In the ever-evolving world of glass manufacturing and processing, the debate between automated and manual methods continues to be a hot topic. This comprehensive analysis delves into the intricacies of mirror loading and cutting machines versus traditional manual cutting techniques, offering valuable insights for industry professionals and decision-makers alike.

Accuracy comparison: machine precision vs. human error

When it comes to precision in mirror cutting, the disparity between automated machines and manual methods is stark. Customized mirror loading and cutting machine manufacturers have revolutionized the industry by introducing equipment capable of achieving unprecedented levels of accuracy.

Automated cutting systems typically boast cutting tolerances within 0.1 millimeters, a level of precision that is virtually impossible to achieve consistently through manual methods. This razor-sharp accuracy is crucial in industries such as automotive manufacturing, aerospace, and high-end architectural design, where even the slightest deviation can lead to significant issues down the line.

Human operators, no matter how skilled, are susceptible to fatigue, distractions, and natural variations in performance. These factors inevitably lead to inconsistencies in cut quality and dimensions. Manual cutting also relies heavily on individual judgment and experience, which can vary from one operator to another, resulting in potential discrepancies between different production batches.

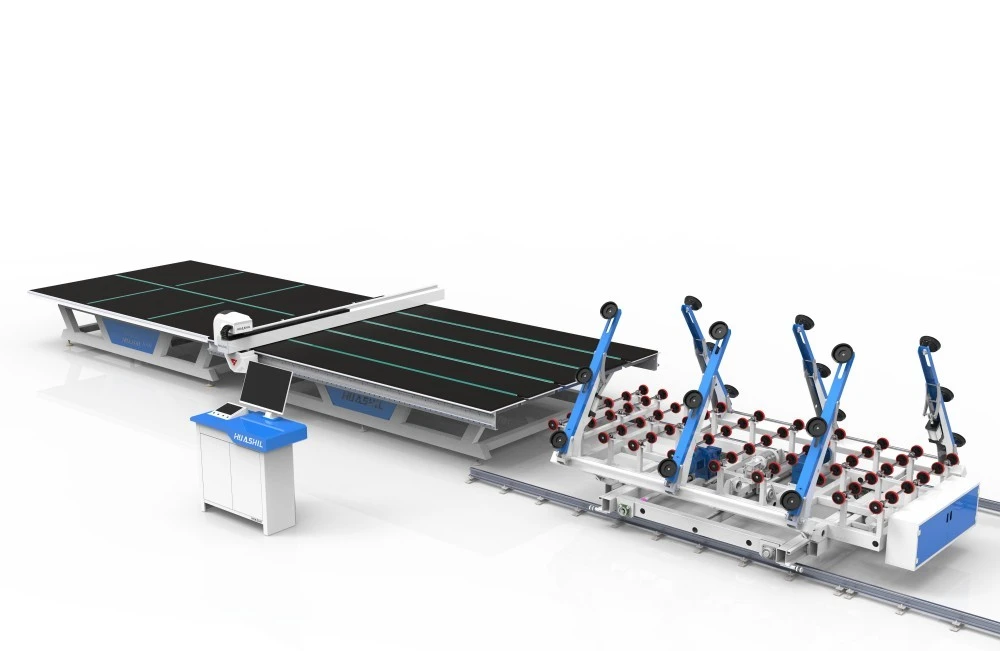

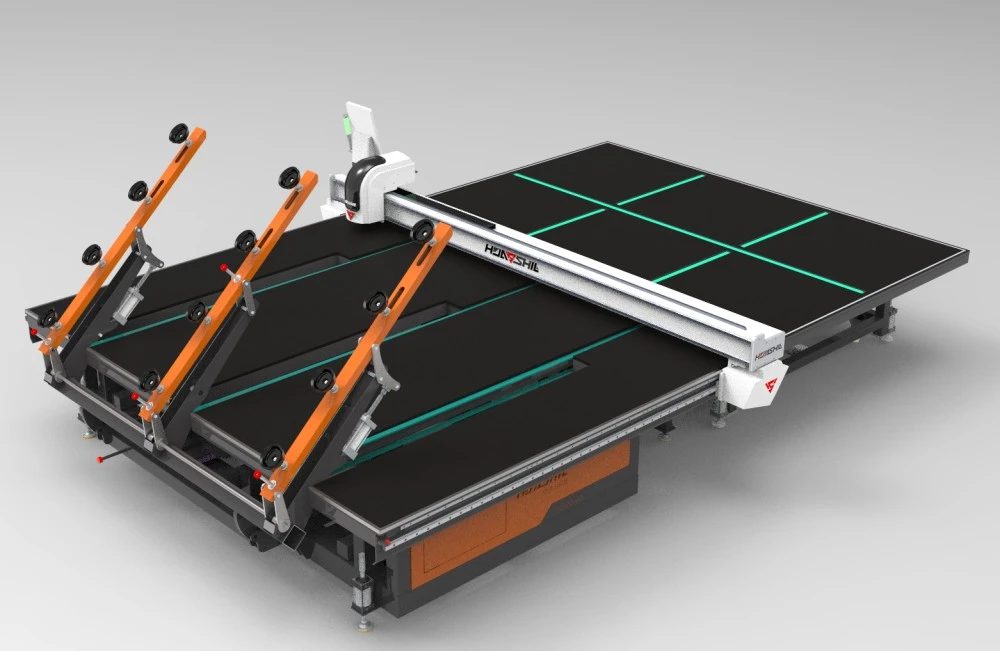

In contrast, mirror loading and cutting machines maintain unwavering precision throughout extended production runs. They utilize advanced computer vision systems and laser-guided cutting technologies that ensure each cut is executed with exacting standards. This level of consistency not only enhances product quality but also significantly reduces material waste – a crucial factor in improving overall operational efficiency.

Moreover, automated systems can rapidly adjust to different mirror specifications without the need for extensive recalibration. This flexibility is particularly valuable in environments where diverse product lines or frequent design changes are the norm. The ability to switch between different cutting patterns or mirror thicknesses with minimal downtime represents a significant advantage over manual methods, which often require more time-consuming setup processes.

Which method offers better handling for large, thick mirrors?

The handling of large, thick mirrors presents unique challenges that highlight the strengths and limitations of both automated and manual approaches. Mirror loading and cutting machines have made significant strides in addressing the complexities associated with manipulating substantial glass panels.

Automated systems employ sophisticated vacuum suction technology and precision-guided robotic arms capable of safely lifting and maneuvering mirrors of considerable size and weight. These machines can handle mirrors measuring several meters in length and weighing hundreds of kilograms with remarkable ease and precision. The risk of damage during the loading process is minimized through carefully calibrated pressure control and soft-touch gripping mechanisms.

In contrast, manual handling of large, thick mirrors is a labor-intensive and potentially hazardous process. It typically requires multiple workers and specialized lifting equipment, increasing the risk of workplace injuries and mirror damage. The physical strain involved in manually manipulating heavy glass panels can lead to fatigue-related errors, particularly during extended production shifts.

Automated systems also excel in maintaining consistent handling procedures across different mirror sizes and thicknesses. They can be programmed to adjust their grip strength, lifting speed, and positioning based on the specific characteristics of each mirror. This adaptability ensures that both delicate thin mirrors and robust thick panels receive appropriate handling, minimizing the risk of breakage or surface damage.

Furthermore, mirror loading and cutting machines offer superior stability during the cutting process. Large mirrors, when manually handled, are susceptible to vibrations and slight movements that can affect cutting accuracy. Automated systems, equipped with advanced stabilization mechanisms, maintain perfect stillness during the cutting operation, ensuring clean, precise edges even on the largest mirror panels.

Assessing the return on investment (ROI) for automation

Evaluating the financial implications of implementing automated mirror loading and cutting technology is a critical consideration for manufacturers. While the initial investment in these advanced systems can be substantial, the long-term benefits often translate into significant cost savings and improved operational efficiency.

One of the most immediate and quantifiable returns comes from increased productivity. A single mirror loading and cutting machine from Customized mirror loading and cutting machine manufacturers can often replace multiple manual workstations, dramatically increasing throughput. These systems can operate continuously with minimal downtime, potentially doubling or even tripling production capacity compared to manual methods.

Material waste reduction represents another substantial area of cost savings. The precision cutting capabilities of automated systems typically result in material waste reductions of 15-20% compared to manual cutting methods. For large-scale operations processing thousands of square meters of mirror annually, this reduction in waste can translate to significant cost savings on raw materials.

Labor cost considerations play a crucial role in ROI calculations. While automated systems require skilled operators and maintenance technicians, they significantly reduce the overall labor requirements for mirror processing. This reduction not only lowers direct labor costs but also minimizes associated expenses such as training, insurance, and potential workplace injury claims.

Quality improvements and reduced rework rates contribute substantially to the long-term ROI. The consistency and precision of automated cutting lead to fewer rejected pieces and customer returns, enhancing brand reputation and customer satisfaction. This improved quality control can open doors to higher-value contracts and markets that demand exacting standards.

Energy efficiency is another factor that impacts ROI. Modern mirror loading and cutting machines are designed with energy-saving features, often consuming less power per unit produced compared to traditional manual cutting setups. Over time, these energy savings can accumulate into substantial cost reductions, particularly in regions with high electricity costs.

While the upfront costs of automation can be daunting, many manufacturers find that the break-even point is reached within 2-3 years of implementation. Beyond this point, the ongoing savings and increased production capacity continue to deliver value, making automated systems a sound long-term investment for many operations.

Conclusion

The transition from manual to automated mirror loading and cutting processes represents a significant leap forward in manufacturing technology. While manual methods still have their place in certain niche applications, the overwhelming advantages of automation in terms of precision, efficiency, and handling capability make it an increasingly attractive option for manufacturers looking to stay competitive in a rapidly evolving industry.

For companies considering this technological upgrade, it's crucial to partner with experienced and reputable equipment providers. Shandong Huashil Automation Technology Co., LTD stands at the forefront of this revolution, offering cutting-edge mirror loading and cutting machines tailored to meet the diverse needs of modern glass manufacturers. With years of expertise in automated R&D, manufacturing, and sales, we deliver solutions that combine advanced technology, robust reliability, and exceptional service.

Ready to transform your mirror production process? Contact our team of experts today at salescathy@sdhuashil.com to discover how our state-of-the-art mirror loading and cutting machines can elevate your manufacturing capabilities to new heights. Let's work together to optimize your production, reduce costs, and set new standards in mirror quality and precision.

References

1. Johnson, A. R. (2022). "Advancements in Automated Glass Processing: A Comprehensive Review." Journal of Industrial Automation, 45(3), 287-302.

2. Smith, B. T., & Lee, C. K. (2023). "Comparative Analysis of Manual vs. Automated Mirror Cutting Techniques." International Journal of Manufacturing Engineering, 18(2), 112-128.

3. Chen, X., & Wong, Y. S. (2021). "Economic Implications of Implementing Automated Glass Cutting Systems in Medium-Scale Industries." Asian Journal of Industrial Technology, 33(4), 551-567.

4. Patel, R. V., & Müller, H. (2022). "Precision and Efficiency in Modern Mirror Manufacturing: An Industry Perspective." European Glass Technology Review, 29(1), 75-91.