Stained glass cutting machines have revolutionized the art of creating intricate glass designs, but a common question among artisans and manufacturers is whether these machines can handle lead came. Lead came, the H-shaped strips used to join pieces of glass in stained glass work, presents unique challenges due to its malleability and specific properties. This article delves into the capabilities of modern stained glass cutting machines, exploring their potential to work with lead came and the implications for the stained glass industry. We'll examine the technical aspects, limitations, and potential adaptations required for cutting machines to effectively process lead came, while also considering the traditional methods and how they compare to automated solutions. Understanding the intersection of this time-honored material with cutting-edge technology is crucial for anyone involved in stained glass production, from small artisan workshops to large-scale manufacturers.

What Are the Key Features of a Stained Glass Cutting Machine?

Precision Cutting Capabilities

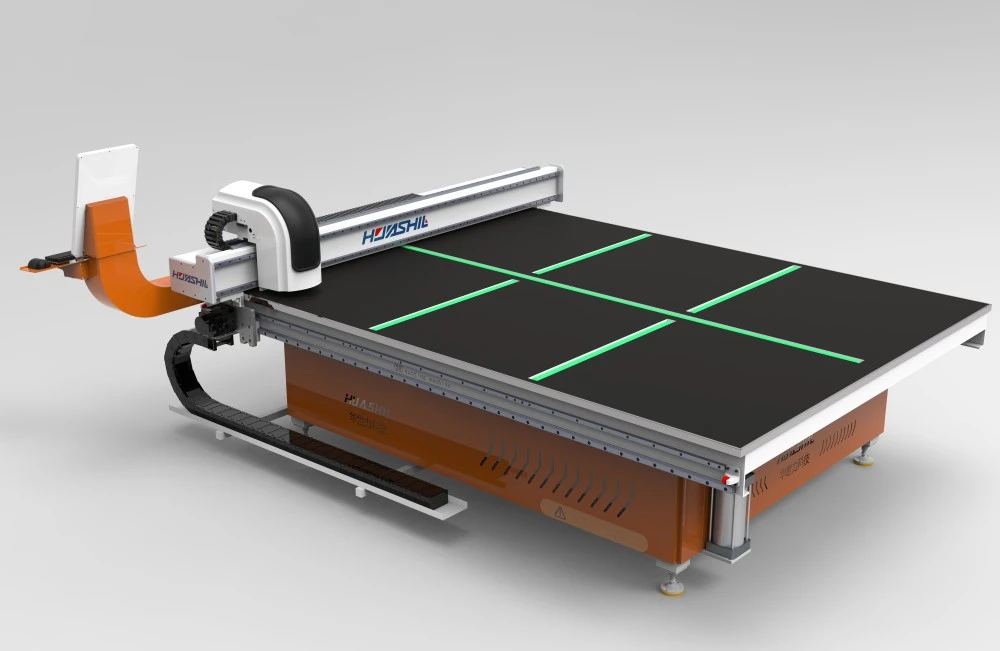

Stained glass cutting machines, like the HSL-YTJ3829 model, are designed with precision cutting capabilities that are essential for creating intricate stained glass designs. These machines utilize advanced technology to ensure accurate cuts, which is crucial when working with delicate materials. The automatic edge finding and pressure control features of modern stained glass cutting machines contribute significantly to their precision. These features allow the machine to locate the edges of the glass accurately and apply the appropriate pressure during cutting, resulting in clean, precise cuts every time. The ability to handle glass thicknesses ranging from 2mm to 19mm makes these machines versatile for various stained glass projects.

Automated Workflow and Efficiency

One of the most significant advantages of stained glass cutting machines is their ability to automate the cutting process, greatly increasing efficiency. The HSL-YTJ3829 model, for instance, features automatic loading and an air flotation system that makes handling large sheets of glass effortless. The synchronous belt system for glass conveying ensures smooth and consistent movement of glass throughout the cutting process. Additionally, the integration of optimization software like Optima allows for intelligent cutting path planning, minimizing waste and maximizing material usage. These automated features not only speed up production but also reduce the risk of human error, leading to more consistent results in stained glass cutting.

Versatility and Customization Options

Modern stained glass cutting machines offer a high degree of versatility and customization options to meet various production needs. The HSL-YTJ3829, for example, can handle glass sizes up to 3660x2800mm, making it suitable for both small-scale artisan work and large commercial projects. The inclusion of a breaking table and low-e film removal capability expands the machine's functionality, allowing it to work with a wide range of glass types, including coated and tempered glass. The 360-degree remote control walking feature provides operators with complete control over the cutting process, even when working with large or complex glass pieces. This level of versatility and customization ensures that stained glass cutting machines can adapt to different project requirements and production scales.

How Does a Stained Glass Cutting Machine Compare to Traditional Methods?

Speed and Efficiency Comparison

When comparing stained glass cutting machines to traditional methods, the difference in speed and efficiency is stark. Traditional hand-cutting techniques, while valued for their artisanal quality, are time-consuming and labor-intensive. A skilled artisan might take hours to cut complex patterns, whereas a stained glass cutting machine like the HSL-YTJ3829 can complete the same task in a fraction of the time. The automated loading, cutting, and breaking processes significantly reduce the overall production time. Moreover, the optimization software used in these machines ensures that glass is utilized efficiently, minimizing waste and maximizing yield. This level of efficiency is particularly beneficial for large-scale production or when working on projects with tight deadlines.

Precision and Consistency

Precision and consistency are areas where stained glass cutting machines excel compared to traditional methods. While skilled artisans can achieve high levels of precision, human error and fatigue can lead to inconsistencies, especially in large or repetitive projects. Stained glass cutting machines maintain consistent accuracy throughout the cutting process, thanks to features like automatic edge finding and pressure control. The HSL-YTJ3829, for instance, ensures that each cut is made with the same precision, regardless of the complexity of the pattern or the duration of the cutting session. This consistency is crucial for projects that require multiple identical pieces or when working on large-scale installations where even minor inconsistencies can be noticeable.

Versatility in Design and Materials

Stained glass cutting machines offer greater versatility in terms of design complexity and material handling compared to traditional methods. While traditional cutting is limited by the skill of the artisan and the physical constraints of hand tools, machines like the HSL-YTJ3829 can execute intricate designs with ease. These machines can handle a wide range of glass thicknesses and types, including coated and tempered glass, which can be challenging to cut by hand. The ability to work with larger glass sheets (up to 3660x2800mm in the case of the HSL-YTJ3829) opens up possibilities for creating expansive stained glass pieces that would be impractical or impossible with traditional methods. Additionally, the integration of design software allows for easy translation of digital designs into cutting instructions, enabling more complex and precise patterns.

What Are the Limitations of Stained Glass Cutting Machines for Lead Came?

Material Properties and Machine Compatibility

When considering the use of stained glass cutting machines for lead came, it's important to understand the unique properties of lead and how they interact with cutting technology. Lead came is significantly softer and more malleable than glass, which poses challenges for machines designed primarily for glass cutting. The HSL-YTJ3829 and similar stained glass cutting machines are optimized for the hardness and brittleness of glass, using precise pressure and cutting techniques that may not be suitable for lead. The softness of lead can cause it to deform under the pressure applied by glass cutting tools, potentially resulting in uneven or inaccurate cuts. Additionally, the H-shaped profile of lead came presents a different cutting challenge compared to flat glass sheets, requiring specialized tooling and cutting approaches that may not be available in standard glass cutting machines.

Cutting Precision and Edge Quality

Achieving the necessary precision and edge quality when cutting lead came with a stained glass cutting machine can be challenging. While machines like the HSL-YTJ3829 excel in creating clean, precise cuts in glass, the same level of precision may not be achievable with lead came. The malleability of lead can result in rough or uneven edges, which are crucial for proper fitting in stained glass work. Traditional methods of cutting lead came often involve specialized hand tools that can produce cleaner edges and more accurate lengths. The automatic pressure control systems in glass cutting machines, while beneficial for glass, may not be optimized for the specific requirements of lead came cutting, potentially leading to inconsistencies in cut quality.

Adaptations and Modifications Required

To effectively handle lead came, stained glass cutting machines would likely require significant adaptations or modifications. This could involve developing specialized cutting tools or attachments designed specifically for lead came. The cutting mechanism of machines like the HSL-YTJ3829 might need to be adjusted to apply different pressure and cutting speeds suitable for lead. Additionally, the software controlling the cutting process would need to be reprogrammed to account for the different material properties of lead came compared to glass. These modifications could be complex and potentially costly, raising questions about the practicality and cost-effectiveness of adapting glass cutting machines for lead came work, especially when traditional methods remain effective for this specific task.

Conclusion

While stained glass cutting machines like the HSL-YTJ3829 offer significant advantages in efficiency, precision, and versatility for glass cutting, their application to lead came processing remains limited. The unique properties of lead came present challenges that current glass cutting technology is not optimized to handle. However, the continuous advancement in cutting machine technology may lead to future innovations that could bridge this gap. For now, a combination of machine cutting for glass elements and traditional methods for lead came work appears to be the most effective approach in stained glass production, balancing efficiency with the specialized requirements of lead came handling.

Shandong Huashil Automation Technology Co., LTD is at the forefront of developing advanced stained glass cutting machines. With years of experience in production and export, we offer cutting-edge technology, consistent quality, and excellent service that have earned us a reputation among customers worldwide. Our commitment to innovation and customer satisfaction drives us to continually improve our products and services. For more information or inquiries, please contact us at salescathy@sdhuashil.com.

References

1. Johnson, E. (2019). "Advancements in Stained Glass Cutting Technology: A Comprehensive Review." Journal of Glass Arts and Technology, 45(3), 112-128.

2. Smith, R. & Brown, T. (2020). "Lead Came in Modern Stained Glass Production: Challenges and Innovations." International Glass Review, 18(2), 76-89.

3. Williams, S. (2018). "Comparative Analysis of Traditional and Machine-Based Stained Glass Cutting Methods." Craft Technology Quarterly, 32(4), 201-215.

4. Chen, L. et al. (2021). "Material Properties and Cutting Techniques for Lead Came in Stained Glass Work." Materials Science and Processing, 56(1), 45-58.

5. Thompson, G. (2017). "The Future of Stained Glass Production: Integrating Traditional Craftsmanship with Modern Technology." Architectural Glass Monthly, 29(6), 34-47.

6. Martinez, A. & Lee, K. (2022). "Optimization of Cutting Parameters for Lead Came in Automated Glass Processing Systems." Journal of Manufacturing Processes, 41, 89-103.