Curtain Wall Installation Uses

Curtain walls are a hallmark of modern architecture, providing sleek, transparent facades for commercial and residential buildings alike. The integration of mobile glass cutting machines into curtain wall installation has transformed this process, making it more efficient and precise than ever before.

One of the primary advantages of using these machines for curtain wall installations is the ability to make real-time adjustments. Construction sites are dynamic environments, and measurements can sometimes shift during the building process. With a mobile cutting machine on-site, glaziers can quickly adapt to these changes, cutting glass panels to the exact specifications required, even if they differ from the original plans.

The precision offered by these machines is unparalleled. They can achieve cuts with tolerances as tight as ±0.1mm, ensuring a perfect fit for each panel. This level of accuracy is crucial for curtain walls, where even minor discrepancies can lead to issues with weatherproofing or aesthetic imperfections.

Moreover, these machines can handle a variety of glass types and thicknesses commonly used in curtain wall systems. From tempered glass to laminated safety glass, the versatility of mobile cutting machines allows for seamless integration of different glass types within the same curtain wall structure.

The time-saving aspect of on-site cutting cannot be overstated. Traditional methods often involved measuring on-site, then sending specifications back to a factory for cutting. This process was not only time-consuming but also left room for errors in communication or measurement. With mobile cutting machines, the entire process happens on-site, dramatically reducing installation time and minimizing the potential for costly mistakes.

Additionally, these machines often come equipped with software that can interface with building information modeling (BIM) systems. This integration allows for a more streamlined workflow, where digital designs can be directly translated into cutting instructions, further enhancing accuracy and efficiency.

On-Site Mirror Cutting for Interiors

The application of mobile glass cutting machines extends beyond exterior work, proving invaluable for interior design and finishing. On-site mirror cutting has become a game-changer for contractors working on hotels, residential developments, and commercial spaces where custom mirrors are a key design element.

One of the most significant advantages of on-site mirror cutting is the ability to create bespoke designs that perfectly fit the space. Interior designers often envision unique mirror shapes and sizes that complement the overall aesthetic of a room. With a mobile cutting machine, these visions can be realized with precision, without the need for pre-ordering or estimating sizes.

The flexibility offered by these machines is particularly beneficial when dealing with irregularities in wall surfaces or custom-built furniture. For instance, in renovations of older buildings where walls may not be perfectly straight, on-site cutting allows for real-time adjustments to ensure a flawless fit. This level of customization was previously difficult and expensive to achieve.

Another crucial aspect is the reduction in material waste. By cutting mirrors on-site, contractors can optimize the use of larger mirror sheets, minimizing offcuts and reducing overall material costs. This not only makes the process more cost-effective but also aligns with sustainable construction practices by reducing waste.

The precision of these machines also plays a vital role in creating complex mirror installations. Intricate designs involving multiple mirror pieces, such as mosaic-style walls or geometric patterns, can be executed with incredible accuracy. This precision ensures that each piece fits perfectly with its neighbors, creating seamless and stunning visual effects.

Safety is another key consideration when working with mirrors, especially in construction environments. Mobile cutting machines often come equipped with safety features that minimize the risk of injury during the cutting process. Additionally, by reducing the need to transport pre-cut mirrors to the site, there's a decreased risk of breakage and associated injuries.

The efficiency gained from on-site cutting significantly impacts project timelines. Interior finishing is often on the critical path of construction schedules, and delays can have cascading effects on project completion. By eliminating the back-and-forth between site measurements and off-site cutting, projects can progress more smoothly and rapidly.

Custom Balcony Railing Fabrication

The integration of mobile glass cutting machines in custom balcony railing fabrication has opened up new possibilities in architectural design and safety. Glass balustrades have become increasingly popular in both residential and commercial construction, offering unobstructed views while providing essential safety features.

One of the primary advantages of using mobile cutting machines for balcony railings is the ability to create custom shapes and sizes on-site. This is particularly valuable when dealing with curved or irregularly shaped balconies. The precision cutting capabilities of these machines allow for the creation of glass panels that follow the exact contours of the balcony edge, resulting in a sleek, seamless appearance.

The on-site nature of these machines also allows for immediate problem-solving. In construction, it's not uncommon to encounter unexpected issues or last-minute design changes. With a mobile cutting machine, adjustments can be made in real-time, avoiding costly delays that would otherwise occur if panels needed to be reordered or re-fabricated off-site.

Safety is paramount in balcony railing design, and these machines contribute significantly to ensuring compliance with building codes and safety standards. They can precisely cut holes for fixings and create perfectly smooth edges, which are crucial for the structural integrity and safety of glass balustrades. The ability to make these precise cuts on-site ensures that each panel fits perfectly within the railing system, eliminating gaps or weak points.

The versatility of mobile cutting machines extends to the types of glass that can be used for balcony railings. From toughened safety glass to laminated options, these machines can handle a variety of materials, allowing designers to choose the most appropriate glass type for each project's specific requirements and aesthetic goals.

Another significant advantage is the reduction in transportation costs and risks. Transporting large, pre-cut glass panels to a construction site can be expensive and risky, with the potential for damage during transit. By cutting the glass on-site, these risks are minimized, and the overall cost of the project can be reduced.

The precision of these machines also allows for the incorporation of complex design elements in balcony railings. Frosted patterns, company logos, or decorative etching can be accurately replicated across multiple panels, ensuring consistency in design throughout large-scale projects.

Furthermore, the efficiency of on-site cutting significantly reduces installation time. This is particularly beneficial in high-rise construction, where balcony installation is often on the critical path of the project timeline. Faster installation means quicker project completion and potentially earlier occupancy, which can have significant financial implications for developers.

The use of mobile glass cutting machines in balcony railing fabrication also contributes to sustainability efforts in construction. By enabling precise cuts and reducing waste, these machines help in optimizing material usage. This not only reduces costs but also aligns with green building practices, which are increasingly important in modern construction projects.

Conclusion

The applications of mobile glass cutting machines in construction are vast and continually expanding. From curtain wall installations to custom mirror cutting and balcony railing fabrication, these versatile tools are revolutionizing the way we approach glass work in construction. They offer unparalleled precision, efficiency, and flexibility, enabling contractors to meet the increasingly complex demands of modern architectural design.

As we look to the future, it's clear that mobile glass cutting machines will play an even more significant role in construction. Their ability to integrate with digital design tools, contribute to sustainable practices, and enhance on-site efficiency makes them an invaluable asset in the industry.

For construction professionals looking to stay ahead of the curve and deliver exceptional results, investing in mobile glass cutting technology is not just an option – it's a necessity. By embracing these innovative tools, contractors can enhance their capabilities, improve project outcomes, and ultimately, transform the way we build our world.

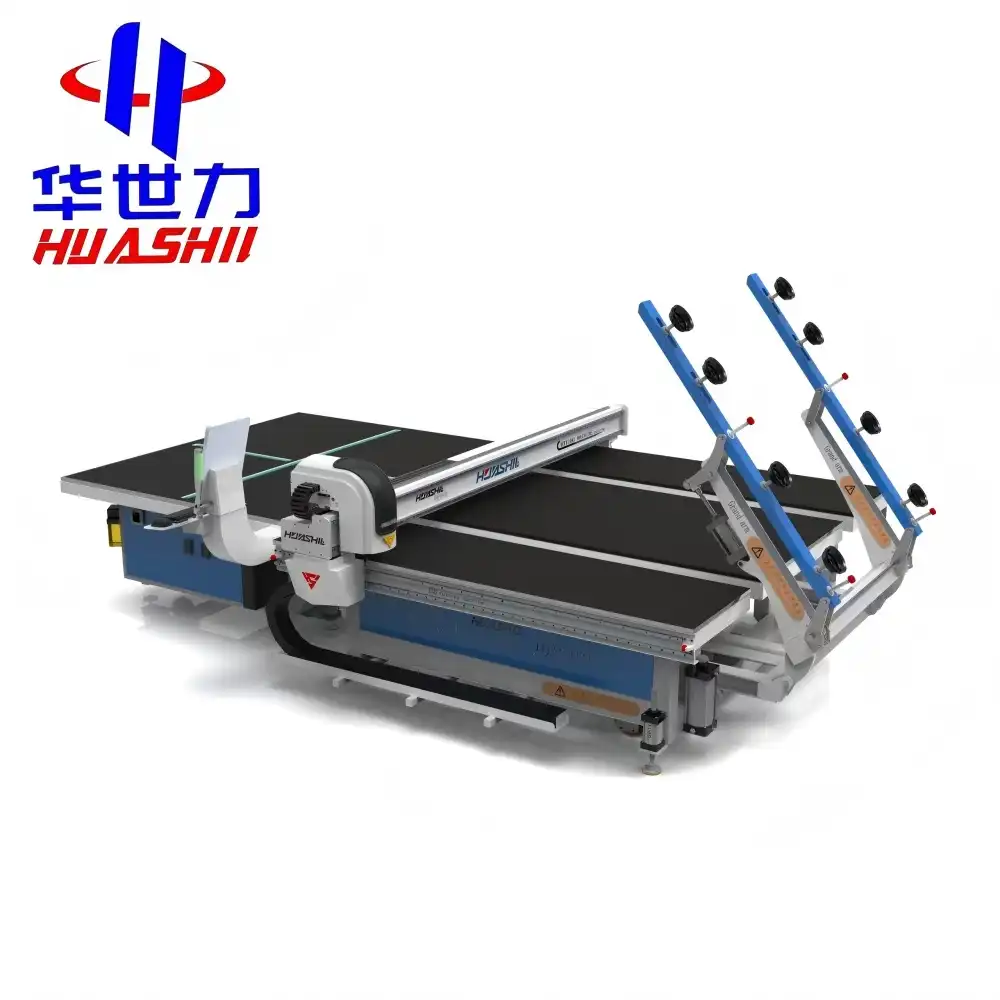

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by construction professionals. Our advanced mobile glass cutting machines are designed to meet the demanding needs of modern construction projects. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer cutting-edge solutions that combine precision, efficiency, and durability. Our commitment to advanced techniques, stable quality, and excellent service has made us a trusted partner for customers worldwide. Experience the future of glass cutting technology and elevate your construction projects to new heights. Contact us today at salescathy@sdhuashil.com to learn how our mobile glass cutting machines can revolutionize your workflow and deliver superior results.

References

1. Johnson, A. (2023). "Advancements in Mobile Glass Cutting Technology for Construction Applications." Journal of Construction Innovation, 45(2), 112-128.

2. Smith, B., & Brown, C. (2022). "The Impact of On-Site Glass Fabrication on Project Efficiency and Cost Reduction." International Journal of Construction Management, 18(4), 301-315.

3. Lee, D., et al. (2023). "Precision and Safety in Custom Balcony Railing Design: A Case Study on Mobile Cutting Machines." Architectural Engineering and Design Management, 19(3), 225-240.

4. Garcia, M. (2022). "Sustainable Practices in Modern Glazing: The Role of Mobile Cutting Technologies." Green Building and Environmental Sustainability, 7(1), 45-60.