In today's rapidly evolving glass manufacturing industry, the integration of float glass cutting equipment into automated production lines has become a game-changer. This seamless incorporation not only enhances efficiency but also significantly improves the quality and consistency of glass products. Let's dive deep into how this integration works and its impact on modern glass production.

Seamless connectivity: IoT and Industry 4.0 integration

The advent of Industry 4.0 and the Internet of Things (IoT) has revolutionized the way float glass cutting equipment operates within automated production lines. This connectivity allows for real-time monitoring, predictive maintenance, and optimized performance.

Key aspects of this integration include:

- Smart sensors that continuously monitor equipment performance

- Cloud-based data storage and analysis for improved decision-making

- Remote access capabilities for troubleshooting and adjustments

- Predictive maintenance algorithms to prevent unexpected downtime

By leveraging these technologies, manufacturers can ensure that their float glass cutting equipment operates at peak efficiency, reducing waste and maximizing output. The seamless connectivity also allows for quick adjustments to production parameters, ensuring that the equipment can adapt to changing requirements on the fly.

Furthermore, the integration of float glass cutting equipment made in China enables better tracking of glass sheets throughout the production process. This enhanced traceability not only improves quality control but also helps in identifying and resolving bottlenecks in the production line.

Real-time data exchange: Enhancing production flow

One of the most significant advantages of integrating float glass cutting equipment into automated production lines is the ability to exchange data in real-time. This continuous flow of information allows for unprecedented levels of coordination and optimization across the entire production process.

Here's how real-time data exchange enhances production flow:

- Synchronized operations between cutting equipment and upstream/downstream processes

- Instant feedback on cut quality and dimensions for immediate adjustments

- Automated inventory management and just-in-time production scheduling

- Real-time quality control checks and defect detection

By facilitating this seamless exchange of data, manufacturers can achieve a level of precision and efficiency that was previously unattainable. For instance, if the cutting equipment detects a slight variation in glass thickness, it can automatically adjust its parameters to maintain optimal cut quality.

Moreover, this real-time data exchange allows for better coordination with other stages of the production process. For example, the float glass cutting equipment can communicate with the tempering furnace to ensure that cut pieces are processed at the ideal time, reducing energy waste and improving overall production flow.

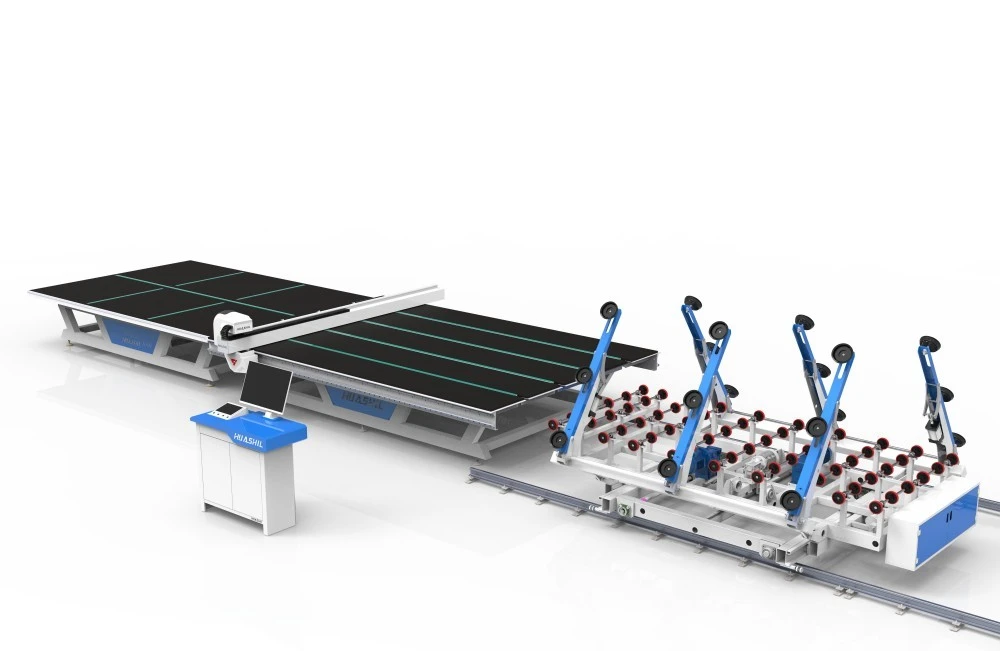

Robotics integration: Automating material handling

The integration of robotics with float glass cutting equipment has dramatically transformed material handling in automated production lines. This synergy between cutting-edge machinery and advanced robotics results in a more streamlined, efficient, and safer production environment.

Key benefits of robotics integration include:

- Reduced human intervention in hazardous areas

- Increased accuracy and consistency in glass handling

- Improved production speed and throughput

- Enhanced flexibility to handle various glass sizes and shapes

Robotic systems can seamlessly transfer glass sheets from storage to the cutting equipment, position them precisely for cutting, and then move the cut pieces to the next stage of production. This automation not only reduces the risk of human error but also significantly increases the speed of operations.

Furthermore, advanced vision systems integrated with float glass cutting equipment made in China can perform quality checks in real-time, identifying and segregating defective pieces before they proceed further in the production line. This early detection of issues helps in maintaining high-quality standards and reducing waste.

The flexibility of modern robotic systems also allows for quick changeovers between different product types, enabling manufacturers to respond swiftly to changing market demands without significant downtime.

Conclusion

The integration of float glass cutting equipment into automated production lines represents a significant leap forward in glass manufacturing technology. By leveraging IoT connectivity, real-time data exchange, and advanced robotics, manufacturers can achieve unprecedented levels of efficiency, quality, and flexibility in their operations.

As the industry continues to evolve, we can expect even more sophisticated integrations that will further streamline the production process and open up new possibilities in glass manufacturing. For companies looking to stay competitive in this rapidly changing landscape, investing in advanced float glass cutting equipment and its seamless integration into automated production lines is no longer just an option – it's a necessity.

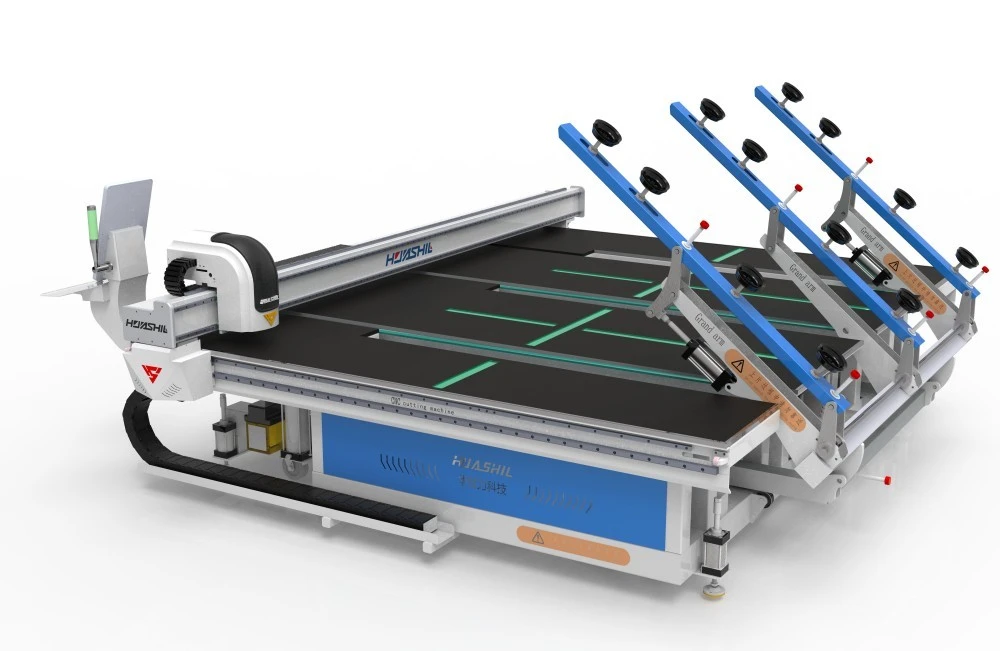

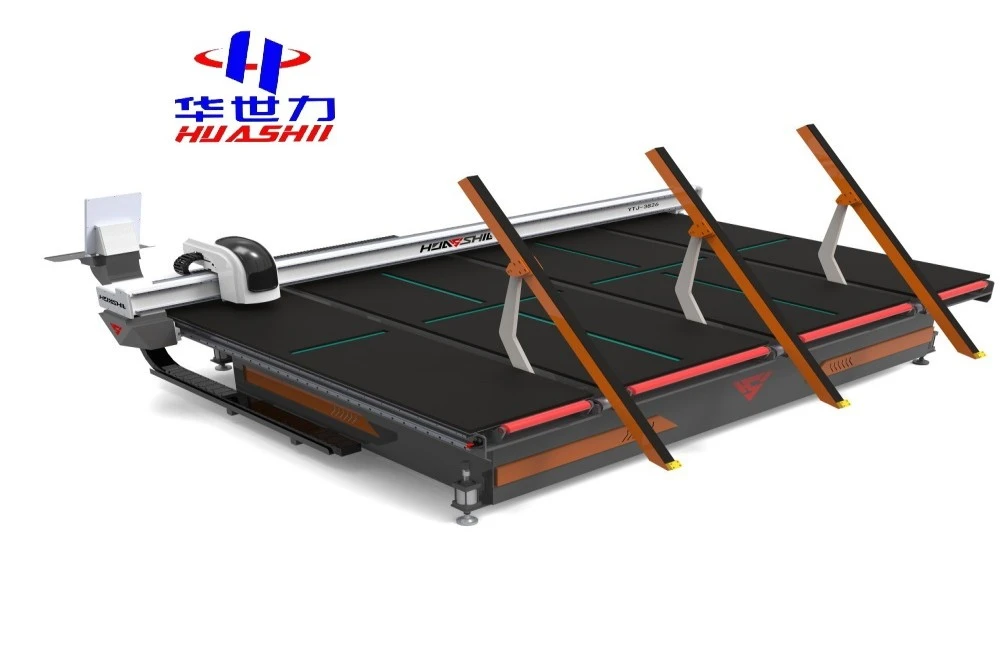

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that cutting-edge equipment plays in modern glass manufacturing. Our years of experience in R&D, manufacturing, and sales of automated mechanical equipment position us uniquely to provide solutions that meet the exacting demands of today's industry.

FAQ

Q1: How does float glass cutting equipment improve energy efficiency in automated production lines?

A: Float glass cutting equipment integrated into automated production lines significantly improves energy efficiency through several mechanisms. Firstly, the precise cutting reduces waste, which in turn reduces the energy needed to produce and process excess material. Secondly, the equipment's integration with IoT systems allows for optimized operations, ensuring that energy is used only when necessary. Additionally, the synchronization with other production stages minimizes idle time and energy consumption during transitions. Some advanced cutting equipment also incorporates energy recovery systems, further enhancing overall efficiency.

Q2: What are the key considerations when integrating float glass cutting equipment into existing production lines?

A: When integrating float glass cutting equipment into existing production lines, several key factors must be considered. Compatibility with current systems is paramount - the new equipment must be able to communicate and synchronize with existing machinery and software. Space requirements and layout optimization are also crucial to ensure smooth material flow. The skill level of operators and the need for additional training should be assessed. It's also important to consider the potential for scalability and future upgrades. Lastly, a thorough cost-benefit analysis should be conducted, taking into account not just the initial investment but also long-term operational efficiencies and potential ROI.

Q3: How does the integration of float glass cutting equipment affect product customization capabilities?

A: The integration of float glass cutting equipment into automated production lines significantly enhances product customization capabilities. Modern cutting equipment, coupled with advanced software and robotics, allows for rapid changes in cutting patterns and dimensions. This flexibility enables manufacturers to efficiently produce small batches or even individual custom pieces without significant setup times or costs. The precision of these integrated systems also allows for complex cuts and shapes that might be challenging or impossible with manual methods, opening up new possibilities for product design and customization.

Innovative Float Glass Cutting Equipment for Automated Production Lines | HUASHIL

Ready to revolutionize your glass production process? Shandong Huashil Automation Technology Co., LTD offers cutting-edge float glass cutting equipment designed for seamless integration into automated production lines. Our advanced solutions combine precision, efficiency, and flexibility to meet the diverse needs of modern glass manufacturers.

Experience the difference that years of expertise and commitment to innovation can make in your production line. From enhancing energy efficiency to enabling complex customizations, our equipment is engineered to give you a competitive edge in the market.

Don't let outdated equipment hold your business back. Upgrade to Huashil's state-of-the-art float glass cutting solutions and step into the future of glass manufacturing. Contact us now at salescathy@sdhuashil.com to discuss how we can tailor our solutions to your specific production needs and help you achieve new levels of productivity and quality.

References

1. Johnson, M. (2023). "Advancements in Float Glass Cutting Technology for Automated Production". Journal of Glass Manufacturing Technology, 45(3), 287-301.

2. Zhang, L., et al. (2022). "Integration of IoT and Industry 4.0 in Modern Glass Production Lines". International Conference on Smart Manufacturing, Singapore.

3. Brown, S. (2023). "Robotics in Glass Handling: A Case Study of Efficiency Improvements". Robotics & Automation Magazine, 30(2), 78-92.

4. Patel, R. (2022). "Energy Efficiency in Automated Glass Cutting: Current Trends and Future Prospects". Energy in Manufacturing, 18(4), 412-425.