In today's competitive glass industry, manufacturers constantly seek ways to optimize production processes and meet market demands. Equipment customization is crucial for enhancing efficiency, quality, and profitability. This article explores how glass manufacturing equipment can be tailored to specific production requirements, the benefits of customization, and key considerations for manufacturers investing in customized solutions.

What factors determine the customization options for glass manufacturing equipment?

Production Scale and Capacity Requirements

Production scale significantly influences glass manufacturing equipment customization decisions. Large-scale manufacturers require robust equipment designed for continuous operation with minimal downtime, including larger furnaces, extended annealing lehrs, and sophisticated automated handling systems. Customization may involve integrating multiple production lines and implementing redundant systems to prevent costly shutdowns.

Smaller manufacturers benefit from more flexible equipment that can be quickly reconfigured for different products in smaller batches. These customizations might include modular furnace designs, interchangeable molds, and versatile cutting systems. Medium-sized operations typically focus on balancing throughput with flexibility. Equipment suppliers increasingly offer scalable solutions where additional capacity modules can be integrated as manufacturers grow, providing a customized growth path aligned with business development.

Glass Type and Composition Specifications

Different glass compositions require specialized manufacturing equipment due to their unique properties. Float glass production equipment must be customized for specific soda-lime-silica compositions, including precise temperature controls in the tin bath. Borosilicate glass manufacturing requires equipment that withstands higher melting temperatures and manages increased thermal shock resistance.

Specialty glass production demands even more significant customization. Pharmaceutical glass requires exceptional chemical durability and precision forming capabilities, while optical glass manufacturing must ensure homogeneity and freedom from defects. Equipment for colored glass needs additional systems for consistent colorant mixing, and lead glass manufacturing demands specialized environmental controls and safety measures. These customizations extend beyond melting and forming equipment to include specialized annealing processes, quality control systems, and handling mechanisms designed for specific glass compositions.

Production Process Integration Requirements

Seamless integration of new glass manufacturing equipment into existing production workflows is critical for operational efficiency. Modern facilities often combine legacy systems with newer technologies, creating integration challenges that equipment manufacturers must address. Customized interface solutions ensure new equipment communicates effectively with existing plant control systems, preventing data silos and enabling comprehensive production monitoring.

Spatial constraints frequently necessitate dimensional customization of equipment. Suppliers must engineer solutions that fit available spaces while maintaining performance. This might involve reconfiguring standard layouts, developing vertical arrangements, or creating modular systems. Energy integration represents another crucial consideration, with equipment designed to recover waste heat from furnaces to support other processes. Material handling systems must align with existing factory logistics, ensuring smooth transitions between processing stages without bottlenecks.

How does customized glass manufacturing equipment impact production efficiency and quality?

Automation and Precision Control Enhancements

Modern glass manufacturing equipment incorporates sophisticated automation systems and precision controls tailored to specific production requirements. Advanced PLC systems can be programmed with product-specific parameters, allowing rapid changeovers between different glass specifications without extensive manual adjustments. In float glass production, customized control systems automatically adjust furnace temperatures, tin bath conditions, and annealing parameters based on specific quality requirements.

Machine vision systems can be tailored to detect specific defects relevant to particular glass products. By integrating customized sensors throughout the production line, manufacturers collect real-time data on multiple quality parameters simultaneously. This information feeds into statistical process control systems that identify trends before quality deviations occur. Companies investing in these customized automation solutions report significant improvements in consistency, with some achieving up to 30% reductions in quality-related rejections and substantial decreases in operator intervention requirements.

Energy Efficiency and Sustainability Improvements

Customizing glass manufacturing equipment for enhanced energy efficiency delivers significant value. Customized recuperative and regenerative systems can be designed based on a manufacturer's specific production profile, capturing waste heat and redirecting it to preheat materials or combustion air. These systems can be precisely configured based on production volume, glass type, and facility layout. A float glass manufacturer might implement a customized regenerative furnace design that reduces energy consumption by up to 25% compared to standard configurations.

Advanced combustion control systems can be tailored to specific fuel types and quality requirements. Oxygen-fuel firing systems can reduce energy consumption by 20-45% compared to conventional systems while reducing emissions. Customized electric boosting configurations provide supplementary heat precisely where needed, optimizing energy distribution. Variable speed drives on motors can be programmed according to actual production requirements rather than running at constant speeds. These customizations reduce operating costs and enhance sustainability credentials.

Product Versatility and Changeover Efficiency

The ability to manufacture diverse glass products on the same production line is increasingly important as market demands evolve. Customized equipment enhances versatility through features engineered for quick changeovers and multi-product capability. Forming equipment can be designed with rapid-change mold systems that allow switching between different product dimensions in minutes rather than hours, using standardized connection points and automated adjustment mechanisms.

Digital infrastructure controlling glass manufacturing equipment can store hundreds of product-specific parameter sets, allowing operators to recall precise settings with minimal input. This digitalization reduces potential for human error while accelerating transitions between products. For specialty or architectural glass, customized cutting and processing equipment can be designed with modular tooling stations that accommodate various finishing requirements without complete line reconfiguration. Advanced equipment may feature self-adjusting capability, where integrated measurement systems automatically detect product changes and adjust downstream parameters accordingly.

What are the key considerations when investing in customized glass manufacturing equipment?

Return on Investment Analysis and Cost Considerations

When evaluating investments in customized glass manufacturing equipment, manufacturers must conduct comprehensive ROI analyses. The initial capital outlay typically exceeds standard alternatives by 15-30%, necessitating careful financial justification. The analysis should quantify expected productivity improvements, including increased throughput, reduced downtime during changeovers, and decreased reject rates. Operational cost reductions represent another critical factor, with energy efficiency improvements potentially saving hundreds of thousands of dollars annually.

Manufacturers must consider the equipment's adaptability to future production requirements. Glass manufacturing equipment typically remains in service for 10-20 years, making flexibility valuable. Customizations allowing future upgrades might carry higher initial costs but provide superior long-term value. Maintenance considerations also impact long-term costs, with some customizations designed to simplify maintenance procedures or extend service intervals. Smart equipment with customized predictive maintenance capabilities may reduce unexpected downtime costs, which can exceed $10,000 per hour in large operations.

Supplier Expertise and Collaborative Design Process

The success of customized glass manufacturing equipment implementations depends significantly on selecting suppliers with demonstrated expertise and willingness to engage in collaborative design processes. Experienced suppliers bring industry knowledge that can prevent costly design errors and identify optimization opportunities. Manufacturers should investigate the supplier's track record with similar projects and ensure their engineering team understands glass chemistry, thermodynamics, and quality requirements.

The collaborative design process requires structured methodology and clear communication channels. Leading suppliers typically employ dedicated application engineers who spend time on-site understanding workflows and objectives before proposing solutions. Effective collaboration tools such as 3D modeling and simulation software enable manufacturers to visualize proposed customizations before fabrication begins. The supplier should incorporate modifications based on operator input, recognizing that shop floor personnel possess valuable insights regarding implementation challenges.

Future Scalability and Technology Adaptation Capacity

Forward-thinking manufacturers must consider how equipment investments will accommodate future requirements and technological advancements. Valuable customized equipment incorporates design principles facilitating expansion and upgrades without complete system replacement. Modular architecture represents a key approach to ensuring scalability, with equipment designed as interconnected but somewhat independent subsystems that can be upgraded individually as needs evolve.

Digital infrastructure represents another critical dimension of adaptability. Customized control systems should feature open architecture designs that can incorporate future sensing technologies and data analytics capabilities. Equipment suppliers increasingly offer "digital twin" technologies as customization options, creating virtual replicas of physical systems that facilitate offline testing of process modifications. From a hardware perspective, customized designs should include accommodation for future technology integration, such as reserved space for additional sensors and accessible mounting points for supplementary components.

Conclusion

The customization of glass manufacturing equipment represents a strategic advantage for manufacturers seeking to optimize production processes for specific needs. Factors such as production scale, glass composition, and integration requirements significantly influence customization options. These tailored solutions deliver tangible benefits in efficiency, quality, and versatility while presenting important considerations around investment returns, supplier selection, and future adaptability. By carefully approaching equipment customization, glass manufacturers can position themselves for long-term success in an increasingly competitive marketplace.

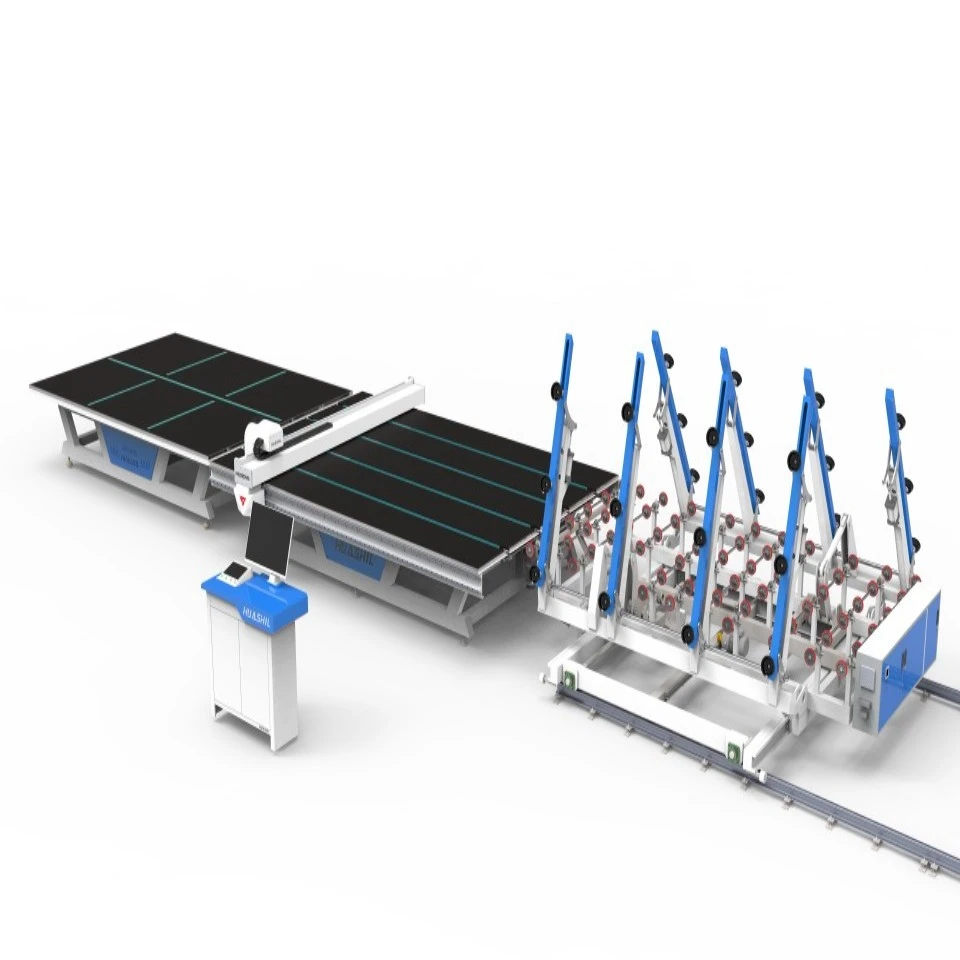

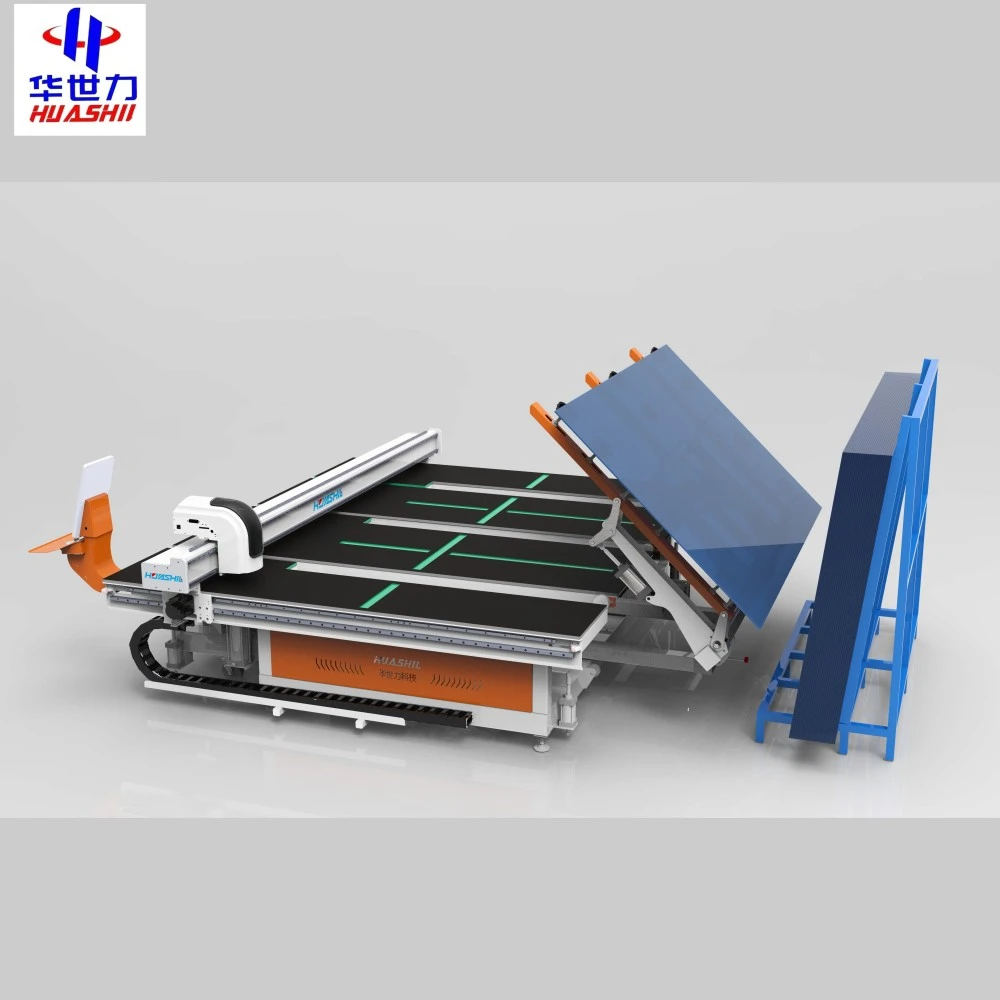

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include Mirror Cutting Machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Zhang, L., & Thompson, R. (2023). "Advances in Customized Glass Manufacturing Equipment: A Comprehensive Review." Journal of Glass Technology, 45(3), 278-295.

2. Henderson, M., Phillips, J., & Wang, Y. (2022). "Energy Efficiency Optimization in Modern Glass Production Equipment." International Journal of Industrial Engineering, 19(2), 142-159.

3. Patel, S., & Nakamura, H. (2023). "Integration Challenges and Solutions for Next-Generation Glass Processing Equipment." Glass Manufacturing Quarterly, 37(1), 56-73.

4. Müller, K., & Chen, L. (2024). "Economic Analysis of Customized vs. Standard Equipment in Float Glass Production." Journal of Manufacturing Economics, 28(4), 412-429.

5. Rodriguez, A., & Smith, B. (2023). "Automation Trends in Contemporary Glass Manufacturing: Industry 4.0 Applications." Industrial Automation Review, 15(2), 189-205.

6. Wilson, E., Takahashi, M., & Adebayo, F. (2024). "Sustainability Metrics for Modern Glass Processing Equipment: A Life Cycle Assessment." Journal of Sustainable Manufacturing, 12(3), 267-284.