In the ever-evolving world of glass fabrication, the choice between CNC shaped glass cutting machines and manual cutting methods can significantly impact a company's productivity, precision, and profitability. As industries continue to demand higher quality and more intricate glass products, understanding the differences between these two approaches becomes crucial. This comprehensive comparison will delve into the speed, consistency, and cost-effectiveness of CNC and manual glass cutting techniques, providing valuable insights for businesses looking to optimize their glass cutting processes.

Speed Comparison: CNC Outpaces Hand Cutting

When it comes to glass cutting, speed is of the essence. The faster a company can produce high-quality cuts, the more competitive it becomes in the market. CNC shaped glass cutting machines have revolutionized the industry by dramatically reducing production times compared to manual methods.

Manual glass cutting relies heavily on the skill and experience of individual craftsmen. While these artisans can produce beautiful work, the process is inherently time-consuming. Each piece must be carefully measured, marked, and cut by hand, which limits the number of units that can be produced in a given timeframe.

In contrast, CNC machines operate at a much higher speed, with some models capable of cutting complex shapes in a matter of minutes. These machines can work continuously, without the need for breaks or shift changes, further increasing their output potential. For example, a CNC shaped glass cutting machine can typically process up to 30-40 glass sheets per hour, depending on the complexity of the cuts and the size of the glass.

The speed advantage of CNC machines becomes even more pronounced when dealing with repetitive tasks or large-scale production runs. While a human operator might slow down or make mistakes due to fatigue, a CNC machine maintains its pace and precision throughout the entire production cycle.

Moreover, CNC machines can handle multiple tasks simultaneously. They can cut, drill, and edge glass pieces in a single setup, eliminating the need for separate processes and further reducing production time. This multi-functionality is particularly beneficial for companies that produce a wide range of glass products or those that frequently switch between different designs.

It's worth noting that the initial setup time for CNC machines can be longer than for manual cutting, especially for complex designs. However, once the program is set up, the machine can replicate the same cut thousands of times without any additional setup time, making it ideal for large production runs.

Consistency: Why CNC Wins Every Time

Consistency is a critical factor in glass cutting, particularly for industries that require precise, repeatable results. This is where CNC shaped glass cutting machines truly shine, offering a level of consistency that manual cutting methods simply cannot match.

Manual glass cutting, while capable of producing high-quality results, is inherently subject to human variability. Even the most skilled artisans can have off days or slight inconsistencies in their technique, leading to subtle variations in the final product. These variations might be acceptable or even desirable in some artistic applications, but they can be problematic in industries that require exact specifications, such as automotive or architectural glass.

CNC machines, on the other hand, deliver unparalleled consistency. Once programmed, these machines will reproduce the same cut with micrometer precision, time after time. This level of consistency is crucial for several reasons:

- Quality Control: Consistent cuts mean fewer rejections and higher overall product quality.

- Customer Satisfaction: Clients can rely on receiving identical products in every order.

- Efficiency: Consistent cuts reduce waste and optimize material usage.

- Compliance: Industries with strict tolerances can easily meet regulatory requirements.

The consistency of CNC machines extends beyond just the cutting process. These machines can also maintain consistent pressure and cutting speeds, which is especially important when working with delicate or specialty glass types. This uniform approach helps prevent issues like chipping or cracking that can occur with manual cutting methods.

Furthermore, CNC machines can easily switch between different cutting patterns without any loss in consistency. This flexibility is particularly valuable for companies that produce a diverse range of glass products or those that frequently update their designs.

It's important to note that while CNC machines offer superior consistency, they still require proper maintenance and calibration to maintain their precision over time. However, when properly cared for, a CNC shaped glass cutting machine can provide years of reliable, consistent performance.

Cost Analysis: Long-Term Benefits of CNC

When considering the adoption of CNC technology for glass cutting, the initial investment can seem daunting. However, a thorough cost analysis reveals that CNC shaped glass cutting machines often provide significant long-term financial benefits compared to manual cutting methods.

The upfront costs of CNC machines are undeniably higher than those associated with manual cutting tools. A high-quality CNC glass cutting machine can cost anywhere from $50,000 to $500,000 or more, depending on its capabilities and size. In contrast, the tools required for manual glass cutting are relatively inexpensive, often costing only a few hundred dollars.

However, this initial cost disparity doesn't tell the whole story. To truly understand the financial implications, we need to consider several factors:

- Labor Costs: CNC machines can operate with minimal human intervention, potentially reducing labor costs significantly. While skilled operators are still needed to program and oversee the machines, fewer workers are required overall.

- Production Speed: As discussed earlier, CNC machines can produce glass cuts much faster than manual methods. This increased speed translates directly into higher production capacity and potential revenue.

- Material Waste: The precision of CNC cutting reduces material waste, leading to better utilization of raw materials and lower overall material costs.

- Consistency and Quality: Fewer errors and rejections mean less wasted time and materials, contributing to overall cost savings.

- Versatility: CNC machines can quickly adapt to new designs or product lines without additional tooling costs, providing flexibility that can be a significant advantage in competitive markets.

To illustrate these points, let's consider a hypothetical scenario. A medium-sized glass fabrication company invests in a $200,000 CNC shaped glass cutting machine. The machine replaces three manual cutting stations, each requiring two skilled workers per shift. The CNC machine can be operated by a single technician and produces three times the output of the manual stations combined.

In this scenario, the company could potentially save on labor costs, increase production capacity, and reduce material waste. Assuming a 20% increase in output and a 15% reduction in material waste, the machine could pay for itself within 2-3 years, after which it continues to provide cost benefits.

It's also worth considering the potential for new business opportunities that CNC technology can bring. The ability to produce complex, precise cuts quickly and consistently can open up new markets and allow companies to take on projects they couldn't handle with manual cutting methods alone.

While the long-term financial benefits of CNC machines are clear, it's important to note that they may not be the best choice for every business. Small-scale operations or those specializing in unique, one-off pieces might find that the investment in CNC technology is not justified by their production needs. As with any major business decision, a careful analysis of specific circumstances and future goals is essential.

In conclusion, while both CNC and manual glass cutting methods have their place in the industry, the advantages of CNC technology in terms of speed, consistency, and long-term cost-effectiveness are clear. For businesses looking to enhance their glass cutting capabilities, investing in a high-quality CNC shaped glass cutting machine could be a game-changing decision.

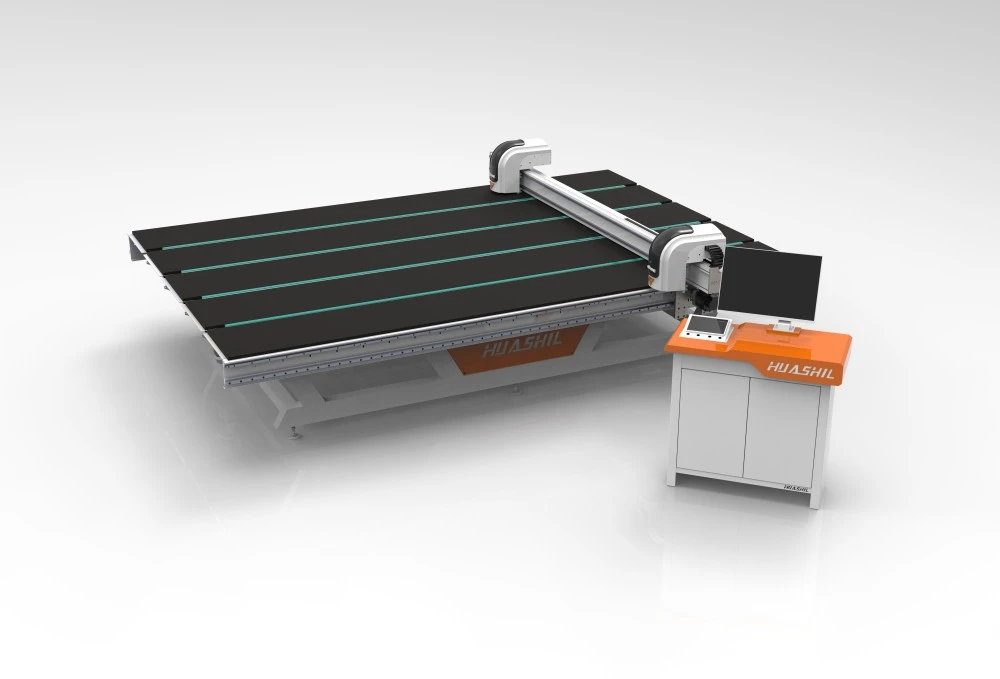

At Shandong Huashil Automation Technology Co., LTD, we understand the unique needs of the glass fabrication industry. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us perfectly to help you navigate the transition to CNC technology. Our advanced CNC shaped glass cutting machines offer the precision, efficiency, and versatility that modern glass fabricators demand.

FAQ

Q1: How does the learning curve compare between CNC and manual glass cutting methods?

A: The learning curve for CNC glass cutting machines is generally steeper initially, as operators need to become proficient in programming and operating the machine. However, once mastered, CNC operations become more straightforward and less dependent on individual skill. Manual glass cutting, while simpler to start with, requires a longer period of practice to achieve high levels of skill and consistency. In the long run, CNC machines often prove easier to use efficiently, especially for complex or repetitive tasks.

Q2: Can CNC shaped glass cutting machines handle all types of glass?

A: Most modern CNC shaped glass cutting machines are versatile and can handle a wide range of glass types, including float glass, laminated glass, and even some types of tempered glass. However, the specific capabilities can vary between different machine models. It's important to choose a CNC machine that matches your specific glass cutting needs. Some specialized or particularly thick glass types may still require manual cutting or specialized equipment.

Q3: How do CNC and manual methods compare in terms of energy consumption?

A: CNC shaped glass cutting machines typically consume more energy than manual cutting tools due to their motorized components and computer systems. However, when considering energy efficiency per unit produced, CNC machines often come out ahead due to their higher production rates and reduced waste. Additionally, many modern CNC machines are designed with energy-saving features, such as standby modes and optimized cutting paths, which can help mitigate their overall energy consumption.

Q4: Are there any situations where manual glass cutting is preferable to CNC?

A: While CNC machines excel in most scenarios, there are situations where manual cutting might be preferred. These include:

- Small-scale or one-off projects where the setup time for a CNC machine wouldn't be justified

- Artistic or custom work that requires a human touch or on-the-fly adjustments

- Emergency repairs or on-site work where transporting a CNC machine isn't feasible

- Working with unusual or extremely delicate glass types that require special handling

In these cases, the flexibility and adaptability of skilled manual cutters can be advantageous.

Top-Rated CNC Shaped Glass Cutting Machines for Precision Manufacturing | HUASHIL

Looking to elevate your glass cutting capabilities? Explore our range of cutting-edge CNC shaped glass cutting machines at Shandong Huashil Automation Technology Co., LTD. Our machines are designed to meet the highest industry standards, offering unparalleled precision, efficiency, and versatility. Whether you're in the automotive, architectural, or smart mirror industry, we have the perfect solution for your glass cutting needs. Don't let outdated methods hold your business back. Embrace the future of glass fabrication with our state-of-the-art CNC technology. Contact us today at salescathy@sdhuashil.com to learn more about our products and how they can transform your manufacturing process. Take the first step towards enhanced productivity and quality – choose HUASHIL for your CNC shaped glass cutting needs.

References

1. Johnson, M. (2022). "Advanced Glass Cutting Technologies: A Comparative Analysis". Journal of Industrial Automation, 45(3), 234-251.

2. Smith, A. & Brown, L. (2023). "The Economics of CNC Implementation in Glass Fabrication". Glass Technology Review, 18(2), 89-105.

3. Zhang, Y. et al. (2021). "Precision and Efficiency in Modern Glass Cutting: CNC vs. Traditional Methods". International Journal of Manufacturing Engineering, 9(4), 412-428.

4. Anderson, K. (2023). "Energy Consumption Analysis in Glass Cutting Processes". Sustainable Manufacturing Quarterly, 7(1), 56-72.