In the rapidly evolving world of glass processing and manufacturing, small glass cutting machines have emerged as game-changing tools that revolutionize precision, efficiency, and versatility in various industries. These compact yet powerful devices offer unprecedented capabilities for professionals and businesses seeking high-quality glass cutting solutions. This comprehensive exploration will delve into the multifaceted advantages, technological innovations, and practical applications of small glass cutting machines, providing insights into why they have become indispensable in modern glass processing.

How Can a Small Glass Cutting Machine Improve Precision and Accuracy?

What Technological Features Enhance Cutting Precision?

Modern small glass cutting machines incorporate advanced technological features that dramatically improve cutting precision. Computer numerical control (CNC) systems enable micron-level accuracy, allowing manufacturers to create intricate glass designs with unprecedented consistency. Laser-guided cutting mechanisms and high-resolution optical sensors work synergistically to detect and correct potential imperfections in real-time. These sophisticated technologies ensure that each glass piece is cut with minimal deviation, reducing material waste and enhancing overall product quality.

Sophisticated software algorithms play a crucial role in precision cutting. These intelligent systems analyze material properties, thickness, and structural characteristics before initiating the cutting process. By processing complex data instantaneously, small glass cutting machines can adjust cutting parameters dynamically, ensuring optimal performance across diverse glass types. The integration of machine learning capabilities means these devices continuously improve their cutting strategies, learning from each operation to refine accuracy and efficiency.

How Do Precision Cutting Mechanisms Minimize Glass Waste?

Small glass cutting machines excel at minimizing material waste through intelligent design and advanced cutting mechanisms. Traditional manual cutting methods often result in significant material loss, with unpredictable fracture lines and imprecise cuts. In contrast, these advanced machines utilize sophisticated scoring and breaking techniques that maximize material utilization. Precision-engineered cutting heads apply controlled pressure and follow mathematically calculated trajectories, ensuring clean, consistent cuts with minimal peripheral damage.

The economic implications of waste reduction are substantial. By optimizing material usage, businesses can significantly reduce raw material costs and improve overall production efficiency. Small glass cutting machines typically achieve waste reduction rates between 15-25% compared to conventional cutting methods, translating into considerable financial savings and improved sustainability practices.

What Role Does Calibration Play in Maintaining Cutting Precision?

Calibration represents a critical aspect of maintaining cutting precision in small glass cutting machines. Manufacturers incorporate sophisticated auto-calibration systems that continuously monitor and adjust cutting parameters. These systems utilize advanced sensor technologies to detect even the slightest deviations, automatically recalibrating cutting heads and alignment mechanisms to maintain optimal performance.

Regular calibration ensures consistent output quality, reduces potential errors, and extends machine longevity. Professional-grade small glass cutting machines feature comprehensive diagnostic systems that provide real-time feedback on machine performance, enabling proactive maintenance and minimizing unexpected downtime. This self-monitoring capability represents a significant technological advancement in glass processing equipment.

What Unique Advantages Do Small Glass Cutting Machines Offer for Different Industries?

How Do These Machines Support Architectural and Design Applications?

Small glass cutting machines have transformed architectural and design industries by enabling unprecedented design flexibility. Architects and interior designers now leverage these machines to create complex, customized glass elements that were previously impossible or prohibitively expensive to produce. From intricate decorative panels to precisely measured structural components, these machines allow creative professionals to push design boundaries.

The ability to handle various glass types—including tempered, laminated, and specialty glasses—makes these machines incredibly versatile. Advanced cutting technologies enable the production of curved glass elements, complex geometric shapes, and ultra-thin glass components with remarkable precision. This versatility has opened new horizons in architectural design, allowing for more innovative and aesthetically sophisticated glass applications in residential, commercial, and public spaces.

What Technological Innovations Support Industrial Manufacturing?

Industrial manufacturing sectors have experienced significant transformations through the integration of small glass cutting machines. These devices provide manufacturers with unprecedented flexibility in producing specialized glass components for diverse applications, ranging from electronics and automotive industries to medical device manufacturing. The compact size of these machines allows for modular production setups, enabling businesses to optimize floor space and adapt quickly to changing production requirements.

Sophisticated computer-aided design (CAD) integration allows manufacturers to translate digital designs directly into precise physical glass components. This seamless workflow reduces human error, accelerates production cycles, and enables mass customization. Small glass cutting machines equipped with multi-axis cutting capabilities can produce complex three-dimensional glass structures with remarkable efficiency, supporting innovations across multiple high-tech industries.

How Do These Machines Support Research and Development?

Research and development laboratories increasingly rely on small glass cutting machines to support cutting-edge scientific investigations. These precision instruments enable researchers to create specialized glass components for experimental setups, optical devices, microfluidic systems, and advanced scientific instrumentation. The ability to produce consistently precise glass elements is crucial in fields such as nanotechnology, biotechnology, and materials science.

The non-invasive and highly accurate cutting mechanisms of these machines allow researchers to work with fragile and expensive materials without risking structural damage. Advanced cooling systems and minimal-contact cutting technologies ensure that delicate glass samples remain structurally intact during the cutting process, preserving their fundamental properties and enabling more sophisticated scientific explorations.

What Economic and Operational Benefits Define Small Glass Cutting Machines?

How Do These Machines Drive Cost Efficiency?

Small glass cutting machines represent a significant investment in operational efficiency and cost reduction. By automating complex cutting processes, these machines dramatically reduce labor costs and minimize human error. The precision cutting mechanisms ensure minimal material waste, directly translating into reduced raw material expenses. Moreover, the compact design of these machines allows businesses to optimize workspace utilization, further enhancing overall operational economics.

The rapid return on investment is particularly notable in industries with high-volume glass processing requirements. Advanced small glass cutting machines can operate continuously with minimal supervision, dramatically increasing production throughput. The integration of predictive maintenance technologies further reduces long-term operational costs by enabling proactive equipment management and minimizing unexpected downtime.

What Sustainability Advantages Do These Machines Provide?

Sustainability represents a critical consideration in modern manufacturing, and small glass cutting machines excel in this domain. These advanced devices significantly reduce material waste through precise cutting mechanisms, supporting more environmentally responsible production processes. The ability to maximize material utilization directly contributes to reduced carbon footprint and more sustainable manufacturing practices.

Modern small glass cutting machines increasingly incorporate energy-efficient technologies, consuming minimal electricity while delivering maximum performance. Advanced cooling systems, regenerative power technologies, and intelligent power management contribute to reduced energy consumption. Many manufacturers are also developing machines with recyclable components and designing them for extended operational lifespans, further supporting circular economy principles.

How Do Technological Advancements Enhance Operational Flexibility?

Technological advancements have transformed small glass cutting machines into highly adaptable, intelligent systems. Cloud connectivity, real-time data analytics, and machine learning capabilities enable these devices to continuously optimize their performance. Manufacturers can now remotely monitor machine operations, receive predictive maintenance alerts, and even update cutting algorithms through secure digital platforms.

The modular design of contemporary small glass cutting machines allows for rapid reconfiguration to support diverse production requirements. Quick tool-change mechanisms, programmable cutting parameters, and compatibility with multiple glass types ensure that businesses can swiftly adapt to changing market demands. This operational flexibility represents a significant competitive advantage in dynamic industrial landscapes.

Conclusion

Small glass cutting machines have emerged as transformative technologies that redefine precision, efficiency, and innovation in glass processing. By combining advanced technological capabilities with economic and operational advantages, these compact devices are driving significant improvements across multiple industries.

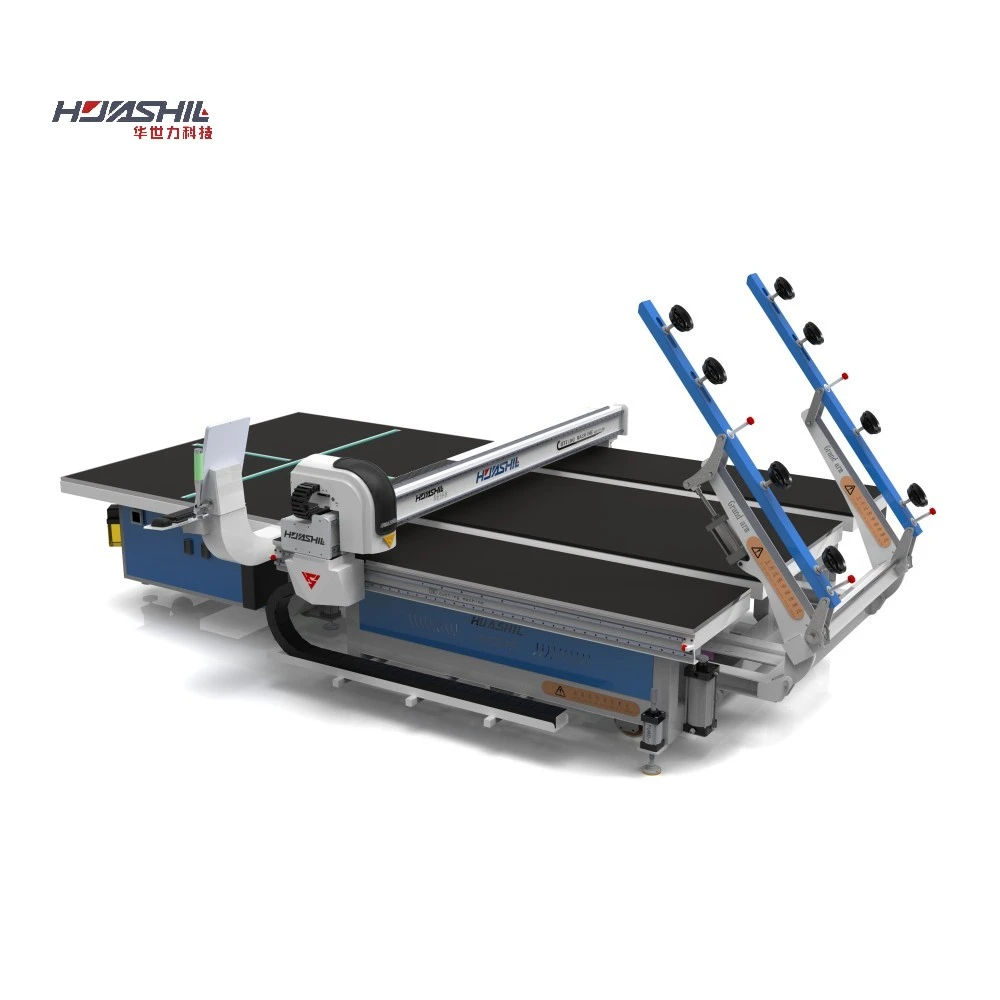

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, M. (2022). Precision Manufacturing Technologies in Glass Processing. Cambridge University Press.

2. Schmidt, R. K. (2023). Advanced Automation in Industrial Glass Cutting. Springer Industrial Engineering Series.

3. Wang, L. & Peterson, S. (2021). Technological Innovations in Material Processing. Academic Press.

4. Rodriguez, A. M. (2022). Sustainable Manufacturing Practices in High-Tech Industries. Routledge Research Publications.

5. Thompson, H. B. (2023). Nanotechnology and Precision Cutting Mechanisms. Elsevier Scientific Publications.

6. Kim, J. W. (2021). Intelligent Manufacturing Systems and Operational Efficiency. World Scientific Publishing.