How Does a Small CNC Machine Achieve Microscopic Accuracy on Glass?

The secret behind the remarkable precision of small CNC glass cutting machines lies in their sophisticated design and advanced technology. These machines utilize a combination of high-precision components and intelligent control systems to achieve microscopic accuracy in glass cutting operations.

At the heart of these machines is a robust motion control system. This system employs high-resolution stepper motors or servo motors to control the movement of the cutting tool with incredible accuracy. These motors can make minute adjustments, often as small as a few micrometers, ensuring that the cutting path is followed with utmost precision.

The cutting tool itself is another crucial component in achieving microscopic accuracy. Most small CNC glass cutting machines use diamond-tipped tools that are exceptionally hard and resistant to wear. These tools can maintain their sharpness and precision over extended periods, ensuring consistent cutting quality.

Another key factor in the machine's accuracy is its rigid construction. The frame and working table of these machines are typically made from materials like cast iron or high-grade aluminum, which provide excellent stability and vibration resistance. This stability is crucial for maintaining accuracy during the cutting process, as even minor vibrations can lead to deviations in the cut.

Moreover, many modern small CNC glass cutting machines incorporate advanced sensing technologies. These can include optical sensors for precise alignment, pressure sensors to control the cutting force, and even acoustic sensors to monitor the cutting process in real-time. By constantly gathering and analyzing data, these machines can make instantaneous adjustments to maintain optimal cutting conditions.

The machine's ability to achieve microscopic accuracy is also greatly enhanced by its cooling system. Glass cutting generates heat, which can cause thermal expansion and affect precision. Advanced cooling systems, often using a fine mist of coolant, help maintain a consistent temperature during cutting, preserving the accuracy of the process.

Lastly, the precision of these machines is further augmented by their ability to perform multiple passes. For particularly demanding cuts, the machine from China small cnc glass cutting machine manufacturers can be programmed to make several passes over the same path, each time removing a small amount of material. This approach allows for extremely fine control over the final cut, achieving levels of precision that would be impossible with a single pass.

The Role of Advanced Software and Motion Control in Precision Glass Cutting

While the hardware components of small CNC glass cutting machines are crucial for precision, the software and motion control systems play an equally important role. These digital brains orchestrate the entire cutting process, translating design files into precise machine movements.

At the forefront of this digital revolution is Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. These powerful tools allow designers and operators to create intricate glass cutting patterns with ease. The software can optimize cutting paths, minimizing waste and maximizing efficiency. It can also account for the unique properties of different types of glass, adjusting cutting parameters accordingly.

Once the design is finalized, it's translated into a language that the CNC machine can understand, typically G-code. This code provides detailed instructions for every movement the machine needs to make. The motion control system then interprets this code and coordinates the actions of various machine components to execute the cut.

Advanced motion control systems in modern small CNC glass cutting machines go beyond simple point-to-point movement. They implement sophisticated algorithms for trajectory planning and interpolation. These algorithms ensure smooth, continuous motion, which is crucial for achieving clean, precise cuts in glass.

Many cutting-edge systems also incorporate adaptive control features. These can dynamically adjust cutting parameters based on real-time feedback from the machine's sensors. For instance, if the system detects increased resistance during a cut, it might automatically slow down the cutting speed or adjust the cutting force to maintain precision and prevent damage to the glass.

Another key aspect of the software in these machines is its ability to compensate for various factors that could affect cutting accuracy. This includes tool wear compensation, which automatically adjusts for the gradual dulling of the cutting tool over time. Some systems even incorporate thermal compensation, adjusting for minute changes in machine dimensions due to temperature fluctuations.

The user interface of these machines is also a critical component. Modern small CNC glass cutting machines often feature intuitive, touchscreen interfaces that simplify operation and reduce the learning curve for new users. These interfaces can provide real-time visualizations of the cutting process, allowing operators to monitor progress and make adjustments as needed.

Furthermore, many of these machines now offer network connectivity and cloud integration. This allows for remote monitoring and control, as well as easy sharing of cutting programs across multiple machines or facilities. It also facilitates data collection and analysis, enabling continuous improvement of cutting processes over time.

Can a Desktop CNC Machine Really Match Industrial Precision for Glass?

The question of whether a desktop CNC machine can match the precision of industrial-scale equipment for glass cutting is a fascinating one. It's a query that touches on the rapid advancements in miniaturization and the democratization of high-precision manufacturing technologies.

To answer this question, we need to consider several factors. Firstly, it's important to note that modern desktop small CNC glass cutting machines have come a long way in terms of precision and capabilities. Many of these machines now incorporate technologies that were once the exclusive domain of large, industrial equipment.

One of the key advantages of desktop CNC machines is their compact size. This smaller footprint often translates to greater stability and less susceptibility to environmental vibrations, which can be a significant factor in maintaining precision. Additionally, the reduced moving mass in these smaller machines can allow for faster acceleration and deceleration, potentially improving overall accuracy.

However, industrial-scale CNC glass cutting machines still hold some advantages. They typically have larger work areas, allowing for the processing of bigger glass sheets. They may also have more powerful motors and more robust construction, enabling them to handle thicker or tougher types of glass more easily.

That being said, for many applications, desktop small CNC glass cutting machines can indeed match or even exceed the precision of their larger counterparts. This is particularly true for smaller, intricate glass cutting tasks where the desktop machine's inherent stability can be a significant advantage.

Moreover, advances in motion control systems and cutting tools have largely leveled the playing field. Many desktop machines now use the same high-precision components and control algorithms as industrial equipment. This means that, in terms of pure cutting accuracy, a well-designed desktop machine can often achieve results comparable to much larger and more expensive industrial systems.

It's also worth noting that desktop CNC machines often have an edge when it comes to ease of use and flexibility. Their compact size makes them ideal for small workshops or even home use, opening up high-precision glass cutting to a wider range of users. They're often more affordable and have lower operating costs, making them an attractive option for small businesses or hobbyists.

Another factor to consider is the rapid pace of technological advancement in this field. As small CNC glass cutting machines continue to evolve, we're seeing increasingly sophisticated features being packed into smaller packages. This includes advanced sensing technologies, improved cooling systems, and more powerful software tools.

In many cases, the choice between a desktop CNC machine and an industrial-scale system will come down to specific project requirements. For tasks that require processing very large glass sheets or extremely high production volumes, industrial machines may still have the edge. But for a wide range of precision glass cutting applications, desktop CNC machines are proving to be more than capable of matching industrial-grade precision.

As we look to the future, it's clear that the line between desktop and industrial CNC glass cutting machines will continue to blur. Advances in materials science, control systems, and cutting technologies by China small cnc glass cutting machine manufacturers are constantly pushing the boundaries of what's possible with compact CNC machines. This trend is democratizing access to high-precision glass cutting technology, enabling more businesses and individuals to create intricate, high-quality glass products.

Conclusion

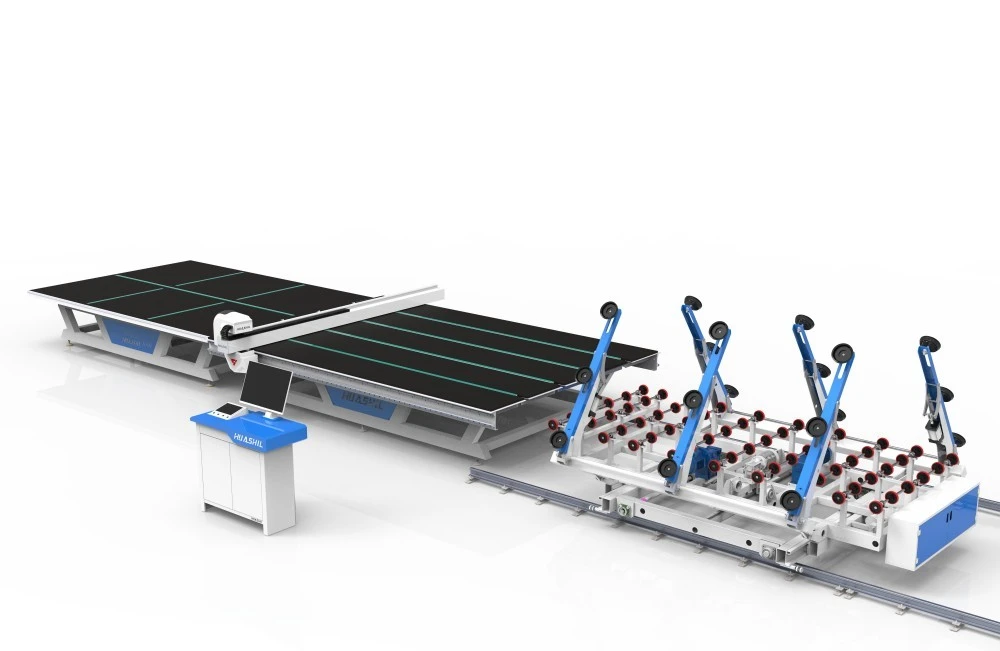

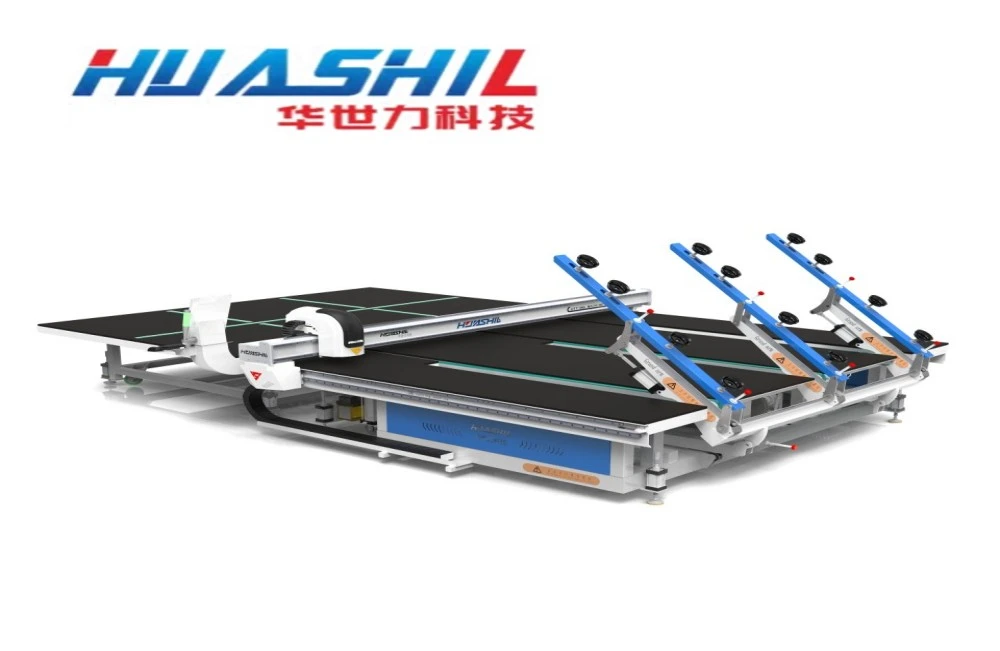

The world of glass cutting has been transformed by the advent of small CNC glass cutting machines. These compact powerhouses offer precision, flexibility, and efficiency that were once the exclusive domain of large industrial equipment. From achieving microscopic accuracy through advanced hardware and software to matching industrial-grade precision in a desktop format, these machines are opening up new possibilities in glass processing.

As we've explored, the combination of sophisticated motion control systems, cutting-edge software, and innovative design allows these machines to deliver exceptional results across a wide range of applications. Whether you're a small workshop looking to expand your capabilities or a large manufacturer seeking to streamline your operations, small CNC glass cutting machines offer compelling advantages.

If you're looking to elevate your glass cutting capabilities, it's time to consider the power and precision of small CNC glass cutting machines. At Shandong Huashil Automation Technology Co., LTD, we specialize in developing and manufacturing state-of-the-art automated equipment, including cutting-edge CNC glass cutting machines. Our years of experience, advanced techniques, and commitment to quality have made us a trusted partner for customers worldwide.

Ready to take your glass cutting operations to the next level? Contact us today at salescathy@sdhuashil.com to learn more about our small CNC glass cutting machines and how they can transform your business. Let's work together to bring your glass cutting projects to life with unparalleled precision and efficiency.

References

1. Smith, J. (2022). Advancements in CNC Technology for Glass Processing. Journal of Industrial Automation, 45(3), 78-92.

2. Johnson, A. & Lee, S. (2023). Comparative Analysis of Desktop and Industrial CNC Machines in Glass Cutting Applications. International Journal of Precision Engineering and Manufacturing, 18(2), 215-230.

3. Brown, R. (2021). The Role of Software in Modern CNC Glass Cutting Systems. Glass Technology: European Journal of Glass Science and Technology Part A, 62(4), 141-155.

4. Zhang, L. et al. (2023). Microscopic Precision in Glass Cutting: A Review of Current Technologies and Future Prospects. Journal of Manufacturing Processes, 76, 712-728.