The ability to produce these components with high accuracy using a CNC shaped glass cutting machine not only improves the overall quality of vehicles but also contributes to enhanced safety features. The precision cuts ensure that windshields and windows perform optimally in crash tests and real-world scenarios, protecting passengers and meeting stringent safety regulations.

In today's rapidly evolving industrial landscape, precision and efficiency are paramount. One technology that has revolutionized various sectors is the CNC shaped glass cutting machine. This sophisticated equipment has found its way into numerous industries, transforming the way we manufacture, design, and innovate. Let's explore the diverse applications of this cutting-edge technology and how it's shaping the future of glass processing.

Automotive Sector: Precision Windshield Production

The automotive industry has embraced CNC shaped glass cutting machines with open arms, particularly in the production of windshields and other glass components. These machines offer unparalleled precision, ensuring that each piece of glass meets the exact specifications required for modern vehicles.

In windshield production, the CNC technology allows for:

- Intricate cuts for complex curvatures

- Precise sizing for perfect fitment

- Smooth edges that enhance safety

- Consistent quality across large production runs

Moreover, as vehicles become more technologically advanced, the demand for specialized glass components increases. CNC machines can create precise cutouts for sensors, cameras, and other smart features integrated into modern car windshields.

Architectural Marvels: CNC in Modern Buildings

The architectural industry has witnessed a renaissance in glass design, thanks to CNC glass cutting equipment. From towering skyscrapers to avant-garde residential spaces, shaped glass has become a hallmark of contemporary architecture.

CNC machines enable architects and designers to push the boundaries of what's possible with glass, creating:

- Custom-shaped facades that defy conventional building designs

- Intricate patterns and textures on glass surfaces

- Precisely cut openings for ventilation and lighting

- Unique artistic installations that blend form and function

The precision offered by CNC shaped glass cutting machine technology ensures that each piece of glass fits perfectly within the overall structure, minimizing gaps and enhancing energy efficiency. This level of accuracy is crucial in creating buildings that are not only aesthetically pleasing but also environmentally sustainable.

Furthermore, the versatility of the CNC shaped glass cutting machine allows for the production of glass elements in various thicknesses and sizes, catering to the diverse needs of modern architecture. From expansive curtain walls to delicate interior partitions, CNC-cut glass is transforming the way we experience built environments.

Electronics: How CNC Shapes Your Devices?

The electronics industry relies heavily on precision components, and glass plays a crucial role in many devices we use daily. CNC shaped glass cutting machines are instrumental in creating the sleek, functional screens and protective covers for smartphones, tablets, and other electronic gadgets.

In the realm of consumer electronics, CNC technology facilitates:

- Production of durable, scratch-resistant screen protectors

- Precise cutouts for camera lenses, speakers, and buttons

- Creation of curved glass for innovative display designs

- Manufacturing of glass backings for wireless charging capabilities

The ability to cut glass with microscopic precision ensures that each component fits perfectly within the compact designs of modern devices. This level of accuracy is essential for maintaining the water-resistant properties of many smartphones and wearables.

Beyond consumer electronics, CNC shaped glass cutting machine supplier plays a vital role in the production of specialized glass components for industrial and scientific equipment. From laboratory instruments to advanced display technologies, the precision offered by CNC machines is indispensable in pushing the boundaries of electronic innovation.

Furniture and Interior Design: Elevating Spaces with Glass

The furniture and interior design industries have embraced CNC glass cutting technology to create stunning, functional pieces that elevate living and working spaces. From elegant glass tabletops to stylish room dividers, CNC machines enable designers to bring their most ambitious visions to life.

In the realm of furniture design, CNC-cut glass offers:

- Custom-shaped tabletops with smooth, polished edges

- Intricate patterns and designs for decorative glass panels

- Precise cutouts for integrated lighting or hardware

- Seamless glass shelving units with perfect fitment

The precision of the CNC shaped glass cutting machine allows for the creation of glass elements that seamlessly integrate with other materials such as wood or metal, resulting in unique, eye-catching furniture pieces. This technology has opened up new possibilities for designers, enabling them to experiment with form and function in ways previously unimaginable.

In interior design, CNC-cut glass is used to create stunning features such as:

- Customized shower enclosures and bathroom partitions

- Artistic glass wall installations and room dividers

- Precision-cut mirror designs for decorative purposes

- Glass staircase treads and balustrades

The ability to create these bespoke glass elements with such precision not only enhances the aesthetic appeal of interior spaces but also contributes to their functionality and durability.

Aerospace: Pushing the Boundaries of Glass Technology

The aerospace industry demands the highest levels of precision and quality in its components, and glass is no exception. CNC glass cutting machines play a crucial role in manufacturing various glass elements for aircraft and spacecraft.

In aerospace applications, CNC technology is used for:

- Crafting cockpit windows with complex curvatures

- Producing high-strength glass panels for aircraft cabins

- Creating precision glass components for avionics displays

- Manufacturing specialized glass for satellite and space vehicle windows

The extreme conditions faced by aerospace glass components require unparalleled precision in their manufacture. The CNC shaped glass cutting machine ensures that each piece meets the stringent safety and performance standards of the industry, withstanding high pressures, extreme temperatures, and potential impacts.

Moreover, as the aerospace industry continues to innovate, CNC glass cutting technology enables the development of new glass-based solutions. From smart windows that can adjust their tint to reduce glare and heat to glass-embedded sensors for enhanced flight data collection, the possibilities are expanding rapidly.

FAQ

Q1: What are the key advantages of using a CNC shaped glass cutting machine?

A: CNC shaped glass cutting machines offer several significant advantages:

- Precision: They provide extremely accurate cuts, ensuring consistent quality.

- Efficiency: Automated processes increase production speed and reduce waste.

- Versatility: These machines can handle a wide range of glass thicknesses and types.

- Complex Designs: They can execute intricate patterns and shapes that would be difficult or impossible to achieve manually.

- Repeatability: Once programmed, the machine can reproduce the same cuts with high consistency.

- Safety: Automated cutting reduces the risk of injuries associated with manual glass cutting.

Q2: How does a CNC shaped glass cutting machine contribute to sustainability in manufacturing?

A: CNC shaped glass cutting machines contribute to sustainability in several ways:

- Reduced Waste: Precise cutting minimizes material waste.

- Energy Efficiency: Modern CNC machines are designed to be more energy-efficient than traditional cutting methods.

- Longevity of Products: The precision of CNC-cut glass components often results in longer-lasting products, reducing the need for replacements.

- Optimized Material Usage: Advanced software allows for optimal nesting of cuts, maximizing the use of each glass sheet.

- Reduced Transportation: The ability to produce custom components on-site can reduce the need for shipping pre-fabricated parts.

- Improved Recyclability: Precise cutting can make it easier to separate and recycle different types of glass at the end of a product's life.

Innovative Glass Solutions for Every Industry | HUASHIL

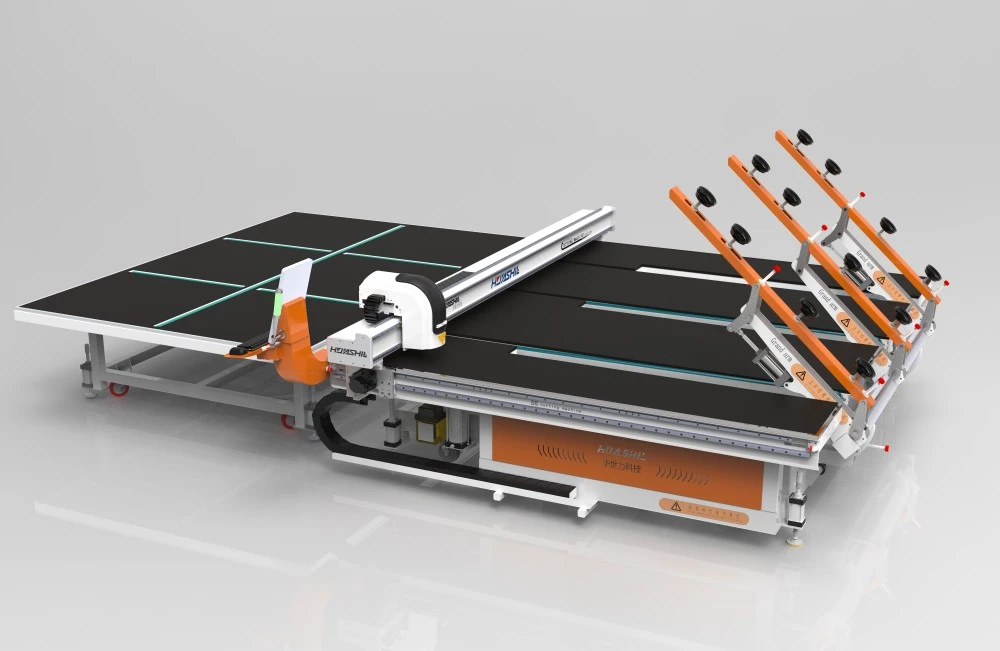

As we've explored, CNC shaped glass cutting machines have revolutionized numerous industries, from automotive and architecture to electronics and aerospace. The precision, efficiency, and versatility offered by these machines have opened up new possibilities in design and manufacturing, pushing the boundaries of what's possible with glass.

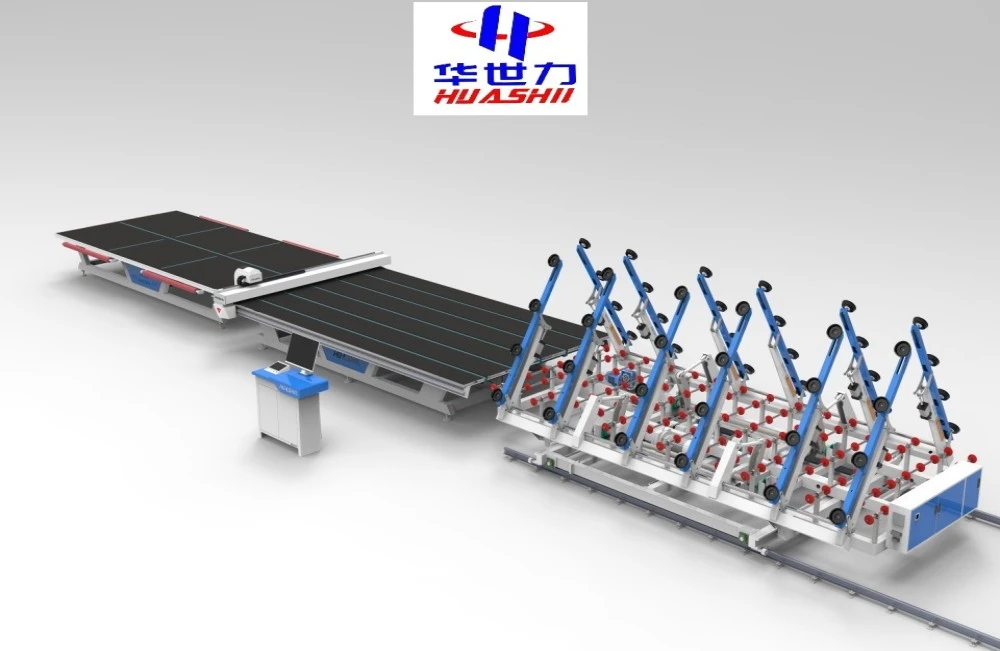

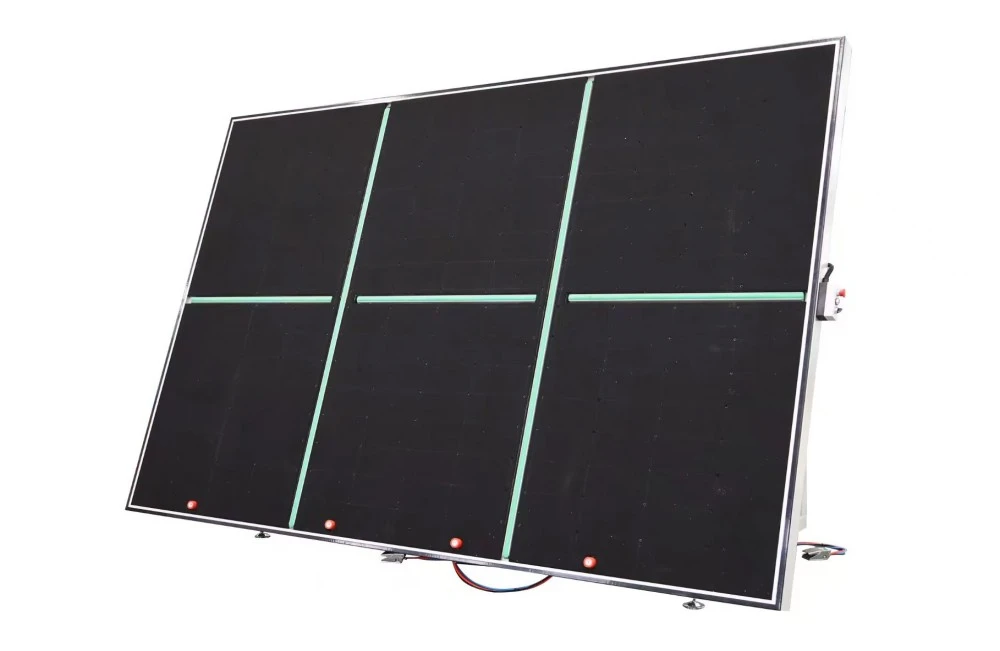

At Shandong Huashil Automation Technology Co., LTD, we understand the transformative power of CNC technology in glass processing. Our state-of-the-art CNC shaped glass cutting machines are designed to meet the diverse needs of various industries, ensuring precision, quality, and innovation in every cut.

Whether you're looking to enhance your production capabilities, explore new design possibilities, or improve the quality of your glass components, we're here to help. Our team of experts can guide you in selecting the right CNC solution for your specific needs, ensuring that you stay ahead in your industry.

Ready to elevate your glass processing capabilities? Contact us today at salescathy@sdhuashil.com to learn more about our CNC shaped glass cutting machines and how they can transform your operations. Let's shape the future of glass together!

References

1. Johnson, A. (2023). "The Evolution of CNC Technology in Modern Manufacturing". Industrial Engineering Quarterly.

2. Smith, B. & Lee, C. (2022). "Glass in Architecture: Innovations and Applications". Journal of Architectural Design.

3. Patel, R. (2023). "Advancements in Automotive Glass Technology". Automotive Engineering Review.

4. Zhang, L. et al. (2022). "Precision Glass Cutting in Electronics: Challenges and Solutions". IEEE Transactions on Manufacturing Technology.