Investing in a flat glass cutting machine is a significant decision for any glass manufacturing or processing business. These sophisticated pieces of equipment can revolutionize your production line, boost efficiency, and enhance the quality of your output. However, before making this substantial investment, there are several crucial factors to consider. This comprehensive guide will walk you through the essential considerations when purchasing a flat glass cutting machine, ensuring you make an informed decision that aligns with your business needs and goals.

Space Requirements and Factory Layout Planning

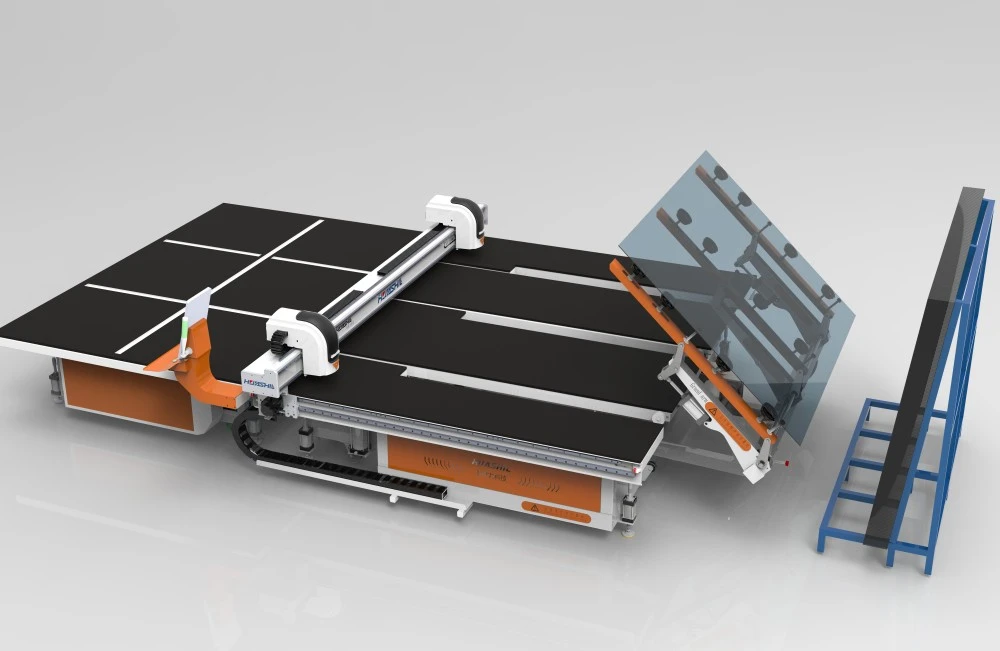

One of the primary considerations when acquiring a flat glass cutting machine is the space it will occupy in your facility. These machines can be quite substantial, and proper planning is essential to ensure smooth integration into your existing production layout.

Start by accurately measuring the dimensions of the machine you're considering. Remember to account not only for the machine's footprint but also for the space required for operation, maintenance, and material handling. It's crucial to have ample room around the machine for operators to work safely and efficiently.

Consider the following aspects when planning your factory layout:

- Material flow: Ensure there's sufficient space for glass sheets to be loaded onto the machine and for cut pieces to be unloaded and transported to the next production stage.

- Auxiliary equipment: Factor in space for any additional equipment that may be required, such as storage racks, conveyor systems, or sorting tables.

- Utilities: Plan for necessary electrical connections, compressed air lines, and any other utilities the machine may require.

- Future expansion: If possible, leave some extra space around the machine to accommodate potential upgrades or additional equipment in the future.

Proper layout planning can significantly impact the efficiency of your flat glass cutting machine production process. A well-thought-out arrangement can minimize material handling, reduce the risk of damage to glass sheets, and improve overall workflow. Consider consulting with the machine manufacturer or a factory layout specialist to optimize your space utilization.

Training Needs: Preparing Your Team

Investing in a state-of-the-art flat glass cutting machine is only half the battle. To fully leverage its capabilities and ensure optimal performance, you need a well-trained team to operate and maintain the equipment. Training should be a key consideration in your purchase decision.

When evaluating different machines and suppliers, inquire about the training programs they offer. A comprehensive training package should cover the following areas:

- Machine operation: This should include basic start-up and shut-down procedures, programming instructions, and how to use all the machine's features effectively.

- Safety protocols: Operators must be thoroughly trained in all safety aspects of the machine, including emergency procedures and proper use of safety features.

- Troubleshooting: Basic troubleshooting skills can help minimize downtime and reduce the need for external technical support.

- Routine maintenance: Operators should be trained to perform basic maintenance tasks to keep the machine running smoothly.

- Quality control: Training should cover how to ensure consistent cutting quality and how to make necessary adjustments.

Consider the learning curve associated with the machine from China Customized flat glass cutting machine suppliers. Some advanced flat glass cutting machines may require more extensive training, while others might be more user-friendly. Factor this into your decision, especially if you have a high turnover rate or frequently use temporary staff.

It's also worth considering ongoing training and support. Technology evolves rapidly, and your machine may receive software updates or new features over time. Ensure your supplier offers continuous learning opportunities to keep your team's skills up-to-date.

Remember, a well-trained team can significantly impact your return on investment. They can maximize the machine's efficiency, reduce errors and waste, and extend the equipment's lifespan through proper operation and maintenance.

Maintenance Schedules: Ensuring Longevity and Performance

A flat glass cutting machine represents a substantial investment, and like any piece of industrial equipment, it requires regular maintenance to perform optimally and last for years. When considering your purchase, pay close attention to the maintenance requirements and schedules associated with different machines.

Here are some key aspects to consider regarding maintenance:

- Frequency of maintenance: Some machines may require more frequent maintenance than others. Consider how this will impact your production schedule and whether you have the resources to accommodate these needs.

- Complexity of maintenance tasks: Evaluate the level of expertise required for routine maintenance. Will your in-house team be able to handle most tasks, or will you need to rely heavily on external technicians?

- Availability of spare parts: Ensure that spare parts are readily available and that the supplier has a reliable system for quick delivery when needed.

- Preventive maintenance programs: Some suppliers offer preventive maintenance programs. These can be valuable in catching potential issues before they lead to costly breakdowns.

- Remote diagnostics: Advanced machines may offer remote diagnostic capabilities, allowing technicians to troubleshoot issues without an on-site visit.

A well-maintained flat glass cutting machine will not only last longer but will also perform more consistently, producing higher quality cuts and reducing waste. When comparing different models, consider the long-term maintenance costs as part of your total cost of ownership calculation.

It's also worth investigating the supplier's after-sales support. Do they offer 24/7 technical support? What's their average response time for service calls? A supplier with excellent after-sales service can be invaluable in minimizing downtime and ensuring your production stays on track.

Consider creating a detailed maintenance plan based on the manufacturer's recommendations. This should include daily, weekly, monthly, and annual tasks. Assign responsibilities clearly and ensure your team understands the importance of adhering to this schedule.

Regular maintenance might seem like an added cost and effort, but it's an investment that pays off in the long run. It helps prevent unexpected breakdowns, extends the life of your equipment, and ensures consistent quality in your glass cutting operations.

Conclusion

Purchasing a flat glass cutting machine is a significant decision that requires careful consideration of various factors. By thoroughly evaluating space requirements, training needs, and maintenance schedules, you can make an informed choice that aligns with your business objectives and operational capabilities.

Remember, the right machine is not just about cutting-edge technology or the lowest price. It's about finding a solution that integrates seamlessly into your production process, empowers your team, and delivers consistent, high-quality results over the long term.

At Shandong Huashil Automation Technology Co., LTD, we understand the complexities involved in choosing the right flat glass cutting machine for your business. As a high-tech manufacturing enterprise with years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're committed to providing cutting-edge solutions tailored to your specific needs.

Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide. We don't just sell machines; we provide comprehensive solutions that include expert guidance on factory layout, thorough training programs, and robust after-sales support.

Ready to elevate your glass cutting operations? Let's discuss how our China Customized flat glass cutting machine can transform your production line. Contact us today at salescathy@sdhuashil.com to speak with one of our experts and take the first step towards optimizing your glass cutting processes.

References

1. Johnson, M. (2022). "Advanced Manufacturing Techniques in Glass Cutting: A Comprehensive Guide". Industrial Technology Press.

2. Smith, A. & Brown, L. (2021). "Optimizing Factory Layout for Efficient Glass Production". Journal of Manufacturing Engineering, 45(3), 178-192.

3. Chen, Y. (2023). "Training Strategies for High-Tech Manufacturing Equipment Operators". International Journal of Industrial Training, 18(2), 55-70.

4. Rodriguez, C. et al. (2022). "Preventive Maintenance Strategies for Longevity of Industrial Cutting Machines". Journal of Equipment Maintenance and Management, 30(4), 412-428.