Selecting the appropriate glass processing equipment is a critical decision that can significantly impact your business's productivity, product quality, and bottom line. Whether you're establishing a new glass fabrication facility or upgrading existing machinery, understanding the various factors that influence equipment selection is essential for making informed decisions. This guide explores the key considerations for choosing glass processing equipment that aligns with your business needs, budget constraints, and production goals.

What factors should I consider when purchasing glass processing equipment?

Production Volume and Capacity Requirements

When evaluating glass processing equipment, production volume should be your primary consideration. The equipment must align with both current production needs and anticipate future growth. High-volume operations require robust glass processing equipment designed for continuous operation with minimal downtime. Smaller operations might benefit from more compact, versatile equipment that offers flexibility without unnecessary capacity. Analyze your production data and forecast future demand to determine appropriate requirements. Manufacturers typically recommend selecting equipment with 20-30% additional capacity beyond current needs to accommodate growth. Inadequate capacity leads to production bottlenecks, while excess capacity represents inefficient capital allocation—both scenarios impact your business profitability.

Space Constraints and Facility Layout

Your facility's physical dimensions and layout play a crucial role in equipment selection. Modern glass processing equipment varies dramatically in size and configuration. Before purchasing, create a detailed floor plan that accounts for the equipment footprint, operational space, material storage, workflow paths, and safety clearances. Consider ceiling height restrictions and evaluate your facility's infrastructure capacity—adequate electrical supply, compressed air systems, water connections, and ventilation requirements. Some advanced glass processing equipment may require reinforced flooring due to weight considerations. Consulting with equipment suppliers early allows them to recommend configurations that optimize your available space while maintaining efficient workflow patterns.

Technical Specifications and Processing Requirements

The specific glass processing capabilities required depend entirely on your product offerings and quality standards. Determine which operations are essential: cutting, grinding, drilling, polishing, tempering, laminating, or specialized treatments. Modern glass processing equipment often combines multiple functions, enhancing efficiency but potentially increasing initial investment costs. Evaluate specifications including precision tolerances, maximum material dimensions, thickness capacities, cycle times, and automation levels. Processing speed must balance with quality outcomes. Consider the types of glass you'll be processing, as some equipment is optimized for specific varieties. Special considerations may include edge quality requirements, surface treatments, complex shape capabilities, or specialty glass compatibility.

How do I evaluate the cost-effectiveness of glass processing equipment?

Initial Investment vs. Long-term Value

The purchase price represents only part of the total ownership cost equation. High-quality glass processing equipment may command premium prices but often delivers superior durability, reliability, and performance that translates to lower lifetime costs. Analyze the expected service life, typically ranging from 10-20 years for quality machinery. Factor in depreciation schedules and potential resale value when calculating true ownership costs. While budget constraints are real considerations, purchasing underpowered equipment to save upfront costs frequently proves counterproductive, resulting in production limitations and premature replacement needs. Some manufacturers offer modular systems that allow for phased investment—starting with core capabilities and adding specialized glass processing equipment components as your business grows.

Operational Costs and Efficiency Metrics

Energy consumption represents a significant ongoing expense for glass processing equipment. Modern machines often incorporate energy-efficient technologies that reduce operational costs substantially compared to older models. Calculate potential energy savings over the equipment's lifespan as part of your return-on-investment analysis. Evaluate consumables requirements including cutting tools, grinding materials, lubricants, and replacement parts. Maintenance frequency and complexity also impact overall operational costs. Production efficiency directly affects profitability, so assess metrics like processing speed, changeover time between different product runs, scrap rates, and labor requirements. Advanced glass processing equipment with automated features typically reduces labor costs but may require higher-skilled operators. Request detailed operational cost data from manufacturers and, when possible, speak with current users about their real-world experiences.

Return on Investment Timeline

Calculating the ROI for glass processing equipment requires analyzing how the technology will impact your business operations and profitability. Quantify productivity improvements—faster processing times, reduced labor requirements, decreased material waste, and enhanced quality consistency all contribute to financial returns. Many businesses find that advanced glass processing equipment allows them to accept more complex, higher-margin projects. Estimate how equipment capabilities might expand your market reach or enable product diversification. Quality improvements can significantly impact ROI through reduced rework and fewer customer rejections. Most modern glass fabrication equipment should demonstrate payback periods between 2-5 years, depending on utilization rates and specific business circumstances. When evaluating competing options, assign appropriate value to intangible benefits like improved employee satisfaction and enhanced workplace safety that modern glass processing equipment often provides.

What should I know about manufacturer support and equipment reliability?

Warranty Coverage and Service Agreements

Comprehensive warranty coverage represents a manufacturer's confidence in their glass processing equipment and provides crucial financial protection for your business investment. Standard warranties typically cover parts and labor for 12-24 months, with premium equipment often offering extended options. Review warranty terms carefully, noting exclusions, claim procedures, and response time commitments. Beyond the initial warranty, service agreements offer ongoing protection and predictable maintenance costs. The most effective service agreements for glass processing equipment include regular inspections that identify potential issues before they cause failures. Consider geographic proximity to service technicians, as remote locations may experience longer response times. Many suppliers now offer remote diagnostics capabilities that allow technicians to troubleshoot issues quickly, often resolving problems without an on-site visit.

Technical Support and Training Resources

Even the most advanced glass processing equipment requires competent operators to deliver optimal results. Evaluate the manufacturer's training program thoroughness, format options, and ongoing availability. Initial training should cover operation, troubleshooting procedures, maintenance protocols, and optimization techniques. Beyond initial training, ongoing technical support accessibility can significantly impact your operational continuity. Assess the manufacturer's support structure: Do they offer 24/7 helpline access? What is their typical response time? Many providers now deliver support through multiple channels including phone, email, video calls, and online knowledge bases. Additionally, inquire about the availability of application specialists who can help optimize your specific production processes and develop solutions for unique glass fabrication challenges.

Reputation and Industry Track Record

A manufacturer's reputation within the glass processing industry provides valuable insights into equipment reliability and company stability. Research prospective suppliers thoroughly through industry publications, trade associations, customer testimonials, and independent review platforms. Equipment with proven reliability typically commands higher resale value and delivers better long-term value. Evaluate the manufacturer's business longevity and financial stability. Speak directly with current users of the glass processing equipment you're considering, requesting candid feedback about reliability, performance, and manufacturer responsiveness to issues. Many equipment suppliers will facilitate site visits to operational installations so you can observe machines in production environments similar to your own. The most respected glass processing equipment manufacturers continuously invest in research and development to incorporate new technologies and enhance performance.

Conclusion

Selecting the right glass processing equipment requires careful evaluation of your production needs, facility constraints, budget considerations, and long-term business goals. By thoroughly assessing factors like equipment capacity, technical specifications, cost-effectiveness, and manufacturer support, you can make a decision that optimizes your operations and positions your business for success. Remember that the ideal equipment choice balances initial investment with operational efficiency and long-term value, ultimately enhancing your competitive position in the glass fabrication market.

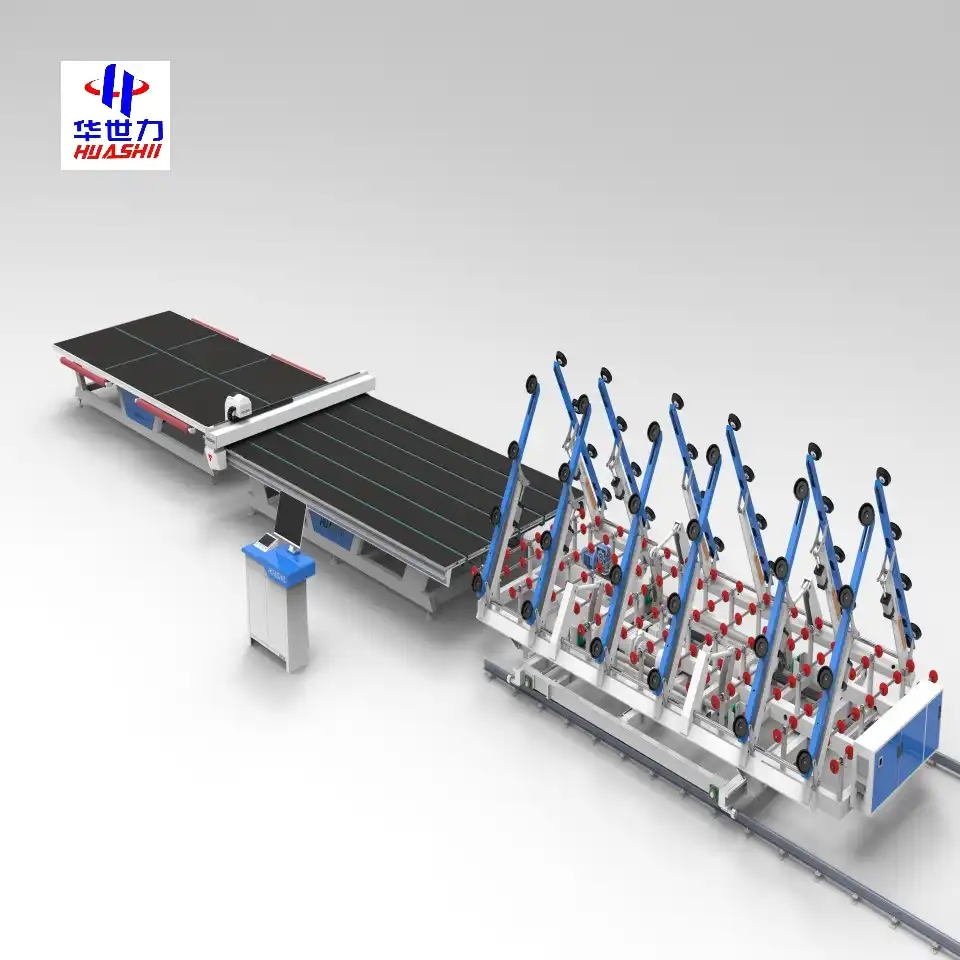

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include Mirror Cutting Machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, M. R., & Thompson, S. K. (2023). Advanced Manufacturing Technologies in Glass Processing: Equipment Selection Guidelines for Modern Fabricators. Journal of Glass Technology, 47(3), 215-229.

2. Chen, L., & Williams, P. (2022). Cost-Benefit Analysis of Automated Glass Processing Equipment for Small and Medium Enterprises. International Journal of Industrial Engineering, 18(2), 142-158.

3. Patel, A., & Rodriguez, C. (2023). Energy Efficiency in Glass Fabrication: Comparative Analysis of Contemporary Processing Equipment. Sustainable Manufacturing Review, 12(4), 375-391.

4. Glass Processing Association. (2024). Industry Benchmarking Report: Equipment Performance Metrics and Selection Criteria. GPA Publications, 9th Edition.

5. Schmidt, H., & Davis, R. (2023). Quality Assurance in Architectural Glass: The Role of Precision Equipment in Meeting Modern Standards. Building Materials Journal, 29(1), 82-97.

6. Kumar, V., Zhang, Y., & Fernandez, E. (2024). ROI Analysis Framework for Capital Investment in Glass Processing Technologies. Manufacturing Economics Quarterly, 31(2), 203-217.