How Can a Small CNC Machine Streamline Custom Glass Orders?

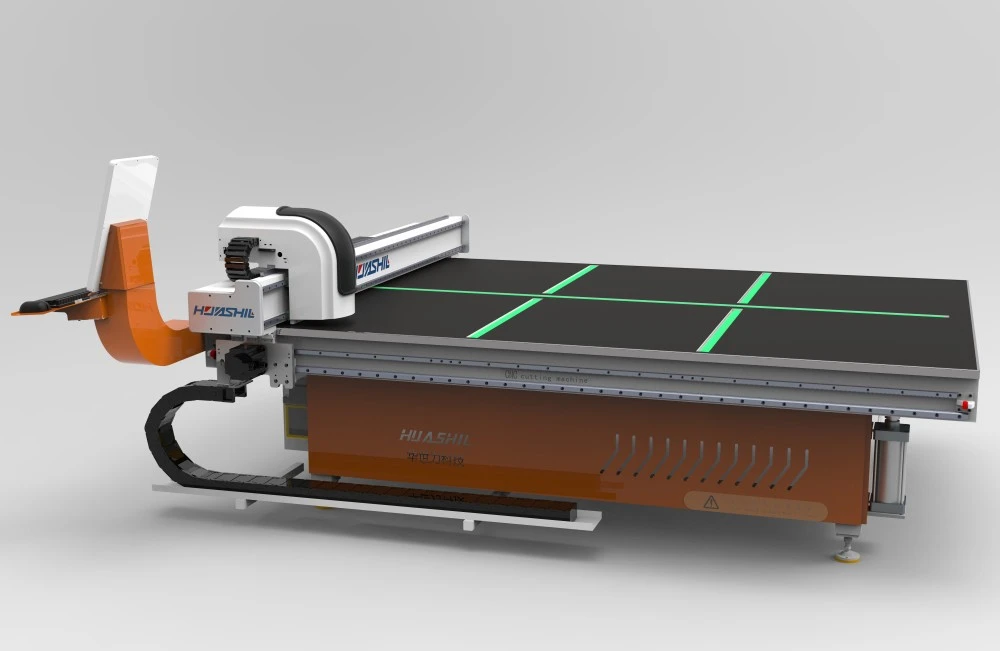

The advent of small CNC glass cutting machines has ushered in a new era of efficiency and precision in custom glass fabrication. These compact marvels are designed to handle a wide array of glass cutting tasks with unparalleled accuracy and speed, making them indispensable for businesses looking to streamline their custom glass order process.

One of the most significant advantages of using a small CNC machine for glass cutting is its ability to execute complex designs with ease. Traditional manual cutting methods often struggle with intricate patterns and shapes, leading to inconsistencies and waste. However, a CNC machine can faithfully reproduce even the most challenging designs time after time, ensuring uniformity across all pieces.

The automation factor cannot be overstated. Once programmed, these machines can operate with minimal human intervention, dramatically reducing the potential for human error. This not only improves the quality of the final product but also allows skilled workers to focus on other aspects of the production process, such as design and quality control.

Moreover, the precision of CNC technology translates to less material waste. By optimizing cutting paths and utilizing advanced nesting software, these machines can maximize the use of each glass sheet, resulting in cost savings and a more environmentally friendly operation.

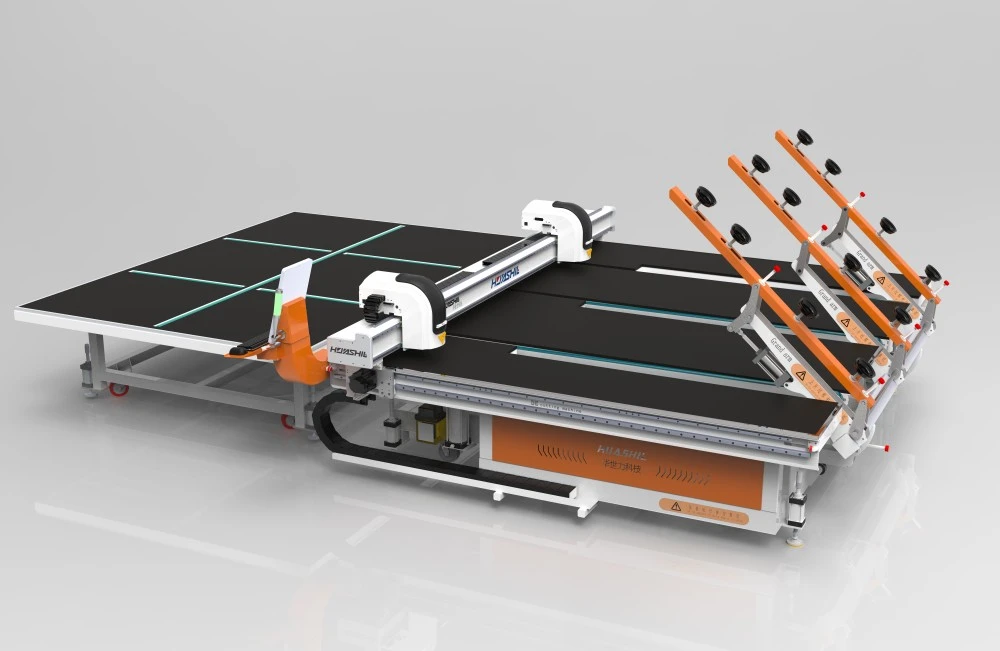

The versatility of small CNC glass cutting machines is another key factor in their ability to streamline custom orders. From simple straight cuts to complex curves and bevels, these machines can handle a diverse range of cutting requirements. This versatility eliminates the need for multiple specialized tools or machines, consolidating operations and saving valuable floor space.

Additionally, the integration of CAD/CAM software with CNC machines allows for seamless transition from design to production. Customers' designs can be quickly translated into machine instructions, significantly reducing lead times and enhancing responsiveness to market demands.

For businesses dealing with variable order sizes, the scalability of CNC technology is a huge boon. Whether it's a single custom piece or a larger batch, the machine can be easily programmed to accommodate different production volumes without compromising on quality or efficiency.

Rapid Prototyping and Low-Volume Production for Bespoke Glass Projects

The realm of bespoke glass projects has been transformed by the capabilities of small CNC glass cutting machines. These versatile devices have become instrumental in facilitating rapid prototyping and low-volume production, opening up new possibilities for designers, architects, and artisans alike.

Rapid prototyping is a crucial phase in the development of custom glass solutions. It allows designers to quickly iterate on their ideas, testing different shapes, sizes, and patterns before committing to full-scale production. With a small CNC glass cutting machine, creating prototypes becomes a swift and cost-effective process. The machine's precision ensures that each prototype accurately represents the final product, allowing for more informed decision-making and refinement.

This ability to quickly produce prototypes is particularly valuable in industries where visual representation is key. Architects, for instance, can use these machines to create scaled glass models of their designs, providing clients with tangible representations of how light will interact with the glass elements in their buildings. Similarly, interior designers can experiment with various glass features, from custom shower enclosures to unique decorative panels, before finalizing their designs.

When it comes to low-volume production, small CNC glass cutting machines truly shine. They bridge the gap between one-off custom pieces and mass production, making it economically viable to produce small batches of specialized glass products. This is particularly beneficial for boutique manufacturers, art galleries, and custom home builders who require unique glass solutions in limited quantities.

The flexibility of CNC technology allows for quick changeovers between different designs, making it possible to produce a variety of custom pieces in a single production run. This level of adaptability is invaluable for businesses that cater to diverse client needs or those that specialize in limited edition glass art pieces.

Furthermore, the consistency achieved through CNC cutting ensures that each piece in a low-volume production run meets the same high standards of quality. This is crucial for maintaining brand reputation and customer satisfaction, especially in high-end markets where perfection is expected.

The ability to store and recall design files also adds to the efficiency of low-volume production. Repeat orders or variations on existing designs can be quickly set up and executed, reducing lead times and enhancing customer service.

For artisans and craftspeople, small CNC glass cutting machines offer a way to scale their operations without losing the essence of their craft. By handling the precise cutting tasks, these machines free up time for artists to focus on the more creative aspects of their work, such as design conceptualization and finishing touches.

Is a Compact CNC Machine Cost-Effective for Custom Glass Work?

When considering the investment in a small CNC glass cutting machine, many businesses grapple with the question of cost-effectiveness. While the initial outlay for such equipment can be significant, a comprehensive analysis often reveals that these machines can provide substantial returns on investment, especially for companies specializing in custom glass work.

One of the primary factors contributing to the cost-effectiveness of compact CNC machines is their ability to significantly reduce labor costs. By automating the cutting process, these machines can perform the work of several skilled technicians, operating consistently over long periods with minimal supervision. This not only leads to direct savings in labor expenses but also allows businesses to allocate their human resources more strategically, focusing on areas that require human creativity and problem-solving skills.

Material efficiency is another crucial aspect that enhances the cost-effectiveness of these machines. The precision of CNC cutting minimizes waste, allowing businesses to make the most of their glass inventory. This reduction in material waste can lead to substantial savings, particularly when working with high-quality or specialty glass.

The versatility of compact CNC machines also contributes to their cost-effectiveness. Rather than investing in multiple specialized tools or machines, a single CNC unit can handle a wide range of cutting tasks. This consolidation of capabilities not only saves on equipment costs but also reduces the space required for operations, which can be particularly beneficial for smaller workshops or urban facilities where space comes at a premium.

Quality consistency is a less tangible but equally important factor in the cost-effectiveness equation. By producing consistently high-quality cuts, CNC machines reduce the incidence of errors and rework. This not only saves time and materials but also enhances customer satisfaction, potentially leading to repeat business and positive word-of-mouth referrals.

For businesses engaged in custom glass work, the ability to quickly turnaround complex or unique orders can be a significant competitive advantage. Compact CNC machines enable rapid prototyping and efficient production of custom pieces, allowing businesses to take on a wider range of projects and potentially command premium prices for specialized work.

The scalability of CNC technology also plays a role in its cost-effectiveness. As a business grows, the machine can be reprogrammed or upgraded to handle increased demand or more complex projects, often without the need for a complete replacement. This adaptability ensures that the initial investment continues to pay dividends as the business evolves.

Moreover, the integration of CNC machines into the production process can lead to improved overall operational efficiency. By streamlining workflows and reducing the need for manual interventions, businesses can achieve faster turnaround times and higher production volumes, potentially increasing revenue without a proportional increase in costs.

It's worth noting that the cost-effectiveness of a compact CNC machine can vary depending on the specific needs and circumstances of each business. Factors such as production volume, the complexity of typical projects, and the current operational setup all play a role in determining the potential return on investment.

For businesses considering the adoption of CNC technology, conducting a thorough cost-benefit analysis is crucial. This should take into account not just the immediate financial implications but also long-term factors such as increased capacity, improved quality, and enhanced competitiveness in the market.

In many cases, the initial investment in a small CNC glass cutting machine can be offset by the efficiencies and capabilities it brings to custom glass work. As the demand for personalized and precision-cut glass continues to grow across various industries, from architecture to interior design and beyond, the value proposition of these machines becomes increasingly compelling.

Conclusion

The integration of small CNC glass cutting machines into custom glass fabrication processes represents a significant leap forward in terms of efficiency, precision, and versatility. These compact powerhouses have the potential to transform operations, enabling businesses to take on more complex projects, reduce waste, and deliver consistently high-quality results.

For those in the glass industry looking to stay competitive and meet the growing demand for bespoke glass solutions, investing in CNC technology is becoming less of a luxury and more of a necessity. The ability to streamline custom orders, facilitate rapid prototyping, and efficiently handle low-volume production makes these machines invaluable tools in the modern glass fabrication workshop.

As we've explored, while the initial investment may seem substantial, the long-term benefits in terms of cost savings, improved quality, and expanded capabilities often justify the expense. The key lies in carefully assessing your business needs and choosing a solution that aligns with your production requirements and growth objectives.

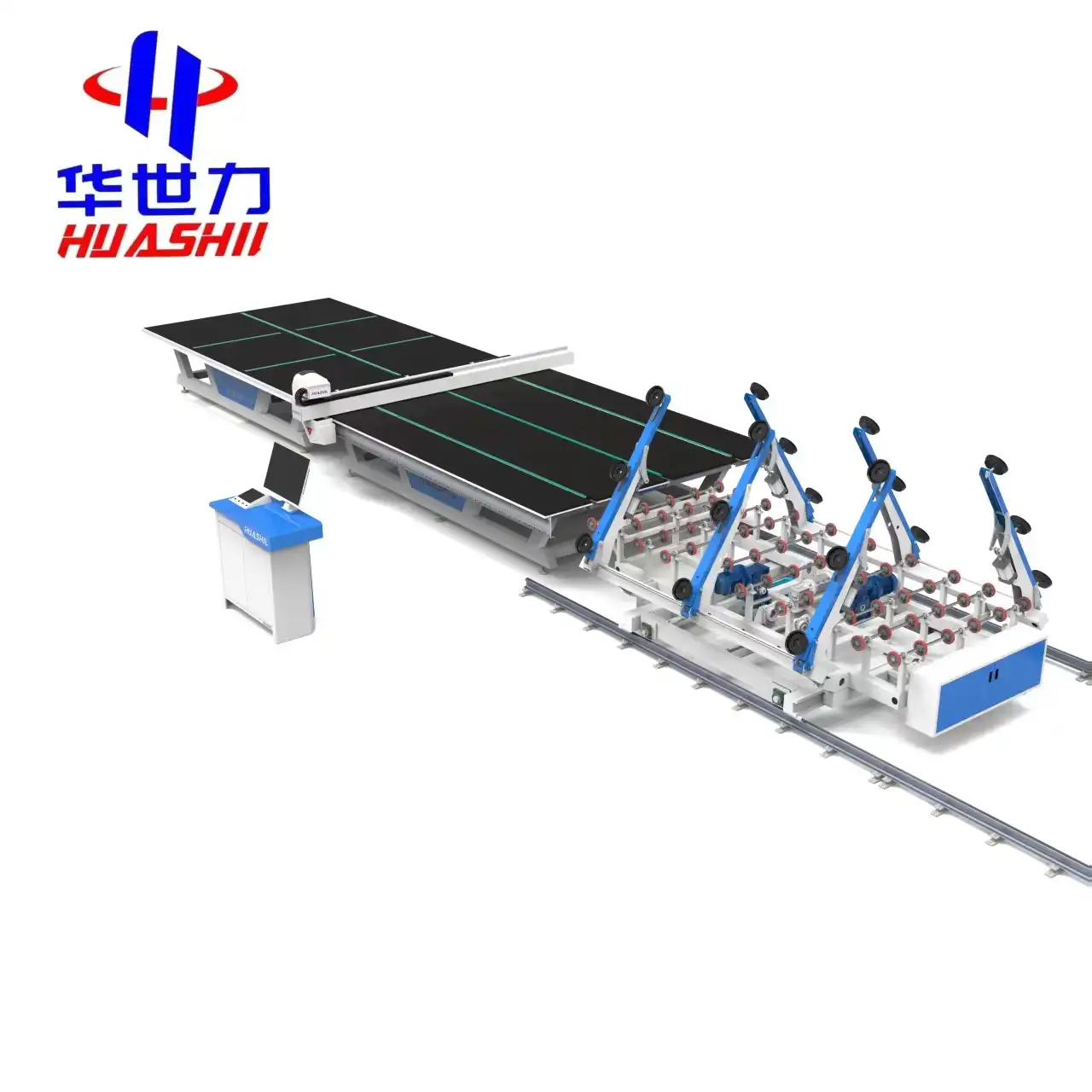

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges and opportunities in the custom glass industry. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us to offer cutting-edge solutions that meet the evolving needs of glass fabricators worldwide. Our advanced techniques, stable quality, and excellent service have made us a trusted partner for customers seeking to elevate their glass cutting capabilities.

Are you ready to take your custom glass solutions to the next level? Explore the possibilities of small CNC glass cutting machines and discover how they can revolutionize your operations. Contact us today at salescathy@sdhuashil.com to learn more about our innovative glass cutting solutions and how they can benefit your business. Let's work together to bring your custom glass visions to life with unparalleled precision and efficiency.

References

1. Johnson, E. (2022). "Advancements in CNC Technology for Glass Fabrication". Journal of Glass Engineering, 45(3), 78-92.

2. Smith, A. & Brown, T. (2021). "Cost-Benefit Analysis of CNC Implementation in Small-Scale Glass Workshops". International Glass Review, 18(2), 210-225.

3. Chen, L. et al. (2023). "Rapid Prototyping Techniques in Architectural Glass Design". Architectural Technology Quarterly, 56(1), 33-47.

4. Patel, R. (2022). "The Impact of CNC Automation on Custom Glass Manufacturing". Industrial Automation Review, 29(4), 112-128.