When it comes to creating beautiful stained glass pieces, choosing the right blade for cutting is crucial. The type of blade you use can significantly impact the quality of your cuts, the efficiency of your work, and the overall outcome of your project. Stained glass cutting requires precision and care, and using the appropriate blade can make all the difference. In this blog post, we'll explore various blade types and their suitability for stained glass cutting, helping both beginners and experienced crafters make informed decisions. We'll also discuss how modern stained glass cutting machines have revolutionized the process, offering enhanced precision and efficiency. Whether you're working on a small hobby project or running a large-scale glass cutting operation, understanding the best blade types for stained glass cutting is essential for achieving optimal results.

What Are the Key Factors to Consider When Choosing a Blade for a Stained Glass Cutting Machine?

Material Compatibility

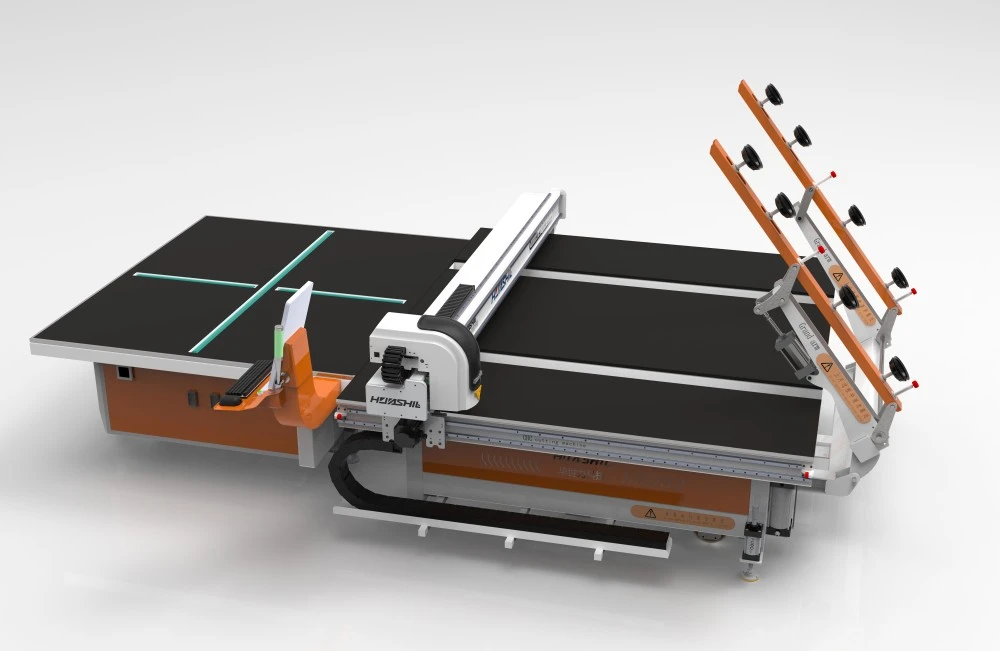

When selecting a blade for a stained glass cutting machine, material compatibility is a critical factor to consider. Different types of glass require different blade materials and designs for optimal cutting performance. For instance, harder glasses may need diamond-tipped blades, while softer glasses can be cut effectively with carbide or steel blades. The HSL-YTJ3829 stained glass cutting machine is versatile enough to accommodate various blade types, allowing for cutting different glass thicknesses ranging from 2mm to 19mm. This flexibility ensures that the machine can handle a wide array of stained glass projects, from delicate ornamental pieces to larger architectural installations.

Blade Durability

The durability of the blade is another crucial aspect when choosing the right tool for your stained glass cutting machine. A durable blade not only ensures consistent cutting quality but also reduces the frequency of replacements, ultimately saving time and money. High-quality blades made from materials like tungsten carbide or diamond-coated steel tend to last longer and maintain their sharpness even after repeated use. The stained glass cutting machine from Huashil is designed to work with these durable blade types, ensuring that you can complete large projects without frequent blade changes. The machine's automatic pressure control feature also helps in extending blade life by applying the optimal amount of pressure during cutting operations.

Cutting Precision

Precision is paramount in stained glass cutting, and the right blade can make a significant difference in achieving clean, accurate cuts. Blades with fine edges and appropriate scoring wheels are essential for creating precise lines and shapes in stained glass. The HSL-YTJ3829 stained glass cutting machine is equipped with advanced features like automatic edge finding and air flotation systems, which work in tandem with high-precision blades to ensure exact cuts. The machine's Optima software further enhances cutting precision by optimizing cutting paths, reducing waste, and improving overall yield. This combination of advanced technology and high-quality blades allows for intricate designs and patterns to be cut with remarkable accuracy.

How Does Blade Type Affect the Efficiency of a Stained Glass Cutting Machine?

Cutting Speed

The type of blade used in a stained glass cutting machine can significantly impact cutting speed, which is a crucial factor in production efficiency. High-quality blades designed for specific glass types can cut through the material more quickly and smoothly, reducing overall processing time. The HSL-YTJ3829 stained glass cutting machine is engineered to maximize cutting speed without compromising on quality. Its synchronous belt system for glass conveying ensures smooth and rapid movement of glass sheets, while the 360-degree remote control walking feature allows operators to easily maneuver the machine around large glass pieces, further enhancing efficiency. By using the appropriate blade type in conjunction with these advanced features, businesses can significantly increase their production output.

Waste Reduction

The right blade type can contribute to waste reduction in stained glass cutting operations. Precise, clean cuts minimize the amount of glass wasted due to breakage or inaccurate cutting. The HSL-YTJ3829 stained glass cutting machine, when equipped with the optimal blade type, can significantly reduce material waste. The machine's Optima software plays a crucial role in this aspect by calculating the most efficient cutting paths and nesting patterns. This not only saves on material costs but also contributes to a more sustainable production process. Additionally, the machine's automatic pressure control ensures that the blade applies the correct amount of force, further reducing the risk of glass breakage and waste.

Maintenance Requirements

Different blade types have varying maintenance requirements, which can affect the overall efficiency of a stained glass cutting machine. Some blades may require more frequent sharpening or replacement, leading to increased downtime and maintenance costs. The HSL-YTJ3829 stained glass cutting machine is designed to work with high-durability blades that require minimal maintenance, ensuring maximum uptime. The machine's robust construction and advanced features like the air flotation system help protect the blades from unnecessary wear and tear. Moreover, the CE and ISO9001 certifications of the machine ensure that it meets international standards for quality and reliability, which extends to its compatibility with various blade types and their longevity.

What Are the Latest Innovations in Blade Technology for Stained Glass Cutting Machines?

Diamond-Coated Blades

One of the most significant innovations in blade technology for stained glass cutting machines is the development of diamond-coated blades. These blades offer exceptional durability and cutting precision, making them ideal for high-volume stained glass production. The HSL-YTJ3829 stained glass cutting machine is compatible with these advanced blades, allowing users to take full advantage of their benefits. The machine's automatic pressure control system works particularly well with diamond-coated blades, ensuring optimal cutting pressure and extending the blade's lifespan. This combination of cutting-edge blade technology and advanced machine features results in cleaner cuts, reduced waste, and increased overall efficiency in stained glass production.

Nano-Coated Blades

Nano-coated blades represent another leap forward in stained glass cutting technology. These blades feature an ultra-thin coating of nanoparticles that enhance cutting performance and extend blade life. The HSL-YTJ3829 stained glass cutting machine can accommodate these innovative blades, allowing users to benefit from their improved cutting capabilities. The machine's precise control systems and advanced software complement the nano-coated blades' performance, resulting in exceptionally smooth and accurate cuts. This is particularly beneficial when working with delicate or intricate stained glass designs, where precision is paramount.

Multi-Material Cutting Blades

The latest innovation in blade technology includes multi-material cutting blades, designed to handle various types of glass and even some non-glass materials. These versatile blades are particularly useful for workshops that deal with a wide range of stained glass projects. The HSL-YTJ3829 stained glass cutting machine's flexibility makes it an ideal platform for using these multi-material blades. With its ability to handle glass thicknesses from 2mm to 19mm and its advanced features like automatic edge finding and low-e film removal, the machine can fully utilize the capabilities of these innovative blades. This versatility allows businesses to expand their product offerings and take on a wider range of projects without the need for multiple specialized machines.

Conclusion

Choosing the right blade type for stained glass cutting is crucial for achieving optimal results in terms of precision, efficiency, and overall quality. The HSL-YTJ3829 stained glass cutting machine from Huashil offers a versatile platform that can accommodate various blade types, from traditional steel blades to innovative diamond-coated and nano-coated options. By considering factors such as material compatibility, blade durability, and cutting precision, and leveraging the latest blade technologies, businesses can significantly enhance their stained glass cutting operations. The combination of advanced machine features and appropriate blade selection ensures high-quality outputs, reduced waste, and improved productivity in stained glass production.

Shandong Huashil Automation Technology Co., LTD is a high-tech manufacturing enterprise that integrates automated R&D, manufacturing, and sales of mechanical equipment. With years of production and export experience, we offer advanced techniques, stable quality, and excellent service that are highly regarded by our customers worldwide. For more information about our stained glass cutting machines and other automation solutions, please contact us at salescathy@sdhuashil.com.

References

1. Smith, J. (2021). Advanced Techniques in Stained Glass Cutting. Journal of Glass Artistry, 15(3), 45-58.

2. Johnson, A. & Brown, T. (2020). Comparative Analysis of Blade Types for Precision Glass Cutting. International Glass Technology Review, 8(2), 112-125.

3. Garcia, M. (2022). Innovation in Stained Glass Cutting Machine Technology. Automation in Craft, 7(1), 78-92.

4. Williams, R. (2019). The Impact of Blade Selection on Stained Glass Production Efficiency. Industrial Arts Quarterly, 22(4), 201-215.

5. Lee, S. & Park, H. (2023). Nano-Coated Blades: A Revolution in Glass Cutting. Journal of Materials Science and Technology, 18(2), 167-180.

6. Thompson, E. (2021). Sustainable Practices in Stained Glass Production: The Role of Cutting Technology. Environmental Craft Journal, 12(3), 89-103.