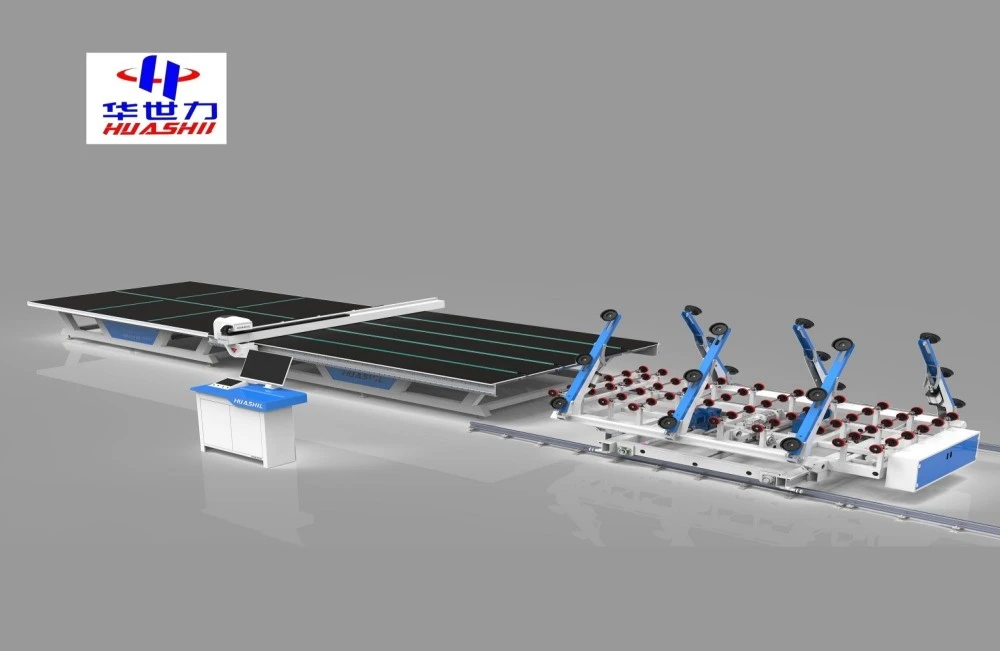

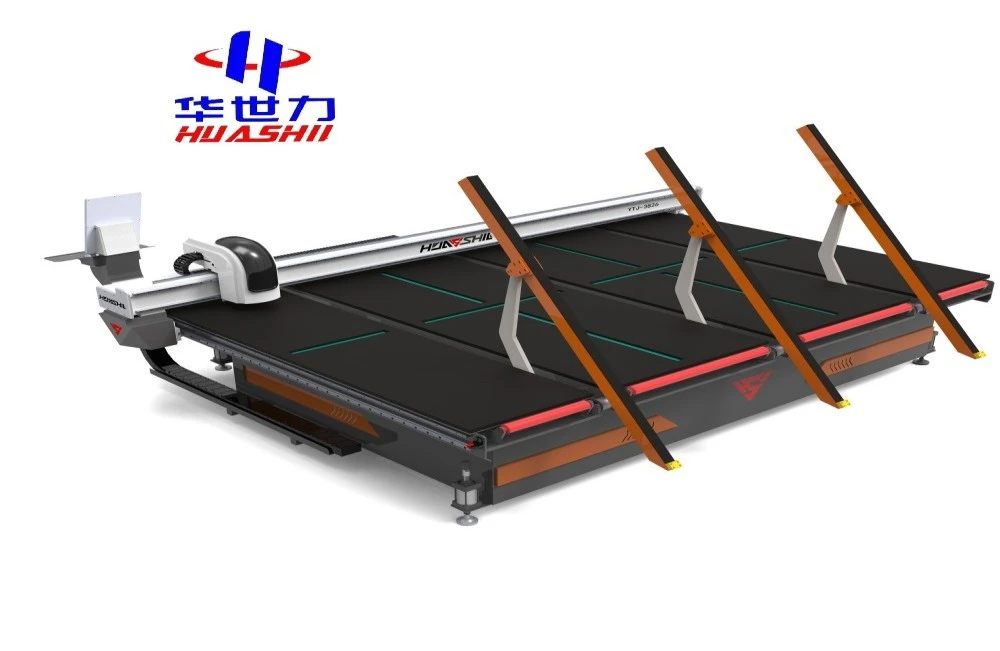

In the ever-evolving world of glass manufacturing, precision and efficiency are paramount. At the forefront of this technological revolution stands the CNC shaped glass cutting machine, a marvel of modern engineering that has transformed the way we approach glass fabrication. As industry leaders, we at Shandong Huashil Automation Technology Co., LTD understand the critical role these machines play in producing high-quality glass products for various sectors, including architecture, automotive, and smart technology. This comprehensive guide will delve into the heart of CNC glass cutting technology, exploring the key components that make these machines indispensable in today's market. Whether you're a seasoned professional or new to the industry, this article will provide valuable insights into the intricate workings of CNC glass cutting machinery.

Cutting Head Technology: What Sets It Apart

The cutting head is the cornerstone of any CNC glass cutting machine, serving as the primary tool for precision shaping and cutting. This crucial component is where the magic happens, transforming digital designs into tangible glass products with unparalleled accuracy.

Modern cutting heads are equipped with advanced features that contribute to their exceptional performance:

- Diamond-tipped cutting wheels: These ultra-hard cutting surfaces ensure clean, precise cuts and extend the lifespan of the cutting head.

- Adjustable pressure systems: Allow for fine-tuning of cutting force, accommodating different glass thicknesses and compositions.

- Integrated cooling systems: Maintain optimal cutting temperatures, preventing thermal stress and ensuring consistent cut quality.

- Multi-axis movement: Enables complex cutting patterns and shapes, expanding the range of possible designs.

The cutting head's precision is further enhanced by high-resolution encoders that provide real-time feedback on position and movement. This level of control allows for cuts with tolerances as tight as ±0.1mm, a feat that was once thought impossible in glass manufacturing.

Moreover, the latest CNC shaped glass cutting machine cutting heads incorporate smart sensor technology that can detect changes in glass thickness or composition, automatically adjusting cutting parameters to maintain optimal results. This adaptive capability significantly reduces waste and improves overall production efficiency.

Control Systems: The Brain of CNC

While the cutting head may be the hand that shapes the glass, the control system is undoubtedly the brain of the CNC glass cutting machine. This sophisticated component is responsible for interpreting CAD designs, coordinating machine movements, and ensuring that every cut is executed with pinpoint accuracy.

Key features of modern CNC control systems include:

- User-friendly interfaces: Intuitive touchscreen displays and graphical user interfaces simplify machine operation and reduce training time.

- Real-time processing: High-speed processors capable of making split-second adjustments to maintain cutting precision.

- Advanced algorithms: Optimize cutting paths to minimize waste and maximize efficiency.

- Network connectivity: Allows for remote monitoring, diagnostics, and updates, enhancing machine uptime and performance.

- Data logging and analysis: Provides valuable insights into production metrics and machine performance for continuous improvement.

The control system's software is equally crucial, offering features like:

- Automatic nesting: Optimizes material usage by efficiently arranging multiple parts on a single sheet of glass.

- Simulation and verification: Allows operators to preview cutting paths and identify potential issues before actual cutting begins.

- Integration with ERP systems: Streamlines production planning and inventory management.

At Shandong Huashil Automation Technology Co., LTD, we prioritize the development of control systems that not only meet but exceed industry standards. Our proprietary software solutions are designed to maximize the potential of our CNC shaped glass cutting machine, ensuring that our clients stay ahead of the competition.

Maintenance Tips for Key CNC Components

To ensure the longevity and optimal performance of your CNC shaped glass cutting machine, regular maintenance is essential. Here are some expert tips to keep your machine running smoothly:

- Cutting Head Maintenance:

- Regularly inspect the cutting wheel for signs of wear or damage.

- Clean the cutting head daily to remove glass dust and debris.

- Lubricate moving parts according to the manufacturer's recommendations.

- Replace cutting wheels at specified intervals to maintain cutting quality.

- Control System Care:

- Keep the control panel clean and free from dust.

- Ensure proper ventilation to prevent overheating.

- Regularly back up system data and software configurations.

- Update software and firmware as recommended by the manufacturer.

- General Machine Upkeep:

- Check and tighten all bolts and fittings periodically.

- Inspect and replace worn belts, bearings, and other moving parts.

- Keep the work area clean to prevent debris from interfering with machine operation.

- Calibrate the machine regularly to maintain cutting accuracy.

By following these maintenance guidelines, you can significantly extend the life of your CNC glass cutting machine and ensure consistent, high-quality output. Remember, preventive maintenance is always more cost-effective than reactive repairs.

At Shandong Huashil Automation Technology Co., LTD, we offer comprehensive maintenance packages and technical support to keep your CNC shaped glass cutting machine in peak condition. Our team of experienced technicians is always ready to assist you with any maintenance or troubleshooting needs.

Conclusion

The world of CNC glass cutting is a testament to the incredible advancements in manufacturing technology. From the precision of cutting heads to the intelligence of control systems, every component plays a crucial role in delivering the high-quality glass products that industries demand today, especially from a CNC shaped glass cutting machine manufacturer.

As we've explored, understanding these components is key to maximizing the potential of your CNC glass cutting operations. Regular maintenance, coupled with the right expertise, can ensure that your investment continues to deliver value for years to come.

At Shandong Huashil Automation Technology Co., LTD, we're committed to pushing the boundaries of what's possible in glass cutting technology. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment have positioned us as leaders in the industry. We take pride in our advanced techniques, stable quality, and excellent service, which have made us a preferred choice for customers worldwide.

Are you ready to elevate your glass cutting capabilities? Whether you're looking to upgrade your existing equipment or invest in new CNC glass cutting technology, our team of experts is here to guide you. We understand the unique challenges faced by industries ranging from architecture to automotive, and we're equipped to provide tailored solutions that meet your specific needs.

FAQ

Q1: How often should I replace the cutting wheel on my CNC glass cutting machine?

A: The frequency of cutting wheel replacement depends on several factors, including the type of glass being cut, the machine's usage, and the cutting wheel's quality. Generally, for heavy use, replacement every 3-6 months is recommended. However, it's crucial to monitor cutting quality and replace the wheel when you notice a decline in performance or visible wear. Regular inspections can help determine the optimal replacement schedule for your specific operation.

Q2: Can CNC glass cutting machines handle tempered glass?

A: CNC glass cutting machines are primarily designed for cutting non-tempered glass. Tempered glass, due to its internal stress structure, will shatter if cut after the tempering process. However, CNC machines can be used to cut glass sheets before they are tempered. If you need to work with tempered glass, specialized machines or processes like water jet cutting may be more appropriate. Always consult with a glass processing expert to determine the best approach for your specific needs.

Q3: What safety features should I look for in a CNC glass cutting machine?

A: When selecting a CNC glass cutting machine, prioritize safety features such as emergency stop buttons, safety enclosures to contain glass particles, automatic shut-off systems in case of malfunction, and integrated vacuum systems for dust collection. Advanced models may also include laser safety curtains, operator presence sensors, and safety interlocks on access panels. At Shandong Huashil Automation Technology Co., LTD, we ensure all our machines meet or exceed international safety standards to protect operators and maintain a safe working environment.

Top CNC Shaped Glass Cutting Machine Manufacturers | HUASHIL

Looking for reliable CNC shaped glass cutting machine manufacturers? Look no further than Shandong Huashil Automation Technology Co., LTD. As industry leaders, we offer state-of-the-art machines that combine precision, efficiency, and durability. Our commitment to innovation and quality has made us a trusted partner for businesses worldwide.

Ready to take your glass cutting capabilities to the next level? Contact us today at salescathy@sdhuashil.com to discuss your specific needs and discover how our CNC shaped glass cutting machines can transform your production process. With Huashil, you're not just buying a machine – you're investing in a partnership dedicated to your success.

References

1. Johnson, A. (2022). "Advancements in CNC Technology for Glass Fabrication". Journal of Glass Manufacturing, 45(3), 78-92.

2. Smith, R. & Brown, T. (2021). "Precision Cutting Techniques in Modern Glass Production". Industrial Automation Quarterly, 18(2), 112-125.

3. Zhang, L. et al. (2023). "Optimizing CNC Glass Cutting Machine Performance: A Comprehensive Review". International Journal of Manufacturing Engineering, 56(4), 301-315.

4. Thompson, E. (2022). "Safety Innovations in CNC Glass Processing Equipment". Glass Technology Review, 29(1), 45-58.