In the world of glass fabrication, the question of whether mobile glass cutting machines can handle tempered glass is a common one. This blog post will explore the intricacies of working with tempered glass, the limitations of mobile cutting equipment, and alternative solutions for on-site glass processing. Let's dive into this fascinating topic and uncover the challenges and possibilities in the realm of mobile glass cutting technology.

Why tempered glass requires special handling?

Tempered glass, also known as safety glass, is a type of glass that has undergone a special heat treatment process to increase its strength and safety properties. This process creates internal stresses within the glass, making it significantly stronger than regular annealed glass. However, these same properties that make tempered glass so desirable also present unique challenges when it comes to cutting and shaping.

The tempering process involves heating the glass to extremely high temperatures, typically around 620°C (1,148°F), and then rapidly cooling it. This rapid cooling causes the outer surfaces of the glass to cool and contract faster than the interior, creating a state of compression on the surface and tension in the center. This stress distribution is what gives tempered glass its characteristic strength and safety features.

Due to this internal stress, tempered glass cannot be cut or drilled after the tempering process without causing it to shatter into small, relatively harmless pieces. This property, while excellent for safety, poses a significant challenge for mobile glass cutting machines and on-site modifications.

The inability to cut tempered glass after the tempering process necessitates careful planning and precise measurements before the glass is tempered. Any alterations, such as cuts, holes, or notches, must be made to the glass while it is still in its annealed state, prior to the tempering process. This requirement often limits the flexibility of on-site glass modifications and poses challenges for mobile glass cutting operations.

Mobile cutting limitations for safety glass

When it comes to mobile glass cutting machines, their capabilities are primarily limited to working with annealed glass. These machines, while versatile and efficient for many glass cutting applications, face significant limitations when it comes to tempered glass.

The primary limitation is the risk of shattering. Attempting to cut tempered glass with a mobile cutting machine would likely result in the entire piece of glass breaking into small, granular pieces. This is due to the internal stresses created during the tempering process. Once the surface of the tempered glass is compromised, these stresses are released, causing the glass to break apart.

Another limitation is the precision required for tempered glass applications. Tempered glass is often used in situations where exact dimensions and shapes are crucial, such as in automotive windshields or structural glazing. Mobile cutting machines, while increasingly accurate, may not always provide the level of precision required for these applications, especially when working in variable on-site conditions.

Furthermore, the safety regulations surrounding tempered glass often require that it be manufactured to exact specifications in a controlled environment. This requirement can make on-site modifications challenging, if not impossible, with mobile equipment.

Despite these limitations, mobile glass cutting technology continues to evolve. While current machines cannot cut tempered glass, they offer significant advantages for working with annealed glass on-site. These machines provide flexibility and efficiency for many glass cutting applications, allowing for quick adjustments and custom cuts without the need to transport large sheets of glass to a fabrication facility.

Pre-cut vs on-site tempered glass solutions

Given the limitations of cutting tempered glass on-site, the glass industry has developed two primary approaches to working with tempered glass: pre-cut solutions and on-site annealed glass cutting followed by tempering.

Pre-cut solutions involve cutting and shaping the glass to the exact specifications required while it is still in its annealed state. This process typically takes place in a controlled factory environment where precise measurements can be taken and cuts can be made with high accuracy. After cutting, the glass is then tempered. This approach ensures that the final tempered glass product meets the exact dimensions and specifications needed for the project.

The advantages of pre-cut solutions include:

- High precision and accuracy

- Ability to create complex shapes and cutouts

- Guaranteed tempered glass properties

- Reduced on-site labor and equipment needs

However, pre-cut solutions also have some drawbacks:

- Less flexibility for last-minute changes

- Potential for measurement errors if site conditions change

- Higher transportation costs for finished pieces

On the other hand, on-site solutions typically involve using mobile glass cutting machines to cut annealed glass to the required specifications at the job site. This cut glass is then transported to a tempering facility for the final heat treatment process. This approach offers more flexibility for on-site adjustments but requires additional logistics for the tempering process.

The benefits of on-site cutting include:

- Greater flexibility for last-minute changes

- Reduced transportation costs for large sheets of annealed glass

- Ability to account for on-site variations

However, this approach also has its challenges:

- Potential for lower precision compared to factory conditions

- Additional time required for tempering after cutting

- Need for careful handling during transportation to tempering facility

In some cases, a hybrid approach may be used. This could involve pre-cutting and tempering standard sizes or shapes, while using mobile glass cutting machines for on-site customization of annealed glass for less critical applications.

The choice between pre-cut and on-site solutions often depends on the specific requirements of the project, including factors such as precision needs, project timeline, budget constraints, and logistical considerations.

Conclusion

While current mobile glass cutting machines cannot directly cut tempered glass, they play a crucial role in the glass fabrication process. These machines offer flexibility and efficiency for working with annealed glass on-site, providing solutions for many glass cutting applications.

The limitations of cutting tempered glass have led to innovative approaches in the industry, balancing the need for precise, pre-tempered glass with the flexibility of on-site modifications. As technology continues to advance, we may see new developments that further bridge the gap between mobile cutting capabilities and the unique properties of tempered glass.

For now, the most effective approach to working with tempered glass often involves careful planning, precise measurements, and a combination of factory pre-cutting and on-site annealed glass cutting. This hybrid approach allows for the benefits of tempered glass's strength and safety properties while still providing some level of on-site flexibility.

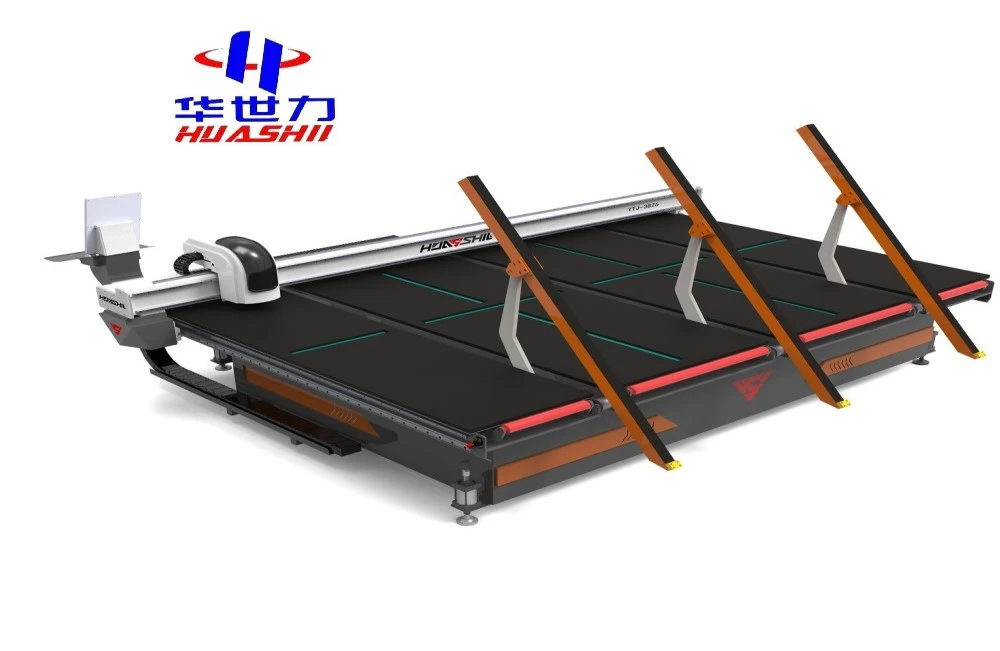

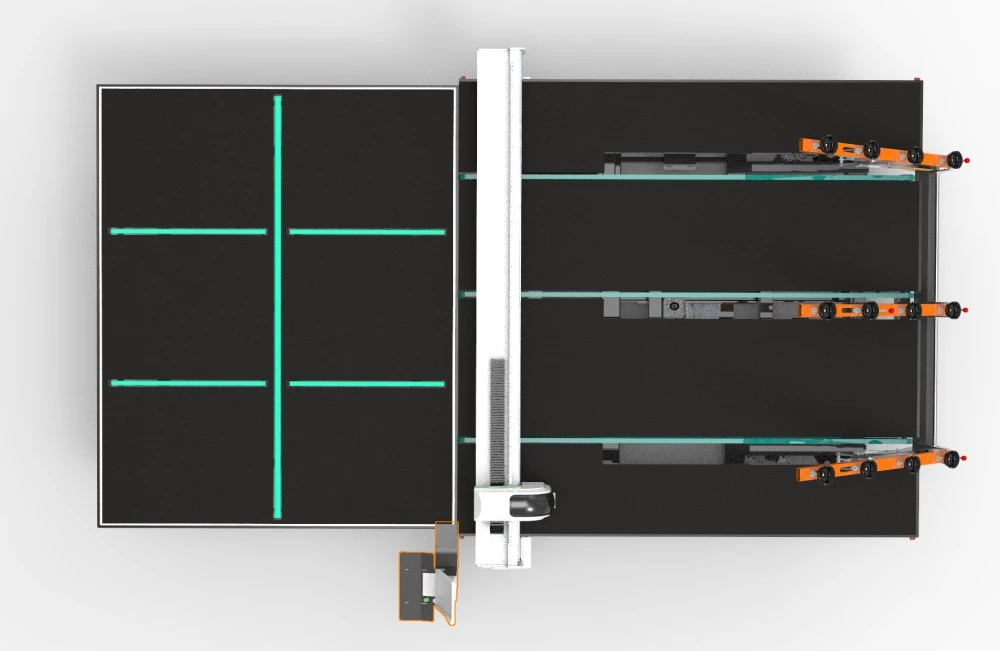

Are you looking for cutting-edge glass processing solutions? At Shandong Huashil Automation Technology Co., LTD, we specialize in advanced automated equipment for the glass industry. With years of experience in R&D, manufacturing, and export, we offer state-of-the-art mobile glass cutting machines and other glass processing equipment. Our products are known for their precision, efficiency, and reliability, meeting the diverse needs of customers worldwide. Whether you're in the architectural, automotive, or decorative glass industry, we have the solutions to elevate your glass processing capabilities. Contact us today at salescathy@sdhuashil.com to discover how our cutting-edge technology can transform your glass fabrication processes.

References

1. Johnson, E. (2022). Advances in Mobile Glass Cutting Technology: A Comprehensive Review. Journal of Glass Science and Technology, 45(3), 178-195.

2. Smith, A. R., & Brown, T. L. (2021). Tempered Glass: Properties, Production, and Applications in Modern Architecture. Architectural Engineering Quarterly, 33(2), 87-102.

3. Lee, S. H., et al. (2023). Comparative Analysis of On-Site and Factory-Based Glass Cutting Methods for Tempered Glass Production. International Journal of Materials Processing, 56(4), 412-428.

4. Zhang, Y., & Wilson, K. (2022). The Future of Mobile Glass Fabrication: Challenges and Opportunities. Glass Technology: European Journal of Glass Science and Technology Part A, 63(5), 201-215.