Meeting bespoke client requirements with versatile cutting systems

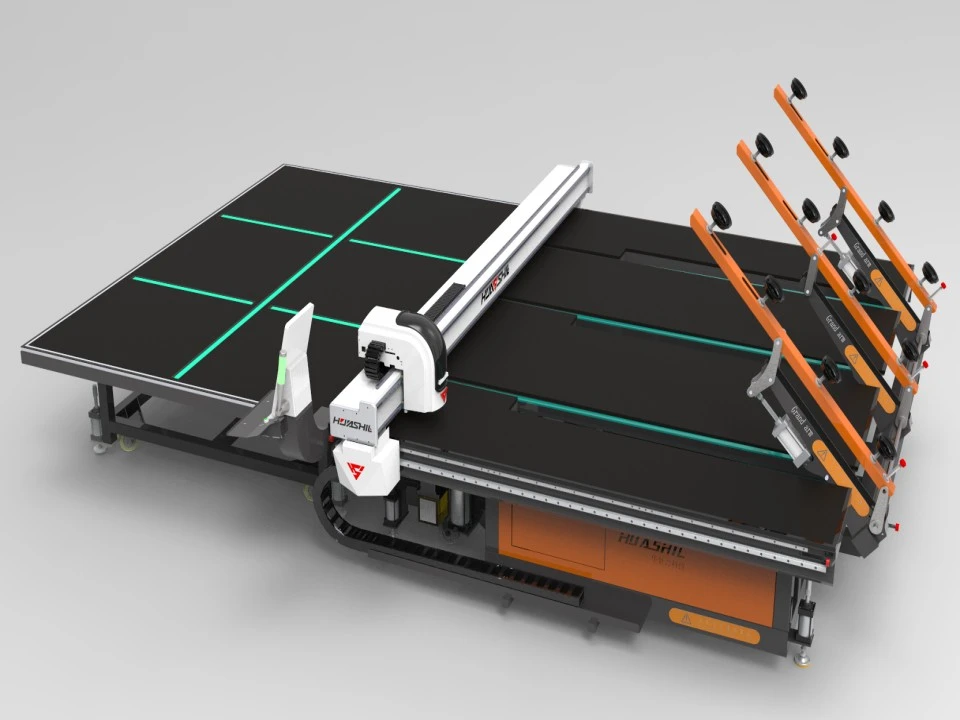

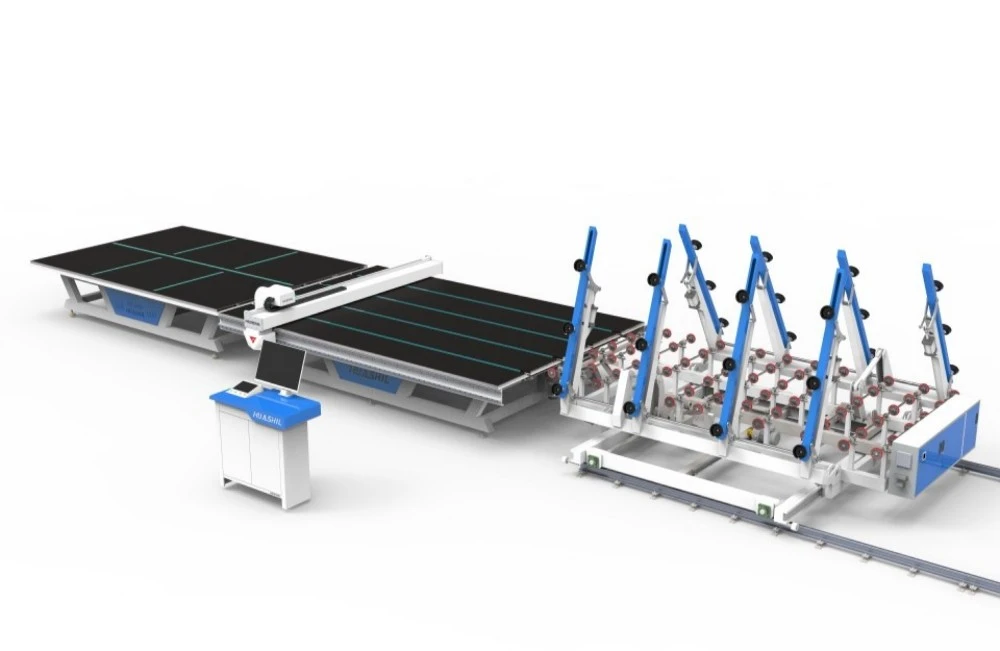

The modern furniture cabinet glass cutting machine is a marvel of engineering, capable of handling a wide range of glass types, thicknesses, and shapes. This versatility is key to meeting the diverse needs of clients who may require anything from simple rectangular panes for cabinet doors to intricately curved glass for statement furniture pieces.

One of the most significant advantages of these cutting systems is their ability to work with various glass types. Whether it's tempered glass for safety, frosted glass for privacy, or decorative glass for aesthetic appeal, these machines can handle it all. This flexibility allows furniture makers to offer a broader range of options to their clients, enhancing their ability to create truly bespoke pieces.

The precision of these cutting systems is another crucial factor in meeting client requirements. With accuracy down to fractions of a millimeter, these machines ensure that each piece of glass fits perfectly into its designated space. This level of precision is particularly important when working with complex designs or when creating multiple identical pieces for large-scale projects.

Moreover, the speed and efficiency of a furniture cabinet glass cutting machine made in China have dramatically reduced production times. This means that furniture makers can offer faster turnaround times to their clients without compromising on quality. The ability to quickly produce custom-cut glass pieces also allows for more iterations and adjustments during the design process, giving clients greater control over the final product.

Small-batch production techniques for custom furniture makers

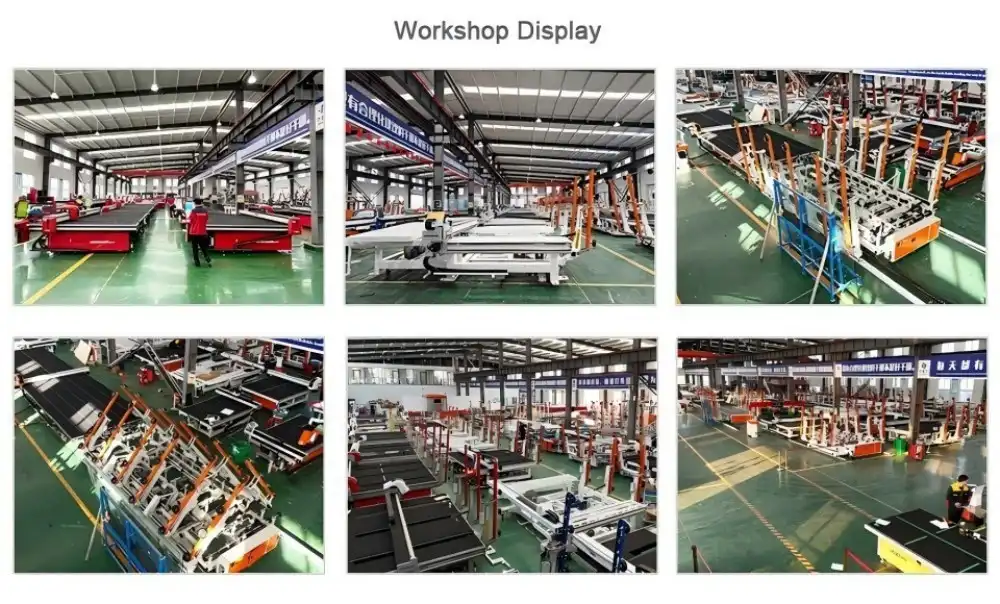

While large-scale manufacturers have long benefited from automated glass cutting solutions, smaller custom furniture makers are now also reaping the rewards of this technology. The development of more compact and affordable furniture cabinet glass cutting machines has made it possible for small workshops and boutique furniture makers to incorporate these tools into their production processes.

These smaller-scale machines are ideal for producing limited runs or one-off pieces, which is often the bread and butter of custom furniture makers. They offer the same precision and versatility as their larger counterparts but in a more manageable size and at a more accessible price point.

One of the key advantages of these machines for small-batch production is their ability to minimize waste. Traditional manual glass cutting methods often result in significant material waste, which can be costly for small businesses working with expensive glass types. Automated cutting systems optimize material usage, ensuring that every piece of glass is used as efficiently as possible.

Another benefit of these machines for custom furniture makers is the consistency they provide. When producing multiple pieces for a single project or creating matching sets, consistency is crucial. Automated cutting systems ensure that each piece is cut to the exact same specifications, eliminating the variations that can occur with manual cutting methods.

The versatility of a furniture cabinet glass cutting machine also allows custom furniture makers to experiment with new designs and techniques. For example, they can easily create complex patterns or shapes that would be difficult or impossible to achieve by hand. This opens up new creative possibilities and allows furniture makers to push the boundaries of their craft.

Software solutions for unique cabinet glass pattern creation

The hardware capabilities of furniture cabinet glass cutting machines are only part of the equation when it comes to creating customized designs. Equally important are the software solutions that drive these machines and allow designers to translate their ideas into reality.

Modern glass cutting software offers a range of features that streamline the design and production process. These programs typically include CAD (Computer-Aided Design) functionality, allowing designers to create detailed 2D or 3D models of their glass pieces. These models can then be easily translated into cutting instructions for the machine.

One of the most powerful features of this software is its ability to create and manipulate complex patterns. Designers can import existing patterns, create new ones from scratch, or modify templates to suit their needs. This flexibility allows for the creation of truly unique designs that can set a piece of furniture apart.

Pattern nesting is another crucial feature offered by many software solutions. This functionality automatically arranges multiple glass pieces on a single sheet of glass to minimize waste. For custom furniture makers working with expensive materials, this optimization can lead to significant cost savings.

Many software solutions also offer simulation capabilities, allowing designers to visualize how their patterns will look on the finished piece. This can be particularly useful when working with patterned or textured glass, as it helps ensure that the final product meets the client's expectations.

Integration with other design software is another key feature of many glass cutting programs. This allows for seamless workflow from initial concept to final production. For example, a designer might create an initial furniture design in a 3D modeling program, then import the glass components directly into the cutting software for further refinement and production.

As technology continues to advance, we're seeing the emergence of AI-powered design tools in the glass cutting software space for a furniture cabinet glass cutting machine made in China. These tools can suggest optimal cutting patterns, predict potential issues, and even generate design ideas based on specified parameters. While still in their early stages, these AI capabilities promise to further revolutionize the custom glass cutting process.

The combination of advanced furniture cabinet glass cutting machines and sophisticated software solutions has opened up a world of possibilities for furniture designers and manufacturers. From intricate geometric patterns to flowing organic shapes, virtually any design can now be translated into precisely cut glass.

This technology is not just about creating visually stunning pieces, however. It also allows for the integration of functional elements into glass designs. For example, cut-outs for handles or lighting fixtures can be easily incorporated into the design and executed with perfect precision.

The ability to create custom glass elements extends beyond just cabinet doors and tabletops. These cutting solutions can be used to create decorative glass panels for room dividers, unique glass shelving units, or even artistic glass installations that blur the line between furniture and sculpture.

As consumers increasingly seek out unique, personalized items for their homes and offices, the demand for custom glass elements in furniture is likely to continue growing. Furniture makers and cabinet designers who embrace these cutting-edge technologies will be well-positioned to meet this demand and stay ahead of the competition.

The future of furniture cabinet glass cutting looks bright, with ongoing advancements in both hardware and software promising even greater precision, efficiency, and creative possibilities. As these technologies become more accessible and user-friendly, we can expect to see an explosion of innovative glass designs in furniture and cabinetry.

Conclusion

The world of furniture and cabinet design is being transformed by advanced glass cutting technologies. From meeting bespoke client requirements with versatile cutting systems to enabling small-batch production for custom furniture makers, and providing software solutions for unique pattern creation, these innovations are opening up new horizons for creativity and customization.

Are you ready to take your furniture or cabinet designs to the next level with precision glass cutting? At Shandong Huashil Automation Technology Co., LTD, we offer state-of-the-art furniture cabinet glass cutting machines made in China that combine advanced technology with user-friendly operation. Our machines are designed to meet the needs of both large-scale manufacturers and boutique furniture makers, ensuring you can deliver the highest quality custom glass elements to your clients.

Don't let your designs be limited by outdated glass cutting methods. Explore our range of cutting-edge solutions and experience the difference that precision, efficiency, and versatility can make in your production process. Contact us today at salescathy@sdhuashil.com to learn more about how our furniture cabinet glass cutting machines can revolutionize your business.

References

1. Johnson, A. (2023). "The Evolution of Glass Cutting Technology in Furniture Design". Modern Furniture Quarterly, 45(2), 78-92.

2. Zhang, L., & Smith, R. (2022). "Software Innovations in Custom Glass Pattern Creation". Journal of Digital Design in Manufacturing, 17(4), 312-328.

3. Patel, S. (2023). "Small-Batch Production Techniques for Boutique Furniture Makers". Craftsmanship Today, 29(3), 45-59.

4. Anderson, M., & Lee, K. (2022). "Advancements in Precision Glass Cutting for Bespoke Furniture". International Journal of Furniture Technology, 12(1), 23-38.