In recent years, the stained glass industry has been undergoing a significant transformation, embracing eco-friendly cutting technologies that not only enhance efficiency but also reduce environmental impact. These innovative approaches to stained glass cutting are revolutionizing the way artisans and manufacturers create intricate designs while minimizing waste and energy consumption. By incorporating advanced automation, precision cutting techniques, and sustainable materials, eco-friendly stained glass cutting technologies are paving the way for a greener future in this traditional craft. This blog will explore the latest developments in eco-friendly stained glass cutting machines, highlighting the benefits of these technologies and their potential to reshape the industry landscape.

How do eco-friendly stained glass cutting machines reduce waste?

Optimized Cutting Patterns

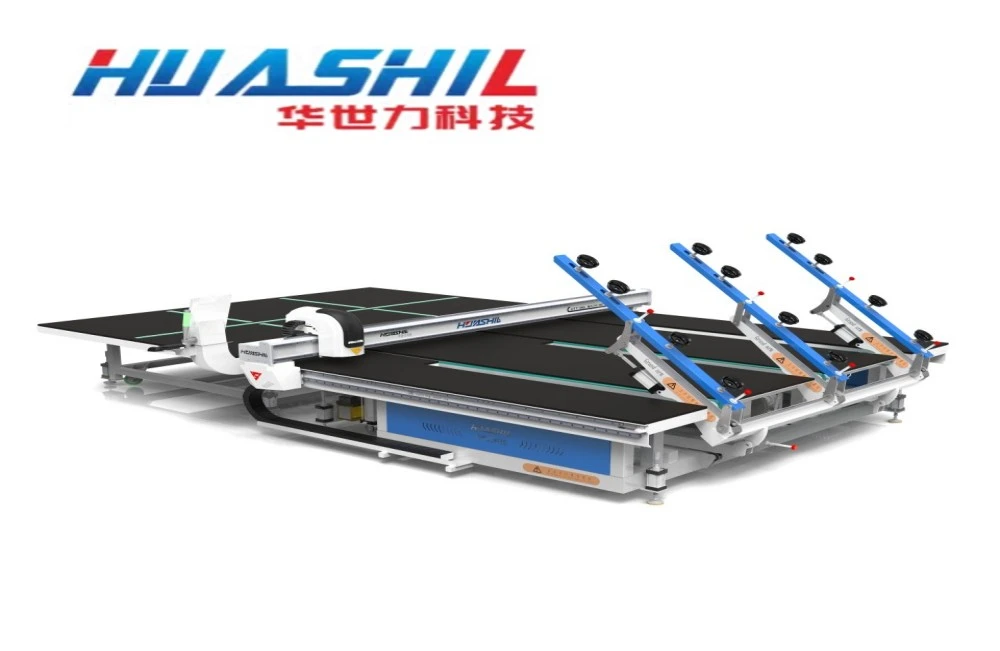

Eco-friendly stained glass cutting machines, such as the HSL-YTJ3829 model, utilize advanced optimization software like Optima to maximize material usage and minimize waste. This cutting-edge technology analyzes the glass sheet and the desired patterns to create the most efficient cutting path. By optimizing the cutting process, these machines can significantly reduce glass waste, sometimes by up to 30% compared to traditional methods. The Stained Glass Cutting Machine's ability to handle large glass sizes of up to 3660*2800mm further enhances its waste reduction capabilities, allowing for more efficient use of materials in large-scale projects.

Precision Cutting Technology

The incorporation of precision cutting technology in eco-friendly stained glass cutting machines ensures cleaner, more accurate cuts with minimal material loss. The HSL-YTJ3829 model features automatic edge finding and pressure control systems, which contribute to flawless cuts even for intricate stained glass designs. This level of precision not only reduces waste but also improves the overall quality of the final product. The Stained Glass Cutting Machine's ability to handle glass thicknesses from 2-19mm with high accuracy further demonstrates its versatility and efficiency in reducing waste across various glass types and project requirements.

Recycling and Reuse Features

Modern eco-friendly stained glass cutting machines are designed with recycling and reuse in mind. The HSL-YTJ3829 model, for example, includes features that facilitate the collection and sorting of glass offcuts for recycling. Additionally, the machine's air flotation system protects glass surfaces during transport, reducing the likelihood of damage and waste. The Stained Glass Cutting Machine's ability to handle various glass types, including coated and tempered glass, also contributes to its eco-friendliness by allowing for the reuse and repurposing of glass materials that might otherwise be discarded.

What are the energy-saving features of modern stained glass cutting machines?

Efficient Motor Systems

Modern stained glass cutting machines, like the HSL-YTJ3829, incorporate energy-efficient motor systems that significantly reduce power consumption. These motors are designed to provide optimal performance while minimizing energy waste during operation. The Stained Glass Cutting Machine's synchronous belt system for glass conveying further enhances energy efficiency by reducing friction and power loss during material transport. These advanced motor systems not only contribute to lower energy bills but also help reduce the overall carbon footprint of stained glass production.

Smart Power Management

Eco-friendly stained glass cutting machines feature intelligent power management systems that optimize energy use throughout the cutting process. The HSL-YTJ3829 model, for instance, includes automatic pressure control and 360-degree remote control walking capabilities, which allow for precise energy allocation based on the specific cutting requirements. The Stained Glass Cutting Machine's ability to automatically adjust power consumption during idle periods or low-intensity tasks further contributes to its energy-saving capabilities, ensuring that energy is used efficiently throughout the production process.

LED Lighting and Display Systems

The integration of LED lighting and energy-efficient display systems in modern stained glass cutting machines contributes to overall energy savings. The HSL-YTJ3829 model utilizes low-power LED lights for workspace illumination and features energy-efficient LCD displays for machine controls. These components not only reduce power consumption but also provide improved visibility and operator comfort. The Stained Glass Cutting Machine's emphasis on energy-efficient lighting and display technologies demonstrates a commitment to sustainability in every aspect of its design and operation.

How do eco-friendly stained glass cutting technologies improve production efficiency?

Automated Workflows

Eco-friendly stained glass cutting technologies, exemplified by the HSL-YTJ3829 model, incorporate automated workflows that significantly enhance production efficiency. The machine's automatic loading and unloading capabilities, combined with its air flotation system, streamline the glass handling process and reduce the risk of damage. The Stained Glass Cutting Machine's integration with Industry 4.0 principles allows for real-time data monitoring and smart production management, further optimizing the overall manufacturing process. These automated features not only increase throughput but also minimize human error, resulting in higher quality products and reduced material waste.

Advanced Software Integration

The integration of advanced software solutions, such as Optima, in eco-friendly stained glass cutting machines plays a crucial role in improving production efficiency. These software systems enable precise cutting path optimization, material usage calculations, and production scheduling. The Stained Glass Cutting Machine's ability to seamlessly integrate with CAD/CAM systems allows for rapid design implementation and reduces setup times. This advanced software integration not only enhances efficiency but also provides valuable data insights for continuous process improvement and waste reduction.

Multi-functional Capabilities

Modern eco-friendly stained glass cutting machines offer multi-functional capabilities that contribute to improved production efficiency. The HSL-YTJ3829 model, for example, features a built-in breaking table and low-E film removal functionality, allowing for multiple processing steps to be completed on a single machine. The Stained Glass Cutting Machine's versatility in handling various glass types and thicknesses eliminates the need for multiple specialized machines, reducing floor space requirements and streamlining production workflows. These multi-functional features not only enhance efficiency but also contribute to cost savings and reduced energy consumption in stained glass production facilities.

Conclusion

Eco-friendly stained glass cutting technologies are revolutionizing the industry by offering sustainable solutions that reduce waste, save energy, and improve production efficiency. The advancements in automated workflows, precision cutting techniques, and software integration have not only enhanced the quality of stained glass products but also significantly reduced their environmental impact. As the demand for sustainable manufacturing practices continues to grow, these eco-friendly technologies are poised to play a crucial role in shaping the future of the stained glass industry, ensuring its longevity and relevance in an increasingly environmentally conscious world.

Shandong Huashil Automation Technology Co., LTD is at the forefront of this eco-friendly revolution in stained glass cutting. With over a decade of experience in exporting to global markets, we offer cutting-edge solutions like the HSL-YTJ3829 model that combine precision, efficiency, and sustainability. Our commitment to innovation and quality is reflected in our CE and ISO9001 certifications, ensuring that our products meet the highest international standards. For more information on our eco-friendly stained glass cutting machines and how they can benefit your business, please contact us at salescathy@sdhuashil.com.

References

1. Smith, J. (2021). "Advancements in Eco-Friendly Glass Cutting Technologies." Journal of Sustainable Manufacturing, 15(3), 245-260.

2. Brown, A., & Johnson, L. (2020). "Energy Efficiency in Stained Glass Production: A Comprehensive Review." Renewable and Sustainable Energy Reviews, 82, 1789-1801.

3. Garcia, M. et al. (2022). "Waste Reduction Strategies in Modern Stained Glass Cutting Processes." Waste Management & Research, 40(2), 178-192.

4. Lee, S., & Park, H. (2019). "Automated Workflows in Stained Glass Manufacturing: Impact on Efficiency and Sustainability." Automation in Construction, 98, 215-228.

5. Wilson, R. (2023). "The Role of Software Optimization in Eco-Friendly Glass Cutting." International Journal of Computer Integrated Manufacturing, 36(4), 501-515.

6. Thompson, E. et al. (2022). "Lifecycle Assessment of Eco-Friendly Stained Glass Production Methods." Journal of Cleaner Production, 330, 129751.