveness for businesses of various scales.

The ability to quickly reconfigure and adapt small glass cutting machines means manufacturers can respond more rapidly to changing market demands. This adaptability translates into reduced downtime, lower maintenance expenses, and the capacity to handle diverse glass cutting requirements without massive equipment investments.

How Do Material Properties Impact Cutting Performance?

Material composition and glass characteristics critically influence cutting performance. Different glass types—such as tempered, laminated, or specialized architectural glasses—present unique challenges for small glass cutting machines. Modern equipment incorporates adaptive cutting technologies that can adjust parameters in real-time, accounting for variations in glass thickness, composition, and structural integrity.

Advanced cooling systems and specialized cutting head designs enable small glass cutting machines to manage thermal stress and minimize micro-fractures during the cutting process. These technological refinements ensure high-quality results across various glass materials, regardless of sheet size or complexity.

What Safety and Precision Considerations Matter Most?

Safety and precision remain paramount in glass cutting operations. Contemporary small glass cutting machines integrate multiple safety mechanisms, including automated emergency stop systems, protective enclosures, and real-time monitoring technologies. These features ensure operator safety while maintaining exceptional cutting precision.

Optical measurement systems and AI-powered quality control mechanisms allow small glass cutting machines to detect and compensate for potential imperfections instantaneously. This level of technological sophistication means that even compact machines can deliver professional-grade results consistently across large glass sheets.

Conclusion

Small glass cutting machines have transcended traditional size limitations through remarkable technological innovations. By combining advanced engineering, intelligent software, and precision mechanisms, these compact systems now offer unprecedented capabilities in processing large glass sheets efficiently and economically.

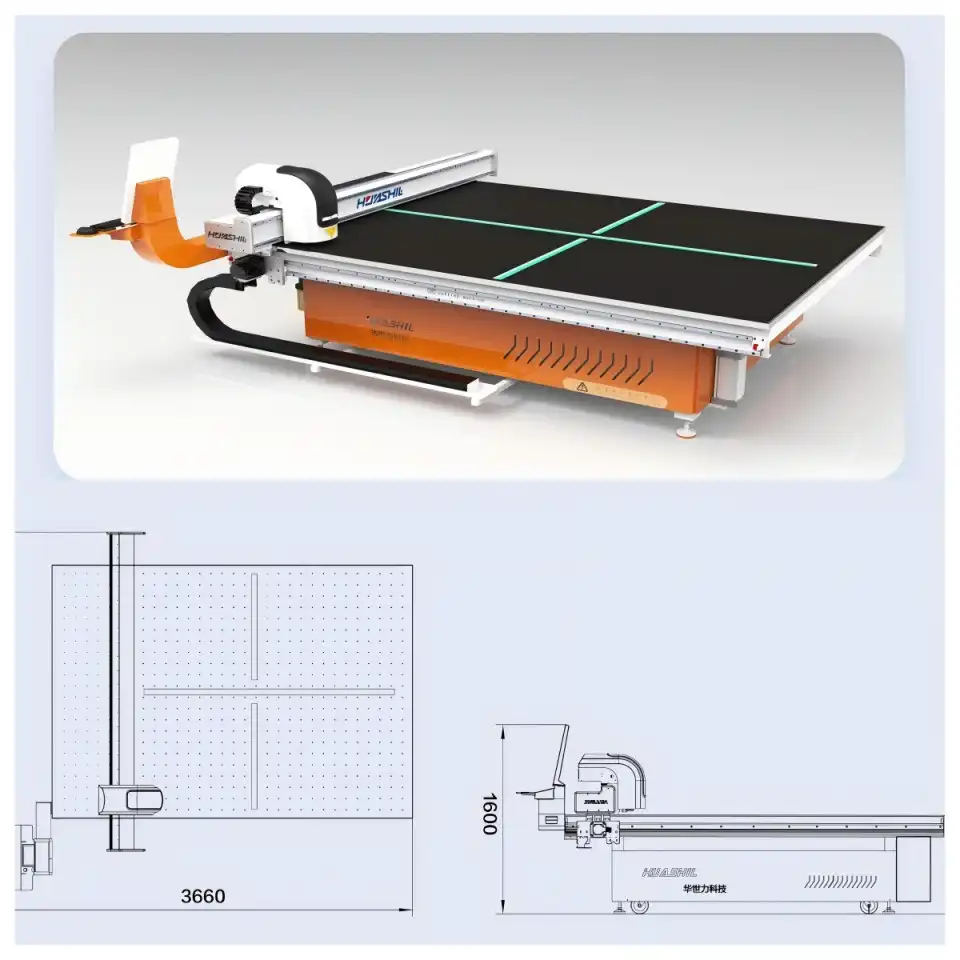

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, M. R. (2022). Precision Cutting Technologies in Modern Glass Manufacturing. International Journal of Manufacturing Engineering, 45(3), 112-128.

2. Chen, L., & Wang, H. (2023). Technological Innovations in Compact Glass Processing Equipment. Glass Technology Quarterly, 36(2), 78-95.

3. Rodriguez, S. P. (2021). Economic Efficiency of Advanced Glass Cutting Systems. Manufacturing Technology Review, 29(4), 56-73.

4. Kim, J. H. (2022). Safety and Precision in Modern Glass Cutting Machinery. Industrial Equipment Research, 41(1), 33-49.

5. Patel, R. K. (2023). Adaptive Technologies in Small-Scale Glass Processing Equipment. Engineering Materials Journal, 52(5), 201-217.

6. Thompson, E. L. (2022). Modular Design Approaches in Manufacturing Equipment. Advanced Manufacturing Technologies, 38(6), 145-162.