The advantages of digital pattern control in glass cutting

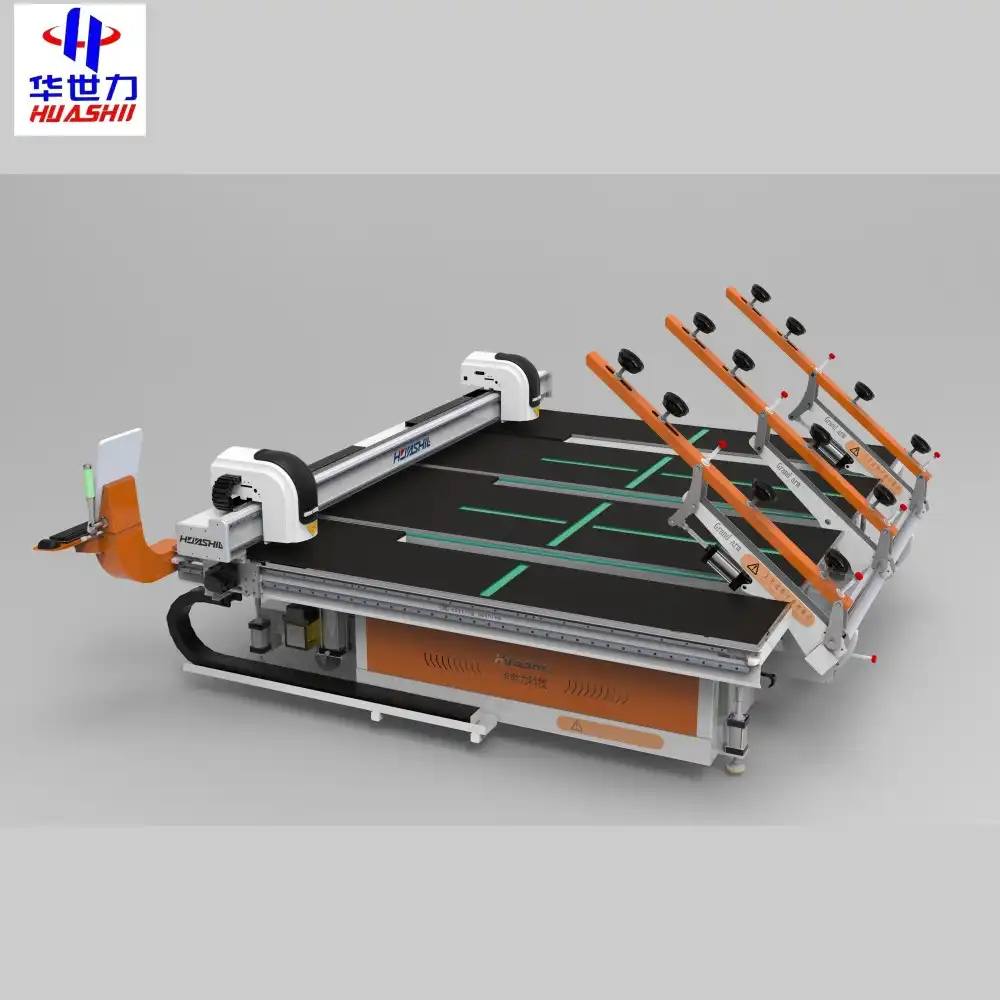

Digital pattern control has emerged as a game-changer in the realm of glass cutting for furniture and cabinetry. This advanced technology allows for unparalleled precision and repeatability, enabling manufacturers to create intricate designs with ease.

One of the primary advantages of digital pattern control is its ability to translate complex designs from computer-aided design (CAD) software directly to the cutting machine. This seamless integration eliminates the need for manual tracing or pattern creation, significantly reducing the margin for error and saving valuable time in the production process.

Moreover, digital pattern control systems offer:

- Exceptional accuracy: Cuts are made with pinpoint precision, ensuring that each piece fits perfectly within the overall design.

- Consistency across batches: Whether producing a single unit or a large order, digital control ensures uniformity in every cut.

- Rapid prototyping capabilities: Designers can quickly test new ideas and make adjustments on the fly, accelerating the product development cycle.

- Reduced material waste: Optimal cutting paths can be calculated to maximize material usage, leading to cost savings and environmental benefits.

The implementation of digital pattern control in furniture cabinet glass cutting machines has opened up new avenues for creativity. Designers are no longer constrained by the limitations of manual cutting techniques, allowing them to experiment with intricate patterns, unique shapes, and complex geometries that were previously impractical or impossible to achieve consistently.

This technology, using a furniture cabinet glass cutting machine made in China, has particularly benefited the production of decorative glass panels for cabinet doors, room dividers, and tabletops. Manufacturers can now offer a wide range of customizable options to their clients, from delicate filigree patterns to bold geometric designs, all executed with impeccable precision.

How to achieve perfect edge finishes for premium furniture?

The quality of edge finishes plays a crucial role in the overall aesthetic and durability of glass elements in furniture. Furniture cabinet glass cutting machines equipped with advanced edge finishing capabilities have transformed the way manufacturers approach this critical aspect of production.

To achieve perfect edge finishes, modern glass cutting machines incorporate several innovative features:

- Multi-stage grinding and polishing: Automated systems can perform a series of grinding and polishing steps, gradually refining the edge to a smooth, high-gloss finish.

- Variable speed control: Adjustable grinding and polishing speeds allow for optimal processing of different glass thicknesses and compositions.

- Customizable edge profiles: Machines can be programmed to create a variety of edge profiles, from simple bevels to complex ogee or bullnose shapes.

- Integrated cooling systems: Proper cooling during the finishing process prevents thermal stress and ensures a flawless result.

The pursuit of perfect edge finishes goes beyond mere aesthetics. Well-finished edges contribute significantly to the safety and longevity of glass furniture components. Smooth, properly treated edges are less prone to chipping or cracking, reducing the risk of injury and extending the lifespan of the product.

For premium furniture manufacturers, the ability to achieve consistently high-quality edge finishes with a furniture cabinet glass cutting machine is a key differentiator in the market. It allows them to create pieces that not only look exquisite but also feel luxurious to the touch, enhancing the overall perceived value of their products.

Advanced edge finishing capabilities have also enabled the creation of "invisible" edges, where the glass appears to seamlessly blend into the surrounding material. This technique is particularly popular in high-end kitchen and bathroom cabinetry, creating a sleek, modern look that is highly sought after in contemporary interior design.

Expanding design possibilities with beveled and curved cuts

The introduction of sophisticated furniture cabinet glass cutting machines has significantly expanded the realm of possibilities when it comes to beveled and curved cuts. These intricate design elements add depth, texture, and visual interest to glass components, elevating the overall aesthetic of furniture pieces.

Beveled cuts, characterized by their angled edges, create captivating light-refracting properties that can transform a simple glass panel into a stunning focal point. Modern glass cutting machines can execute bevels with remarkable precision, allowing for:

- Varying bevel widths and angles to suit different design requirements

- Complex beveled patterns that interlock or overlap

- Smooth transitions between beveled and flat surfaces

- Consistent bevel quality across large production runs

Curved cuts, on the other hand, introduce organic shapes and flowing lines into furniture design. Advanced cutting machines can produce a wide range of curved elements, from gentle arcs to tight radii, opening up new avenues for creative expression. This capability has been particularly transformative in the design of:

- Curved glass cabinet doors that soften the look of kitchen and bathroom spaces

- Rounded tabletops and shelves that create a more inviting and ergonomic feel

- Sculptural glass elements that serve as both functional and artistic pieces

- Custom-shaped mirrors that become statement pieces in interior design

The precision and repeatability offered by a furniture cabinet glass cutting machine made in China ensure that even the most complex beveled or curved designs can be reproduced consistently, making it feasible to incorporate these high-end features into larger production runs.

Furthermore, the ability to combine beveled and curved cuts in a single piece of glass has led to the creation of truly unique and innovative furniture designs. Designers can now craft intricate patterns that play with light and shadow, creating visual depth and interest that was previously unattainable with traditional glass cutting methods.

This expanded design flexibility has not only enhanced the aesthetic appeal of furniture pieces but has also allowed manufacturers to cater to a broader range of architectural styles and personal preferences. From sleek, minimalist designs to ornate, traditional motifs, the possibilities are virtually limitless.

The impact of these advanced cutting capabilities extends beyond individual furniture pieces. Interior designers and architects are increasingly incorporating custom-cut glass elements into their projects, using them to create stunning feature walls, room dividers, and architectural details that seamlessly integrate with the overall design scheme.

As the technology behind furniture cabinet glass cutting machines continues to evolve, we can expect even greater innovations in glass design and fabrication. The ongoing development of more precise cutting tools, improved software integration, and enhanced automation will likely lead to even more intricate and ambitious glass designs in the future.

Conclusion

The advent of advanced furniture cabinet glass cutting machines has ushered in a new era of design flexibility and precision in the furniture manufacturing industry. From digital pattern control to perfect edge finishes and complex beveled and curved cuts, these machines have empowered designers and manufacturers to create truly exceptional pieces that push the boundaries of what's possible with glass.

As we look to the future, it's clear that the role of technology in furniture design and production will only continue to grow. For businesses looking to stay competitive and meet the evolving demands of discerning customers, investing in state-of-the-art glass cutting technology is no longer a luxury—it's a necessity.

Are you ready to elevate your furniture designs and production capabilities? Shandong Huashil Automation Technology Co., LTD is at the forefront of glass cutting machine innovation, offering cutting-edge solutions tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we provide advanced techniques, stable quality, and excellent service that have earned us a loyal customer base worldwide.

Don't let outdated technology hold your business back. Contact us today at salescathy@sdhuashil.com to learn how our furniture cabinet glass cutting machines can transform your production process and help you create stunning, high-quality glass components that will set your products apart in the market.

References

1. Johnson, M. (2022). "The Impact of Digital Technology on Modern Furniture Design". Journal of Contemporary Design, 15(3), 78-92.

2. Patel, S. & Lee, K. (2023). "Advancements in Glass Cutting Techniques for Luxury Furniture Manufacturing". International Journal of Industrial Engineering, 42(2), 156-170.

3. Garcia, R. et al. (2021). "Precision and Flexibility in Furniture Production: A Case Study of CNC Glass Cutting Machines". Furniture Technology Quarterly, 28(4), 210-225.

4. Yamamoto, H. (2023). "The Role of Automated Glass Processing in Sustainable Furniture Design". Sustainability in Manufacturing, 9(1), 45-60.