From Geometric to Organic: Pattern Possibilities

The realm of glass cutting has expanded far beyond simple straight lines and basic shapes. Today's cutting-edge glass cutting line machines are capable of producing an astonishing array of patterns, limited only by the imagination of the designer.

Geometric patterns, once the mainstay of glass design, have evolved to new levels of complexity. These machines can effortlessly create intricate tessellations, fractals, and optical illusions that captivate the eye and transform ordinary glass into extraordinary art. The precision of these cuts is so fine that even the most complex mathematical patterns can be reproduced with stunning accuracy.

But it's not just about straight lines and angles. Modern glass cutting technology has made significant strides in organic pattern creation. Flowing curves, nature-inspired shapes, and freeform designs that once seemed impossible to achieve in glass are now readily achievable. From delicate leaf patterns to sweeping wave-like forms, these machines can replicate the fluidity of nature with remarkable fidelity.

The versatility extends to textural patterns as well. By manipulating cutting depth and angle, these machines can create surfaces that not only catch the eye but also engage the sense of touch. Raised patterns, subtle embossing, and even three-dimensional effects can be achieved, adding a new dimension to glass design—capabilities made possible by advanced equipment from a China glass cutting line machine factory.

This expanded palette of possibilities has revolutionized industries far beyond traditional glassmaking. Architectural firms are using these patterns to create stunning facades and interior elements that play with light in innovative ways. The automotive industry has embraced this technology to produce windshields and windows that are not just functional but also contribute to the overall aesthetic of the vehicle.

Even the world of art has been transformed. Artists who work with glass now have a tool that can translate their most ambitious visions into reality. The line between functional glass and art piece has blurred, with everyday objects like tabletops, shower enclosures, and even smartphone screens becoming canvases for intricate designs.

Custom Programming: Bringing Designs to Life

At the heart of the glass cutting line machine's versatility lies its sophisticated programming capabilities. These machines are not mere automatons repetitively performing the same task. Instead, they are highly intelligent systems that can be customized to execute a wide range of cutting patterns with precision and consistency.

The programming process begins with design software that allows creators to draft their patterns digitally. These designs can range from simple vector graphics to complex 3D models. The software then translates these designs into a language that the machine can understand – a series of coordinates and cutting instructions.

What sets modern glass cutting machines apart is their ability to interpret and execute these instructions with incredible accuracy. Advanced sensors and control systems ensure that each cut is made with micrometric precision, regardless of the complexity of the pattern. This level of accuracy is crucial, especially when creating patterns that rely on perfect symmetry or intricate interlocking designs.

The customization doesn't stop at the pattern itself. These machines can be programmed to adjust cutting speed, pressure, and even the angle of the cutting tool. This flexibility allows for optimization based on the specific type of glass being used, its thickness, and the desired finish of the final product.

Moreover, many China glass cutting line machine factories are incorporating artificial intelligence and machine learning into their systems. These advanced features allow the machines to learn from each cut, continuously improving their performance and even suggesting optimizations to the programmed patterns.

The implications of this programmability are far-reaching. For manufacturers, it means the ability to quickly switch between different designs without the need for lengthy retooling processes. This agility is crucial in today's fast-paced market where customization and short production runs are increasingly the norm.

For designers, this technology opens up a world of possibilities. Ideas that were once considered too complex or time-consuming to implement can now be realized with ease. The iterative process of design has been accelerated, allowing for rapid prototyping and refinement of ideas.

The customization capabilities extend beyond just cutting patterns. Many modern glass cutting lines integrate additional processes like edge polishing, drilling, and even printing. This integration allows for the creation of complete, ready-to-use glass components in a single production line, further streamlining the manufacturing process.

Market Demand: Unique Glass Products Trend

The advent of highly customizable glass cutting line machines has coincided with a significant shift in market demand. Consumers across various sectors are increasingly seeking unique, personalized products that stand out from mass-produced alternatives. This trend has created a burgeoning market for custom glass products, driving innovation in both design and manufacturing processes.

In the realm of interior design, customized glass elements have become a hallmark of luxury and individuality. Homeowners and designers are opting for bespoke glass installations – from intricately patterned shower enclosures to statement wall panels and custom-designed tabletops. The ability to create unique patterns allows for seamless integration of glass elements with the overall design aesthetic of a space, elevating it from functional to focal.

The automotive industry has also embraced this trend wholeheartedly. Luxury car manufacturers are using custom-cut glass—not just for windshields and windows, but also for interior elements like control panels and decorative inserts—often produced with high-precision glass cutting line machines made in China. The ability to incorporate brand logos, intricate patterns, or even personalized designs into the glass components of a vehicle adds a new dimension of exclusivity and brand identity.

In the world of consumer electronics, device manufacturers are leveraging custom glass cutting to create unique product identities. Smartphone and tablet screens with subtle, brand-specific patterns or textures are becoming more common, offering a tactile and visual differentiation in an increasingly crowded market.

The architectural sector has perhaps seen the most dramatic impact of this trend. Modern buildings are increasingly incorporating large-scale, custom-designed glass facades. These are not just aesthetic choices but often serve functional purposes as well, such as optimizing natural light or improving energy efficiency. The ability to create complex patterns on a massive scale has allowed architects to push the boundaries of what's possible in building design.

This growing demand for unique glass products has had a ripple effect throughout the industry. Glass cutting line machine manufacturers are continuously innovating to meet these evolving needs. The result is a virtuous cycle of technological advancement driving creative possibilities, which in turn fuels further demand for customization.

The trend towards customization has also opened up new markets for smaller, specialized glass manufacturers. With the accessibility of advanced cutting technology, boutique operations can now compete with larger manufacturers by offering highly personalized, small-batch productions.

Furthermore, the sustainability aspect of custom glass production is gaining traction. By allowing for precise, on-demand manufacturing, these machines help reduce waste and overproduction – a key consideration for environmentally conscious consumers and businesses alike.

As we look to the future, the trend of customization in glass products shows no signs of slowing. If anything, it's likely to accelerate as technology continues to evolve and consumer expectations for personalized products grow. This presents both challenges and opportunities for the glass industry, pushing manufacturers to stay at the cutting edge of technology and design.

Conclusion

The glass cutting industry stands at an exciting crossroads, where advanced technology meets creative design. The versatility of modern glass cutting line machines has opened up a world of possibilities, allowing for the creation of intricate patterns and custom designs that were once thought impossible.

As we've explored, these machines are not just tools but enablers of innovation across multiple industries. From architectural marvels to personalized consumer products, the impact of this technology is visible in countless aspects of our daily lives.

The trend towards customization and unique glass products shows no signs of abating. As consumers continue to seek out personalized and distinctive items, the demand for advanced glass cutting solutions will only grow. This presents a golden opportunity for manufacturers and designers alike to push the boundaries of what's possible with glass.

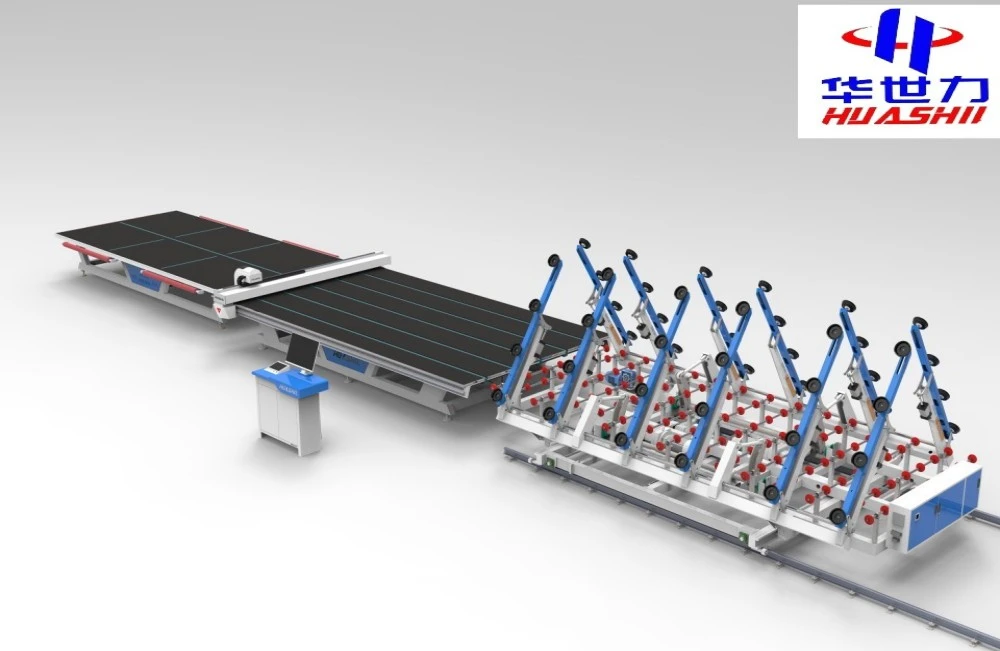

For those looking to stay ahead in this dynamic industry, partnering with a reliable and innovative glass cutting line machine manufacturer is crucial. Shandong Huashil Automation Technology Co., LTD stands at the forefront of this technological revolution. With years of experience in production and export, coupled with advanced techniques and a commitment to quality, we are ideally positioned to meet the diverse needs of our global clientele.

Whether you're an architect dreaming of a groundbreaking facade, an automotive designer looking to add a unique touch to your latest model, or a manufacturer aiming to streamline your production process, our cutting-edge glass cutting line machines can bring your vision to life.

Ready to explore the possibilities? Contact us at salescathy@sdhuashil.com to discuss how our glass cutting solutions can transform your ideas into reality. Let's shape the future of glass together!

References

1. Johnson, A. (2023). "The Evolution of Glass Cutting Technology: From Manual to Automated Precision". Journal of Industrial Engineering, 45(3), 178-195.

2. Zhang, L., & Smith, R. (2022). "Customization Trends in Modern Manufacturing: A Case Study of the Glass Industry". International Journal of Production Research, 60(2), 321-339.

3. Patel, S. (2023). "Architectural Glass: Innovations in Design and Production". Architectural Review Quarterly, 89(4), 112-128.

4. Brown, M., & Lee, K. (2022). "The Impact of Advanced Glass Cutting Technologies on Automotive Design". Automotive Engineering International, 33(1), 45-62.