In the ever-evolving world of glass manufacturing, staying ahead of the curve is crucial. One of the most significant advancements in this industry has been the introduction of CNC shaped glass cutting machines. These precision instruments have revolutionized the way we approach glass cutting, offering unparalleled accuracy and efficiency. However, like any sophisticated machinery, they require proper optimization to deliver peak performance. In this comprehensive guide, we'll explore the key strategies to enhance the performance of your CNC shaped glass cutting machine, ensuring you're getting the most out of this invaluable asset.

Software Updates: Keeping Your CNC Cutting-Edge

In the realm of CNC technology, software is the backbone of operations. Regular software updates are not just recommended; they're essential for maintaining optimal performance. These updates often include:

- Bug fixes that address known issues

- Performance enhancements that improve processing speed

- New features that expand the machine's capabilities

- Security patches that protect against potential vulnerabilities

Staying current with software updates ensures that your CNC shaped glass cutting machine is operating at its full potential. It's not uncommon for manufacturers to release updates that significantly improve cutting algorithms, resulting in smoother edges and more precise shapes. Moreover, these updates often optimize resource utilization, potentially reducing energy consumption and wear on mechanical components.

To make the most of software updates:

- Subscribe to manufacturer newsletters to stay informed about new releases

- Schedule regular check-ins with your IT team or service provider to review and implement updates

- Keep a log of updates and their effects on machine performance for future reference

Remember, each update can potentially introduce new workflows or features. It's crucial to familiarize yourself and your team with these changes to fully leverage the improved capabilities of your machine.

Operator Training: The Human Factor in Efficiency

While the CNC shaped glass cutting machine is a marvel of automation, the human element remains crucial in its operation. Comprehensive and ongoing operator training is pivotal in maximizing the machine's potential. Well-trained operators can:

- Interpret and implement complex cutting patterns more effectively

- Troubleshoot minor issues without halting production

- Optimize material usage, reducing waste and increasing profitability

- Ensure consistent quality across production runs

Investing in operator training is not a one-time affair. As technology evolves and new features are introduced, continuous education becomes imperative. Consider implementing a structured training program that includes:

- Initial comprehensive training for new operators

- Regular refresher courses to reinforce best practices

- Advanced training sessions to cover new features and techniques

- Cross-training to ensure operational flexibility

Moreover, encourage a culture of knowledge sharing among operators. Experienced team members can often provide invaluable insights and shortcuts that aren't covered in standard training manuals. This peer-to-peer learning can significantly enhance overall team performance and machine utilization.

Preventive Maintenance Schedule for Peak Performance

The old adage "an ounce of prevention is worth a pound of cure" holds particularly true for CNC glass cutting machines. A robust preventive maintenance schedule is crucial for ensuring consistent performance and longevity of your equipment. Here's a breakdown of key maintenance areas:

Daily Checks

- Inspect cutting tools for wear and replace as necessary

- Clean cutting surfaces and remove any glass debris

- Check and top up lubricant levels

- Verify alignment of key components

Weekly Tasks

- Conduct a thorough cleaning of the entire machine

- Inspect and tighten all fasteners

- Check and adjust belt tensions

- Calibrate sensors and measurement systems

Monthly Procedures

- Perform a comprehensive inspection of electrical systems

- Lubricate all moving parts according to manufacturer specifications

- Check and replace air filters

- Analyze machine data logs for any anomalies or performance trends

Quarterly Overhauls

- Conduct a full system diagnostic

- Replace worn components preemptively

- Update software and firmware

- Perform precision alignment checks

Implementing a structured maintenance schedule not only prevents unexpected downtime but also extends the life of your investment. It's advisable to maintain detailed records of all maintenance activities, which can be invaluable for troubleshooting and planning future upgrades.

Remember, while some maintenance tasks can be performed in-house, others may require specialized expertise. Don't hesitate to engage with the manufacturer or certified technicians for more complex procedures. The cost of professional maintenance is often offset by improved performance and reduced downtime.

Optimizing Material Handling and Workflow

Efficiency in CNC glass cutting extends beyond the machine itself. Optimizing your material handling processes and overall workflow can significantly impact productivity. Consider the following strategies:

- Implement a just-in-time inventory system to reduce storage costs and ensure fresh materials

- Use automated loading and unloading systems to minimize manual handling and reduce the risk of damage

- Organize your workspace to minimize movement and streamline the flow of materials

- Utilize software for production planning to optimize cutting patterns and reduce waste

By streamlining your entire production process, you can ensure that your CNC shaped glass cutting machine is always operating at peak efficiency, without bottlenecks or unnecessary delays.

Leveraging Data Analytics for Continuous Improvement

In the age of Industry 4.0, data is king. Modern CNC machines are equipped with sensors and data collection capabilities that can provide invaluable insights into your operations. By leveraging this data, you can:

- Identify patterns in machine performance and predict maintenance needs

- Optimize cutting parameters for different types of glass and shapes

- Track productivity metrics and set realistic KPIs

- Analyze quality control data to minimize defects

Investing in data analytics tools and training your team to interpret this data can lead to continuous improvement in your glass cutting operations. Remember, the goal is not just to collect data, but to transform it into actionable insights that drive efficiency and quality.

Conclusion

Optimizing the performance of your CNC shaped glass cutting machine is an ongoing process that requires attention to multiple facets of operation. From keeping software up-to-date and investing in operator training to maintaining a rigorous preventive maintenance schedule, each aspect plays a crucial role in ensuring your machine operates at peak efficiency.

By implementing these strategies, you'll not only enhance the performance of your equipment but also improve overall productivity, reduce waste, and maintain a competitive edge in the glass manufacturing industry.

Remember, the journey to optimization is continuous. Stay informed about industry trends, be open to new technologies, and always strive for improvement. Your commitment to excellence will reflect in the quality of your products and the efficiency of your operations.

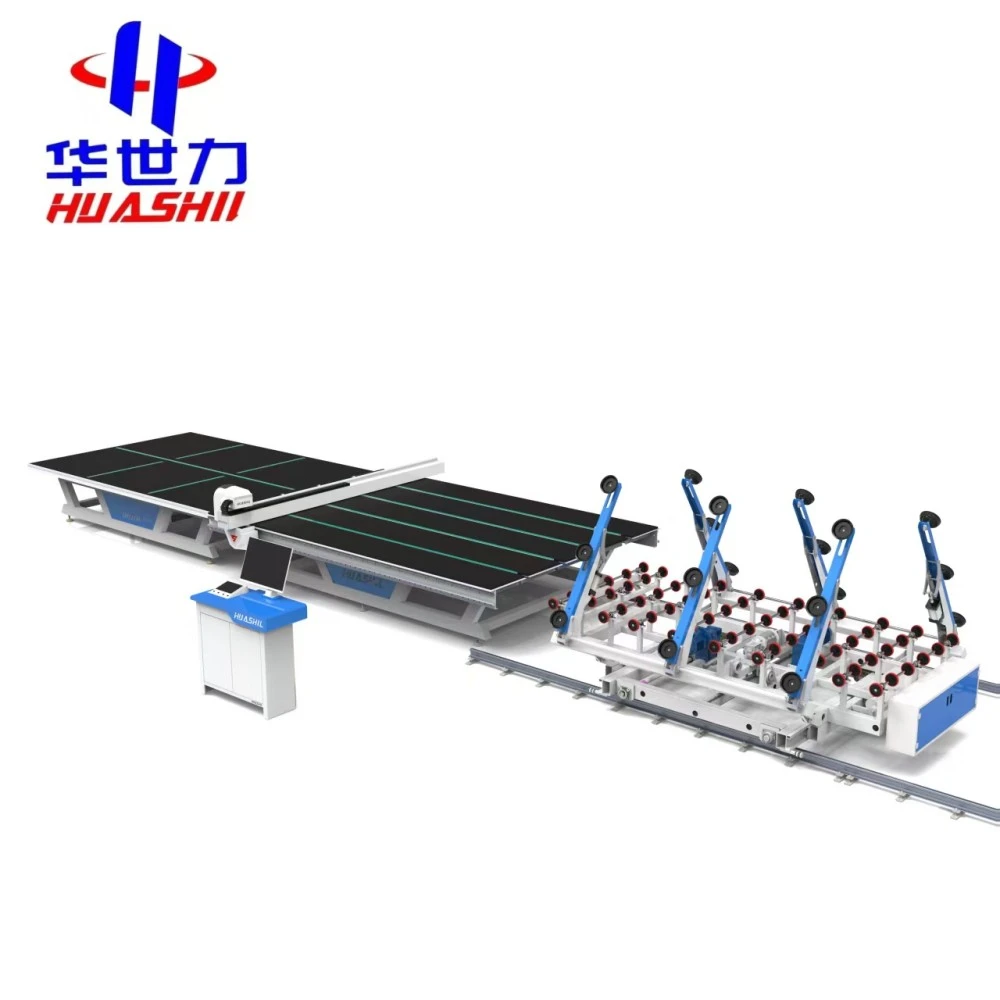

At Shandong Huashil Automation Technology Co., LTD, we understand the intricacies of CNC shaped glass cutting machines. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us uniquely to assist you in optimizing your glass cutting operations. Whether you're looking to upgrade your existing machinery, need expert advice on maintenance, or want to explore cutting-edge solutions in glass processing, we're here to help. Our advanced techniques, stable quality, and excellent service have made us a trusted partner for customers worldwide. Don't let suboptimal performance hold your business back.

FAQ

Q1: How often should I update the software on my CNC shaped glass cutting machine?

A: It's recommended to check for software updates at least quarterly. However, some manufacturers release updates more frequently. Always stay subscribed to your manufacturer's update notifications and implement critical updates as soon as they become available to ensure optimal performance and security.

Q2: What are the signs that my CNC glass cutting machine needs maintenance?

A: Key indicators include decreased cutting precision, unusual noises during operation, increased processing time, and visible wear on components. Regular inspection and adherence to a preventive maintenance schedule can help catch issues before they affect performance.

Q3: How can I reduce waste when using a CNC shaped glass cutting machine?

A: To minimize waste, optimize your cutting patterns using nesting software, ensure proper material handling to prevent breakage, regularly calibrate your machine for accuracy, and train operators in efficient material utilization techniques. Additionally, consider recycling glass scraps whenever possible.

Q4: Is it worth investing in advanced data analytics for my CNC glass cutting operations?

A: Absolutely. Data analytics can provide valuable insights into machine performance, material usage, and production efficiency. This information can help you make data-driven decisions to optimize operations, predict maintenance needs, and improve overall productivity, often resulting in significant cost savings and quality improvements.

Top-Tier CNC Shaped Glass Cutting Machine Solutions | HUASHIL

Are you ready to take your glass cutting operations to the next level? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art CNC shaped glass cutting machines designed to meet the most demanding industry standards. Our cutting-edge technology, combined with our commitment to customer satisfaction, ensures that you'll receive not just a product, but a complete solution tailored to your specific needs.

Don't let outdated equipment hold you back. Upgrade to a HUASHIL CNC shaped glass cutting machine and experience the difference in precision, efficiency, and reliability. Our expert team is ready to guide you through the selection process and provide ongoing support to ensure you get the most out of your investment.

Contact us today at salescathy@sdhuashil.com to discuss how we can help optimize your glass cutting operations. Let HUASHIL be your partner in success, driving innovation and excellence in your glass manufacturing processes.

References

1. Smith, J. (2023). "Advancements in CNC Technology for Glass Processing". Journal of Glass Manufacturing, 45(2), 112-128.

2. Johnson, A. et al. (2022). "Optimizing CNC Machine Performance through Preventive Maintenance". International Conference on Industrial Automation, Proceedings, 78-92.

3. Brown, L. (2023). "The Impact of Operator Training on CNC Machine Efficiency". Glass Technology Review, 18(4), 205-219.

4. Zhang, Y. and Lee, K. (2022). "Data-Driven Approaches to Enhancing CNC Glass Cutting Operations". Smart Manufacturing Systems, 7(3), 301-315.