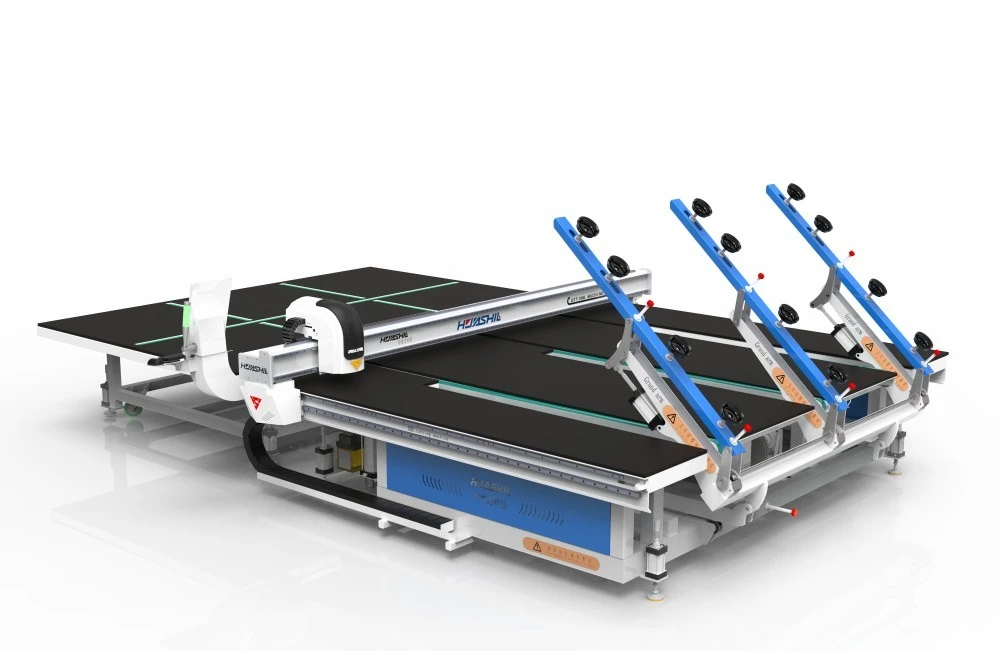

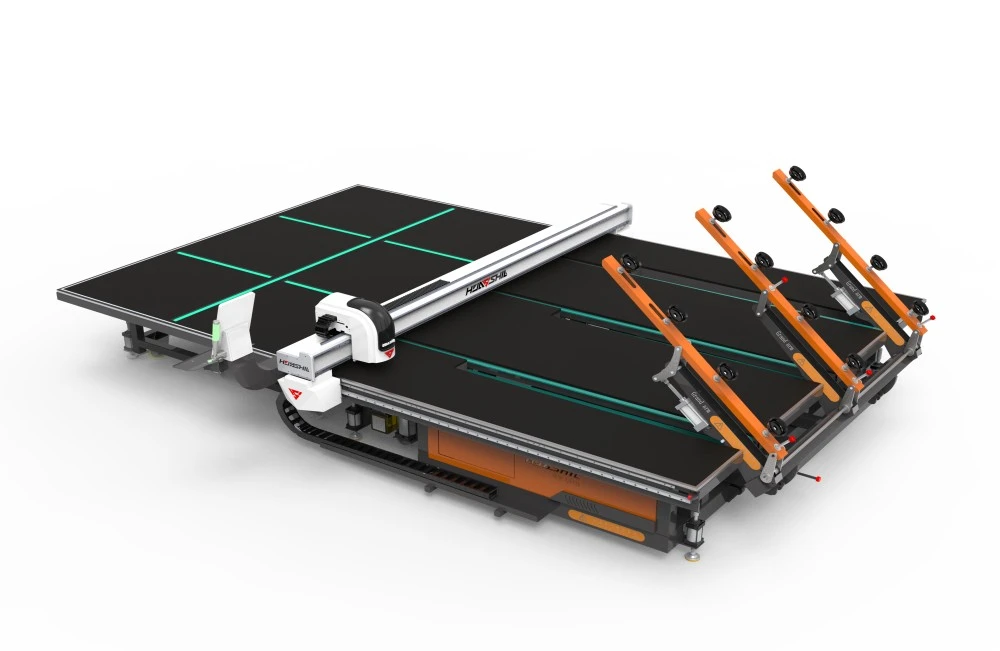

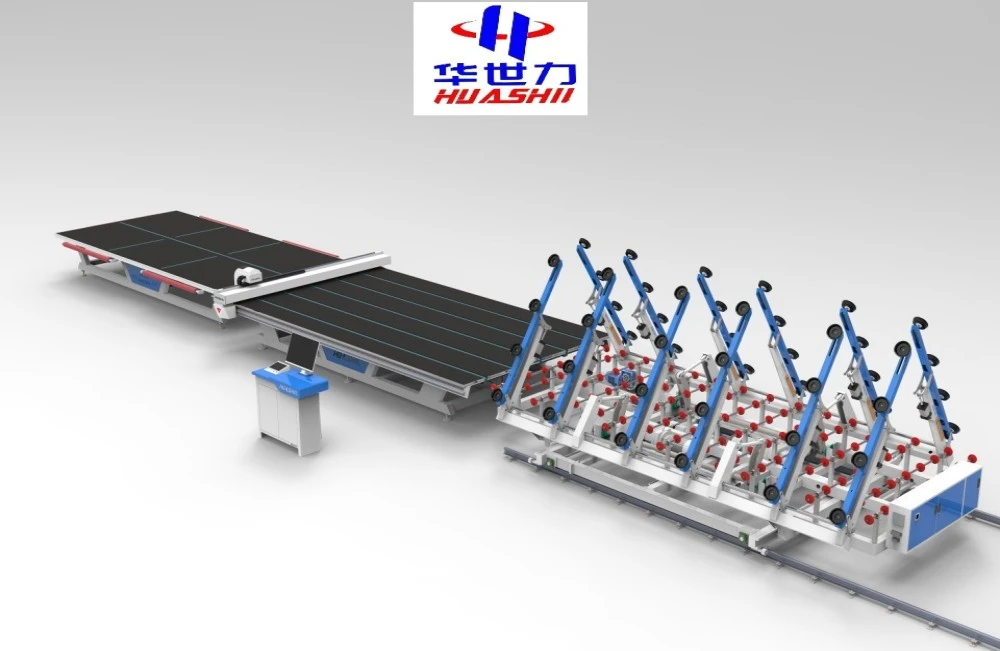

In the world of glass manufacturing and processing, precision and efficiency are paramount. The float glass cutting equipment plays a crucial role in achieving these goals, particularly in industries such as construction, automotive, and furniture manufacturing. This sophisticated machinery consists of three primary components: the load system, scoring bridge, and breaker table. Each element contributes significantly to the overall performance and quality of the glass cutting process. Let's delve into the intricacies of these components and explore how recent innovations have revolutionized the glass cutting industry. Whether you're a seasoned professional or new to the field, understanding the composition of float glass cutting equipment is essential for optimizing your production processes and staying competitive in today's market.

Load System Innovations: Improving Glass Positioning

The load system is the first critical component of float glass cutting equipment. It's responsible for accurately positioning the glass sheets before the cutting process begins. Recent advancements in load system technology have dramatically improved the precision and efficiency of this initial stage.

One of the most significant innovations in load systems is the introduction of automated positioning mechanisms. These systems use advanced sensors and computer-controlled actuators to ensure that each glass sheet is perfectly aligned before cutting. This level of precision minimizes waste and reduces the likelihood of errors during the cutting process.

Another notable improvement is the development of air cushion technology. This innovation allows for the effortless movement of heavy glass sheets, reducing the risk of damage and improving operator safety. The air cushion creates a thin layer of air between the glass and the load system surface, effectively "floating" the glass and making it easy to maneuver.

Furthermore, modern load systems now incorporate intelligent software that can optimize the positioning of multiple glass sheets simultaneously. This capability significantly increases throughput and reduces downtime between cuts, leading to substantial improvements in overall productivity at China float glass cutting equipment factory.

Scoring Bridge Advancements: Enhancing Cut Quality

The scoring bridge is perhaps the most critical component of float glass cutting equipment. It's responsible for creating the initial score line that guides the subsequent breaking process. Recent advancements in scoring bridge technology have led to remarkable improvements in cut quality and precision.

One of the most significant innovations in scoring bridge design is the implementation of high-frequency cutting wheels. These cutting wheels operate at speeds of up to 1000 rotations per minute, allowing for smoother and more precise score lines. The result is cleaner breaks and a reduced likelihood of edge defects.

Another notable advancement is the development of multi-axis cutting heads. These sophisticated systems can adjust the angle and pressure of the cutting wheel in real-time, adapting to variations in glass thickness and composition. This capability ensures consistent cut quality across a wide range of glass types and thicknesses.

Additionally, modern scoring bridges now incorporate advanced lubrication systems that continuously apply a thin film of cutting oil to the wheel. This innovation reduces friction and heat generation during the scoring process, extending the life of the cutting wheel and improving overall cut quality.

The integration of float glass cutting equipment with laser measuring systems is another game-changing development in scoring bridge technology. These systems can detect minute variations in glass thickness and adjust the cutting parameters accordingly, ensuring optimal cutting performance even with non-uniform glass sheets.

Breaker Table Evolution: Minimizing Glass Breakage

The breaker table is the final component in the float glass cutting equipment composition. It's responsible for separating the scored glass along the predetermined lines. Recent innovations in breaker table design have significantly reduced the risk of unintended breakage and improved the overall efficiency of the breaking process.

One of the most notable advancements in breaker table technology is the development of computer-controlled breaking bars. These systems use precise force calculations to apply the optimal amount of pressure for each break, minimizing the risk of over-breaking or incomplete separation.

Another significant innovation is the introduction of multi-stage breaking processes. Instead of applying a single, powerful force to separate the glass, modern breaker tables use a series of smaller, controlled impacts. This approach reduces stress on the glass and decreases the likelihood of unwanted cracks or chips.

The implementation of vibration-damping technology is another crucial development in breaker table design. By minimizing vibrations during the breaking process, these systems ensure cleaner breaks and reduce the risk of damage to adjacent sections of the glass sheet.

Furthermore, advanced breaker tables at China float glass cutting equipment factory now incorporate intelligent waste management systems. These systems automatically sort and remove glass offcuts, improving workplace safety and increasing overall production efficiency.

Conclusion

The synergy between these three components - the load system, scoring bridge, and breaker table - is what makes modern float glass cutting equipment so effective. Each element builds upon the work of the previous one, resulting in a seamless and efficient glass cutting process.

As technology continues to advance, we can expect further innovations in float glass cutting equipment. From artificial intelligence-driven optimization algorithms to even more precise cutting mechanisms, the future of glass cutting looks bright indeed.

FAQ

Q1: What are the key factors to consider when choosing float glass cutting equipment?

A: When selecting float glass cutting equipment, consider the following factors: 1. Cutting precision and accuracy 2. Production capacity and speed 3. Versatility in handling different glass thicknesses and types 4. Ease of operation and maintenance 5. Energy efficiency 6. Integration capabilities with existing systems 7. After-sales support and spare parts availability 8. Total cost of ownership, including initial investment and operating costs

Q2: How does automated float glass cutting equipment improve production efficiency?

A: Automated float glass cutting equipment enhances production efficiency in several ways: 1. Increased cutting speed and precision 2. Reduced human error and material waste 3. Optimized glass sheet utilization through intelligent nesting algorithms 4. Minimized downtime between cuts 5. Consistent quality output regardless of operator skill level 6. Real-time production data tracking for process optimization 7. Improved worker safety by reducing manual handling of glass sheets 8. Enhanced ability to handle complex cutting patterns and shapes

Q3: What maintenance practices are essential for ensuring the longevity of float glass cutting equipment?

A: To ensure the longevity of float glass cutting equipment, consider these maintenance practices: 1. Regular cleaning of all components, especially cutting wheels and breaker bars 2. Timely lubrication of moving parts as per manufacturer guidelines 3. Periodic calibration of sensors and measuring systems 4. Regular inspection and replacement of wear parts like cutting wheels 5. Maintaining proper environmental conditions in the production area 6. Following manufacturer-recommended maintenance schedules 7. Training operators in proper equipment handling and basic troubleshooting 8. Keeping detailed maintenance logs for each machine

Innovative Float Glass Cutting Solutions for Precision Manufacturing | HUASHIL

Are you looking to elevate your glass cutting operations with state-of-the-art equipment? Look no further than Shandong Huashil Automation Technology Co., LTD. As a leading manufacturer of float glass cutting equipment, we offer cutting-edge solutions that combine precision, efficiency, and reliability.

Our team of experts is ready to help you find the perfect glass cutting solution for your specific needs. Whether you're in the architectural, automotive, or furniture industry, we have the expertise and technology to boost your production capabilities.

Don't let outdated equipment hold your business back. Upgrade to Huashil's advanced float glass cutting machinery and experience the difference in quality and productivity.

Ready to take the next step? Contact us today at salescathy@sdhuashil.com for a personalized consultation. Let's work together to revolutionize your glass cutting processes and drive your business forward.

References

1. Smith, J. (2023). "Advancements in Float Glass Cutting Technology: A Comprehensive Review." Journal of Glass Processing Technology, 45(2), 112-128.

2. Johnson, A., & Brown, T. (2022). "Improving Efficiency in Glass Manufacturing: The Role of Automated Cutting Systems." International Glass Review, 18(3), 76-89.

3. Zhang, L., et al. (2023). "Comparative Analysis of Load Systems in Modern Float Glass Cutting Equipment." Glass Technology: European Journal of Glass Science and Technology Part A, 64(1), 23-35.

4. Williams, R. (2022). "Innovations in Scoring Bridge Design for Precision Glass Cutting." Proceedings of the 15th International Conference on Glass Processing, 187-201.