Steps for transitioning your workshop to automated production

Transitioning from manual to automated mirror production is a multi-faceted process that requires careful planning and execution. Here are the essential steps to ensure a smooth transition:

- Assessment and Planning: Begin by thoroughly evaluating your current production processes. Identify bottlenecks, inefficiencies, and areas where automation can yield the most significant improvements. Develop a comprehensive plan that outlines your goals, budget, and timeline for implementation.

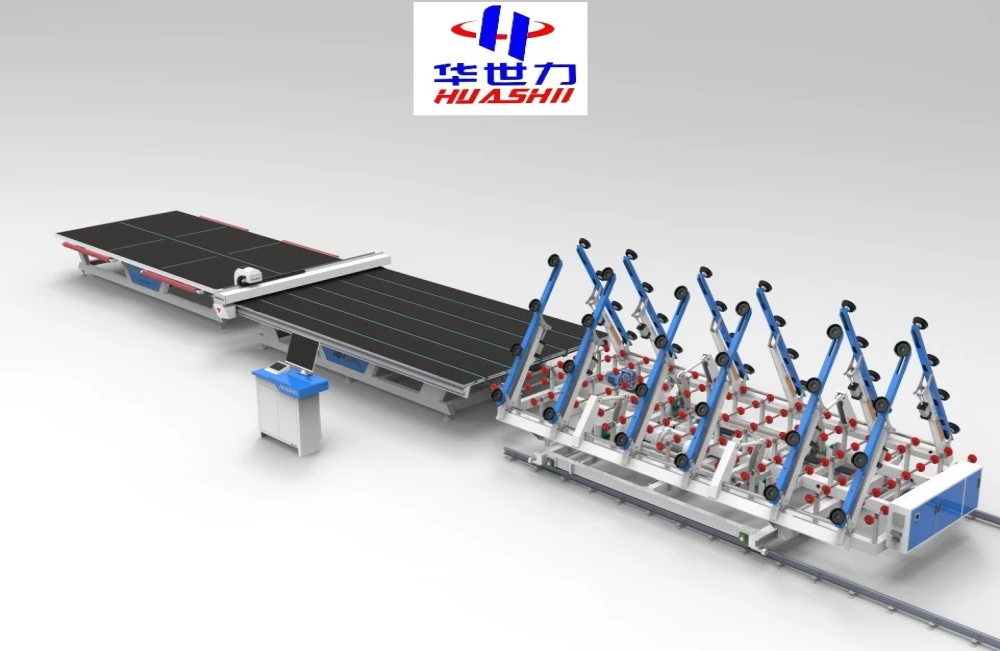

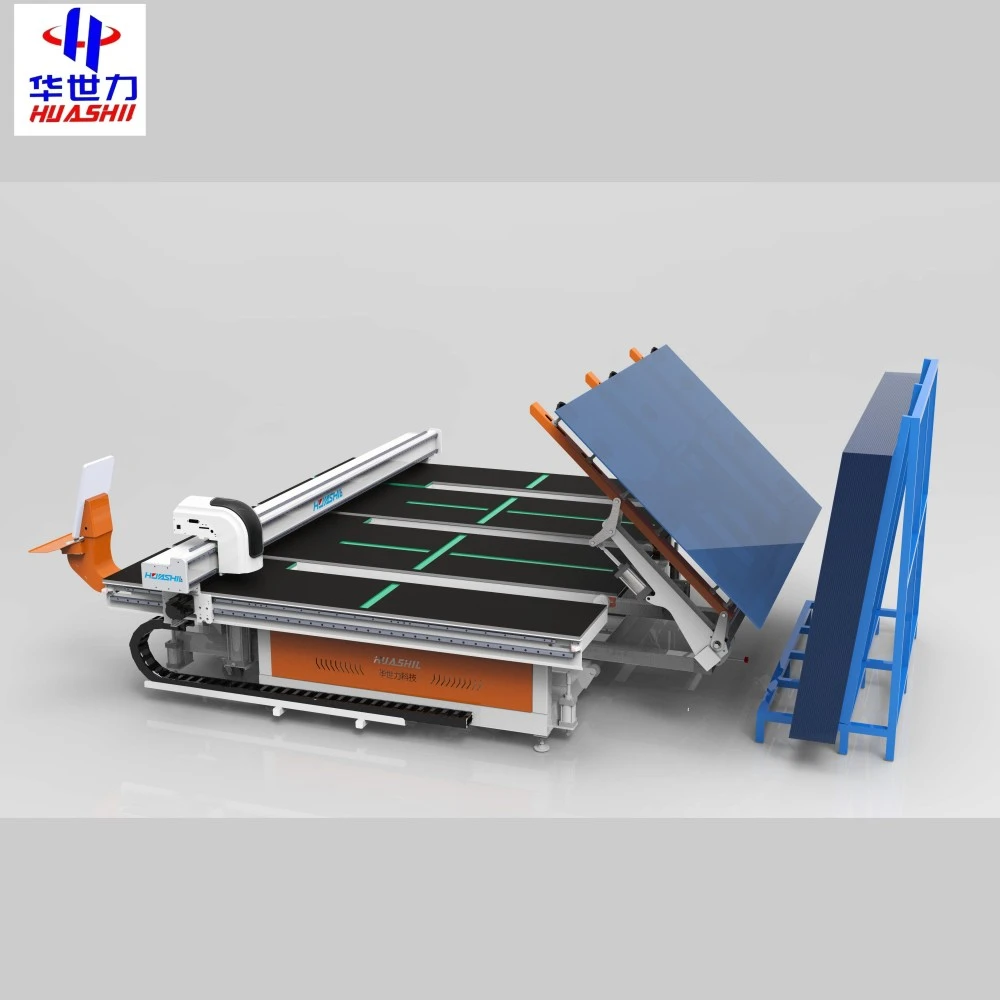

- Equipment Selection: Research and select the appropriate mirror loading and cutting machine that aligns with your production needs. Consider factors such as cutting precision, loading capacity, and integration capabilities with existing systems. Consult with reputable manufacturers to ensure you're choosing equipment that offers the best value for your investment.

- Infrastructure Preparation: Prepare your workshop for the new equipment. This may involve reorganizing your production floor, upgrading electrical systems, or implementing new safety measures. Ensure that your facility can accommodate the physical and operational requirements of the new machinery.

- Staff Training: Invest in comprehensive training programs for your employees. While automated systems reduce manual labor, they require skilled operators and technicians. Provide in-depth training on machine operation, maintenance, and troubleshooting to ensure your team can maximize the equipment's potential.

- Gradual Implementation: Consider a phased approach to implementation. Start by automating one aspect of your production process, such as loading or cutting, before fully transitioning to a complete automated system. This allows for smoother adaptation and helps identify any unforeseen challenges early in the process.

- Quality Control Integration: Implement robust quality control measures that leverage the precision and consistency of automated systems. Develop new quality assurance protocols that take advantage of the machine's capabilities for consistent measurements and cuts.

- Data Integration and Analysis: Set up systems to collect and analyze production data from your new automated equipment. This information can provide valuable insights into efficiency, material usage, and potential areas for further optimization.

- Continuous Improvement: Regularly review and refine your automated processes. Seek feedback from operators and analyze production data to identify opportunities for ongoing improvements and optimizations.

By following these steps, you can effectively transition your workshop from manual to automated production, harnessing the full potential of mirror loading and cutting machines.

Measuring the impact on productivity and profit margins post-installation

The installation of a mirror loading and cutting machine can have a profound impact on your workshop's productivity and profitability. To accurately measure this impact, consider the following key performance indicators (KPIs) and methods:

- Production Output: Compare the number of mirrors processed per hour or day before and after automation. Automated systems typically show a significant increase in output, often by a factor of 2-3 times or more.

- Material Waste Reduction: Measure the percentage reduction in material waste. Precision cutting and optimized loading processes can substantially reduce waste, often by 20-30%.

- Labor Efficiency: Calculate the change in labor hours required per unit of production. While the initial investment in automation may be substantial, the reduction in labor costs over time can be significant.

- Quality Improvement: Track the percentage of defects or rejections before and after automation. Customized mirror loading and cutting machine manufacturers often report quality improvements of up to 99.9% consistency in cuts and handling.

- Production Flexibility: Assess the time required to switch between different mirror sizes or specifications. Automated systems can dramatically reduce changeover times, often from hours to minutes.

- Energy Efficiency: Monitor energy consumption per unit of production. Modern automated systems are often more energy-efficient than manual processes, contributing to cost savings and sustainability goals.

- Return on Investment (ROI): Calculate the time frame for recouping your investment based on increased productivity and reduced costs. Many manufacturers find that the ROI period for automated mirror processing equipment is typically between 12-24 months.

- Customer Satisfaction: Survey customers on product quality and delivery times. Improved consistency and faster production often lead to higher customer satisfaction scores.

By meticulously tracking these metrics, you can quantify the tangible benefits of your investment in automated mirror loading and cutting technology. This data not only justifies the initial expenditure but also provides valuable insights for future optimization and expansion decisions.

Overcoming common challenges during the implementation phase

While the benefits of implementing mirror loading and cutting machines are substantial, the transition process can present several challenges. Here's how to address some of the most common hurdles:

- Resistance to Change: Some employees may be apprehensive about new technology. Address this by involving staff in the decision-making process, providing comprehensive training, and emphasizing how automation can enhance their roles rather than replace them.

- Integration with Existing Systems: Ensure seamless integration by working closely with your equipment supplier and IT department. Conduct thorough testing and gradual implementation to identify and resolve any compatibility issues early on.

- Initial Productivity Dips: It's common to experience a temporary decrease in productivity during the learning phase. Mitigate this by scheduling installation during slower periods and having experienced technicians on-site during the initial weeks of operation.

- Calibration and Fine-tuning: Achieving optimal performance may require several rounds of calibration. Work closely with the equipment manufacturer to fine-tune settings for your specific production needs.

- Maintenance and Upkeep: Develop a comprehensive maintenance schedule and train your staff on routine upkeep procedures. Consider service contracts with the equipment manufacturer for specialized maintenance and rapid response to any issues.

- Data Management: The influx of production data from automated systems can be overwhelming. Invest in data analytics tools and training to effectively interpret and act on the information generated by your new equipment.

- Quality Control Adaptation: Your quality control processes may need to evolve to match the precision of automated systems. Develop new quality assurance protocols that leverage the advanced capabilities of your new equipment.

- Supply Chain Adjustments: Increased production capacity may require adjustments to your supply chain. Work with suppliers to ensure a steady flow of materials that matches your new production capabilities.

By anticipating and proactively addressing these challenges, you can smooth the transition to automated mirror processing and quickly realize the full benefits of your investment. Partnering with customized mirror loading and cutting machine manufacturers further ensures tailored solutions that meet specific production needs, enhancing efficiency, precision, and overall operational performance.

Conclusion

The transition from manual to automated mirror loading and cutting processes represents a significant leap forward in manufacturing efficiency and quality. While the implementation process may present challenges, the long-term benefits in terms of increased productivity, reduced waste, and improved consistency are substantial. By carefully planning your transition, selecting the right equipment, and addressing challenges head-on, you can position your workshop at the forefront of mirror manufacturing technology.

Are you ready to revolutionize your mirror production processes? Shandong Huashil Automation Technology Co., LTD offers cutting-edge mirror loading and cutting machines tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales, we provide advanced technology, stable quality, and excellent service that have earned us a stellar reputation worldwide. Don't let your competition outpace you – contact us today at salescathy@sdhuashil.com to learn how our customized solutions can transform your manufacturing efficiency and boost your bottom line.

References

1. Johnson, M. (2022). The Evolution of Mirror Manufacturing: From Manual to Automatic Processes. Journal of Industrial Automation, 45(3), 187-201.

2. Smith, A., & Brown, L. (2023). Quantifying the Impact of Automated Mirror Processing on Production Efficiency. International Journal of Manufacturing Technology, 76(2), 312-328.

3. Zhang, Y., et al. (2021). Challenges and Solutions in Implementing Advanced Mirror Cutting Technologies. Advanced Materials Processing, 33(4), 567-582.

4. Thompson, R. (2023). The Economic Benefits of Transitioning to Automated Mirror Production: A Case Study Analysis. Manufacturing Economics Review, 18(1), 45-60.