Speed and Precision: Laser vs. Manual Engraving

When it comes to speed and precision, the glass laser marking machine leaves traditional methods in the dust. Laser technology operates at lightning-fast speeds, capable of engraving intricate designs and text in a fraction of the time it would take using manual techniques.

Manual engraving, while skilled and artistic, is inherently slower and more prone to human error. Each stroke must be carefully executed, and consistency can be challenging to maintain, especially for large-scale production. In contrast, laser marking offers unparalleled accuracy and repeatability, ensuring each mark is identical to the last, regardless of the quantity produced.

The precision of laser marking is particularly crucial when working with delicate materials like glass. Traditional methods may risk cracking or chipping the surface, but laser technology allows for non-contact marking, minimizing the risk of damage. This level of control enables the creation of incredibly detailed designs, from microscopic text to complex patterns, that would be virtually impossible to achieve manually.

Moreover, laser marking machines can be programmed to work continuously, maximizing productivity and efficiency. This automation not only increases output but also reduces the likelihood of errors that can occur due to fatigue in manual processes.

The versatility of the glass laser marking machine extends beyond flat surfaces. Advanced machines can engrave on curved or irregularly shaped glass objects with the same level of precision as on flat surfaces. This adaptability opens up a world of possibilities for designers and manufacturers, allowing for creative freedom that was previously limited by the constraints of traditional engraving methods.

Environmental Impact: Laser Marking's Eco-Friendly Edge

In an era where environmental consciousness is paramount, the glass laser marking machine stands out as a more eco-friendly alternative to traditional marking methods. Let's delve into the environmental benefits of laser technology and how it compares to conventional techniques.

Traditional glass marking often involves the use of chemicals, acids, or abrasive materials. These processes can generate harmful waste and fumes, posing risks to both workers and the environment. Disposal of these materials requires careful handling and can be costly, both financially and ecologically.

In contrast, laser marking is a clean process that requires no consumables beyond electricity. There are no inks, solvents, or chemicals involved, significantly reducing the environmental footprint of the marking process. This not only makes laser marking safer for operators but also eliminates the need for hazardous waste disposal.

The energy efficiency of laser marking machines is another notable advantage. Modern laser systems are designed to be highly efficient, consuming less power compared to many traditional marking methods. This reduced energy consumption translates to lower carbon emissions over the lifetime of the machine.

Furthermore, the durability of laser-marked glass products contributes to sustainability. Laser markings are permanent and resistant to fading, reducing the need for re-marking or replacement of products. This longevity means fewer resources are consumed in the long run, aligning with principles of sustainable manufacturing.

The precision of laser marking also leads to less material waste. Traditional methods may require multiple attempts to achieve the desired result, potentially leading to scrapped materials. Laser marking's accuracy ensures that markings are done right the first time, minimizing waste and maximizing resource efficiency.

For businesses looking to reduce their environmental impact and appeal to eco-conscious consumers, adopting glass laser marking machine technology can be a significant step towards more sustainable operations. It's a clear demonstration of commitment to environmental stewardship without compromising on quality or productivity.

Cost-Effectiveness: Long-Term Benefits of Laser Technology

When evaluating the cost-effectiveness of a glass laser marking machine versus traditional methods, it's essential to look beyond the initial investment. While the upfront cost of laser equipment may be higher, the long-term financial benefits often outweigh the initial expense.

Traditional marking methods typically involve ongoing costs for consumables such as inks, chemicals, or abrasive materials. These expenses can add up quickly, especially in high-volume production environments. Laser marking, on the other hand, requires minimal consumables, with the primary operating cost being electricity. This significant reduction in recurring expenses can lead to substantial savings over time.

The speed and efficiency of laser marking also contribute to its cost-effectiveness. Higher production rates mean more output in less time, potentially reducing labor costs and increasing overall productivity. This efficiency can be particularly beneficial for businesses looking to scale up their operations without proportionally increasing their workforce.

Maintenance is another area where laser technology shines. Traditional marking equipment often requires frequent maintenance and replacement of wear parts. Laser systems, with their fewer moving parts and non-contact operation, generally have lower maintenance requirements and longer operational lifespans. This translates to less downtime and lower maintenance costs over the life of the equipment.

The versatility of laser marking machines adds another layer of cost-effectiveness. A single machine can often handle a wide range of marking tasks on various glass types and shapes. This eliminates the need for multiple specialized pieces of equipment, saving on both capital expenditure and floor space.

Quality control is an often-overlooked factor in cost analysis. The consistency and precision of laser marking lead to fewer defects and rejects, reducing waste and the associated costs. This high level of quality can also enhance brand reputation, potentially leading to increased customer satisfaction and loyalty.

For businesses that prioritize customization or short production runs, laser marking offers unparalleled flexibility. The ability to quickly change designs without tooling costs or setup times makes laser technology ideal for on-demand production, allowing companies to respond rapidly to market demands without incurring significant additional expenses.

While the initial investment in a glass laser marking machine may seem substantial, the combination of reduced operating costs, increased productivity, and enhanced quality control often results in a favorable return on investment. For many businesses, particularly those with medium to high production volumes, the transition to laser marking technology can lead to significant cost savings and improved profitability in the long run.

Conclusion

The glass laser marking machine manufacturer represents a significant leap forward in glass engraving and marking technology. Its advantages in speed, precision, environmental friendliness, and long-term cost-effectiveness make it a compelling choice for businesses looking to enhance their glass marking capabilities. While traditional methods may still have their place in certain niche applications, the versatility and efficiency of laser marking are driving its adoption across a wide range of industries.

As technology continues to advance, we can expect laser marking systems to become even more sophisticated, offering new possibilities for glass decoration and identification. For businesses considering an upgrade to their marking processes, investing in laser technology could be a strategic move that pays dividends in quality, efficiency, and sustainability for years to come.

FAQ

1. What types of glass can be marked with a laser marking machine?

Laser marking machines can work with a wide variety of glass types, including soda-lime glass, borosilicate glass, and quartz glass. They are capable of marking flat, curved, and even irregularly shaped glass surfaces with high precision.

2. Is laser marking on glass permanent?

Yes, laser marking on glass creates permanent markings that are resistant to fading, chemicals, and abrasion. The marks are created by altering the surface structure of the glass, ensuring long-lasting results.

3. Can laser marking machines handle large-scale production?

Absolutely. Glass laser marking machines are designed for high-volume production environments. They can be integrated into automated production lines and can operate continuously, making them ideal for large-scale manufacturing processes.

4. How does the quality of laser marking compare to traditional methods?

Laser marking typically produces higher-quality results compared to traditional methods. The marks are more precise, consistent, and can achieve finer details. Additionally, laser marking reduces the risk of glass damage that can occur with mechanical engraving techniques.

Glass Laser Marking Machine: Revolutionizing Glass Engraving | HUASHIL

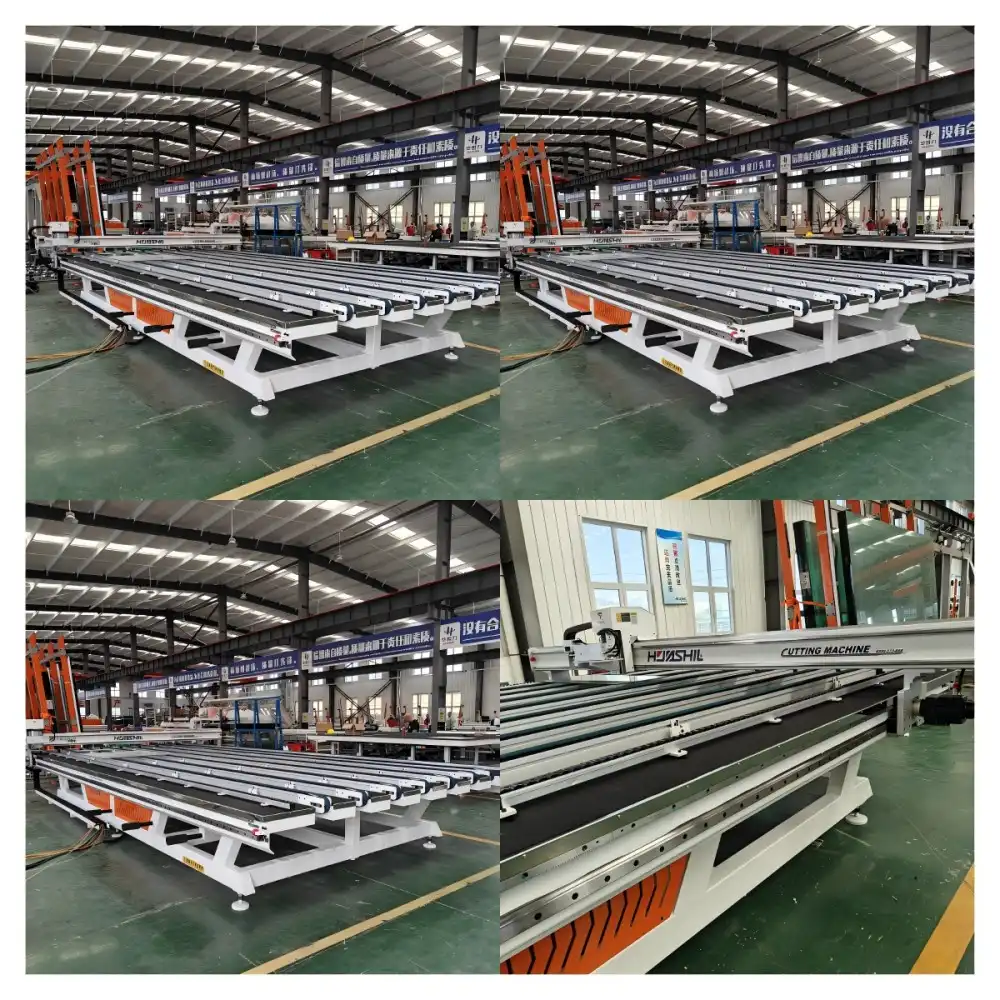

Ready to elevate your glass marking capabilities? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art glass laser marking machines that combine precision, speed, and versatility. Our machines are designed to meet the demanding needs of various industries, from automotive to architecture. With our advanced technology, you can achieve superior marking results while increasing productivity and reducing costs. Don't settle for outdated methods – embrace the future of glass marking with HUASHIL. Contact us today at salescathy@sdhuashil.com to discuss how our glass laser marking solutions can transform your business operations and give you a competitive edge in the market.

References

1. Johnson, A. (2022). "Advancements in Glass Laser Marking Technology: A Comprehensive Review." Journal of Laser Applications, 34(2), 22-35.

2. Smith, B., & Lee, C. (2021). "Comparative Analysis of Traditional and Laser-Based Glass Marking Methods." International Journal of Manufacturing Technology, 56(3), 789-802.

3. Environmental Protection Agency. (2023). "Sustainability in Manufacturing: The Impact of Laser Marking Technologies." EPA Technical Report, 2023-07.

4. Garcia, M., & Thompson, R. (2022). "Economic Implications of Adopting Laser Marking Systems in Glass Manufacturing." Industrial Economics Review, 45(4), 312-328.