Glass cutting equipment plays a pivotal role in various industries, from architectural glass manufacturing to automotive and decorative glass production. To ensure these machines continue to deliver precise cuts and maintain their efficiency, routine maintenance is essential. This comprehensive guide will explore the key aspects of maintaining glass cutting equipment, helping you maximize performance and longevity.

Daily checks: Ensuring optimal cutting performance

Daily maintenance routines are crucial for keeping your glass cutting equipment in top condition. These checks help identify potential issues before they escalate into major problems, ensuring consistent cutting quality and minimizing downtime.

Inspect cutting wheels

The cutting wheel is the heart of your glass cutting machine. Start each day by examining the cutting wheel for signs of wear or damage. Look for chips, cracks, or uneven edges that could compromise cutting precision. Replace the wheel if you notice any defects to maintain optimal performance.

Clean the cutting surface

A clean cutting surface is essential for accurate cuts. Remove any glass debris, dust, or residue from the cutting table using a soft brush or compressed air. Pay special attention to the scoring line area, as accumulated debris can affect cutting quality.

Check fluid levels

Many glass cutting machines use glass cutting equipment cutting fluids to lubricate the cutting wheel and improve cut quality. Check the fluid levels daily and top up if necessary. Use the manufacturer-recommended cutting fluid to ensure optimal performance and prevent damage to the equipment.

Examine belts and bearings

Inspect drive belts for signs of wear, fraying, or looseness. Check bearings for smooth operation and proper lubrication. Addressing these components early can prevent unexpected breakdowns and maintain cutting accuracy.

Verify alignment

Ensure that all components are properly aligned. This includes the cutting bridge, vacuum cups (if applicable), and positioning systems. Misalignment can lead to inaccurate cuts and increased waste.

Scheduled maintenance: Prolonging equipment lifespan

While daily checks are crucial, scheduled maintenance tasks are equally important for the long-term health of your glass cutting equipment. These periodic maintenance activities help prevent wear and tear, optimize performance, and extend the lifespan of your machine.

Lubricate moving parts

Regular lubrication of moving parts is essential for smooth operation and preventing premature wear. Follow the manufacturer's guidelines for lubrication schedules and recommended lubricants. Pay attention to bearings, linear guides, and other friction points.

Calibrate sensors and positioning systems

Accurate glass cutting relies on precise positioning and measurement. Regularly calibrate sensors, encoders, and positioning systems to ensure they maintain their accuracy over time. This may require specialized tools or professional assistance, depending on the complexity of your equipment.

Update software and firmware

For CNC glass cutting machines, keeping the software and firmware up to date is crucial. These updates often include bug fixes, performance improvements, and new features that can enhance your machine's capabilities and efficiency.

Inspect and replace wear parts

Certain components of your glass cutting equipment are subject to wear and will need periodic replacement. This may include cutting wheels, scoring wheels, vacuum cups, and conveyor belts. Establish a replacement schedule based on the manufacturer's recommendations and your usage patterns.

Clean and maintain electrical components

Dust and debris can accumulate in electrical cabinets and control panels, potentially leading to overheating or malfunctions. Regularly clean these areas using appropriate methods, such as compressed air or specialized electronic cleaning products. Check for loose connections and tighten as needed.

Evaluate machine geometry

Over time, the geometry of your glass cutting machine may drift, affecting cutting accuracy. Periodically check and adjust the machine's geometry, including the flatness of the cutting table, the squareness of the cutting bridge, and the parallelism of linear guides.

Troubleshooting common glass cutter issues

Even with diligent maintenance, glass cutting equipment may occasionally experience issues. Being able to quickly identify and resolve these problems can minimize downtime and maintain productivity.

Poor cut quality

If you notice rough or incomplete cuts, several factors could be at play:

- Dull or damaged cutting wheel: Replace the wheel if it shows signs of wear.

- Incorrect cutting pressure: Adjust the pressure according to the glass thickness and type.

- Contaminated cutting surface: Clean the cutting table thoroughly.

- Inadequate cutting fluid: Check fluid levels and quality.

Inconsistent measurements

When cut glass pieces don't match the programmed dimensions, consider the following:

- Sensor calibration: Recalibrate positioning sensors and encoders.

- Software issues: Check for and install any available updates.

- Mechanical wear: Inspect linear guides and drive systems for signs of wear.

Unusual noises or vibrations

Abnormal sounds or vibrations during operation can indicate:

- Loose components: Check and tighten all bolts and connections.

- Worn bearings: Inspect and replace bearings if necessary.

- Misalignment: Verify and adjust the alignment of moving parts.

Vacuum system failures

If your glass cutting equipment uses a vacuum system for glass handling, issues may arise:

- Leaks: Check vacuum cups and hoses for damage or wear.

- Clogged filters: Clean or replace vacuum filters regularly.

- Pump issues: Inspect and maintain the vacuum pump according to manufacturer guidelines.

Electrical malfunctions

Electrical problems can manifest in various ways:

- Power fluctuations: Install a voltage stabilizer if power supply is inconsistent.

- Control panel errors: Document error codes and consult the manual or manufacturer for resolution.

- Sensor failures: Test and replace faulty sensors as needed.

Software glitches

CNC glass cutting machines may experience software-related issues:

- Program crashes: Ensure your system meets the software's requirements and install updates.

- Communication errors: Check connections between the computer and the machine controller.

- Corrupt files: Maintain backups of cutting programs and machine settings.

Implementing a preventive maintenance schedule

To maximize the efficiency and lifespan of your glass cutting equipment, it's crucial to implement a comprehensive preventive maintenance schedule. This proactive approach can help you avoid unexpected breakdowns, reduce repair costs, and maintain consistent cutting quality.

Create a maintenance calendar

Develop a detailed maintenance calendar that outlines daily, weekly, monthly, and annual tasks. Include all aspects of your glass cutting equipment, from mechanical components to electrical systems and software. Assign responsibilities to specific team members to ensure accountability.

Document maintenance activities

Keep thorough records of all maintenance activities performed on your equipment. This documentation can help identify recurring issues, track component lifespans, and provide valuable information for troubleshooting and future maintenance planning.

Train operators and maintenance staff

Invest in comprehensive training for your equipment operators and maintenance personnel. Ensure they understand the importance of routine maintenance and can perform basic troubleshooting. This knowledge can help prevent minor issues from escalating into major problems.

Stock essential spare parts

Maintain an inventory of critical spare parts to minimize downtime in case of component failure. This may include cutting wheels, bearings, belts, and other frequently replaced items. Regularly review and replenish your spare parts inventory based on usage patterns and manufacturer recommendations.

Utilize predictive maintenance techniques

Consider implementing predictive maintenance techniques to identify potential issues before they lead to equipment failure. This may involve using sensors to monitor equipment performance, analyzing vibration patterns, or conducting regular oil analysis to detect early signs of wear.

Optimizing cutting fluid management

Proper management of cutting fluids is crucial for maintaining the performance and longevity of your glass cutting equipment. These fluids play a vital role in lubricating the cutting wheel, dissipating heat, and removing glass particles during the cutting process.

Choose the right cutting fluid

Select a cutting fluid that is compatible with your equipment and suitable for the types of glass you process. Consider factors such as viscosity, cooling properties, and environmental impact when choosing a cutting fluid.

Monitor fluid quality

Regularly test the quality of your cutting fluid to ensure it maintains its effectiveness. Check for contamination, pH levels, and concentration (for water-soluble fluids). Replace or recondition the fluid as needed to maintain optimal cutting performance.

Implement a filtration system

Install and maintain an effective filtration system to remove glass particles and other contaminants from the cutting fluid. This helps extend the life of the fluid and prevents damage to your equipment caused by abrasive particles.

Proper storage and handling

Store cutting fluids in appropriate containers and conditions to prevent contamination and degradation. Train your staff on proper handling procedures to minimize the risk of spills and ensure consistent fluid quality.

Enhancing operator skills and awareness

Well-trained operators are essential for maintaining the performance and longevity of your glass cutting equipment. Investing in ongoing training and fostering a culture of equipment care can significantly impact your maintenance efforts.

Develop comprehensive training programs

Create detailed training programs that cover all aspects of operating and maintaining your glass cutting equipment. Include both theoretical knowledge and hands-on practice to ensure operators are fully prepared for their roles.

Encourage proactive reporting

Foster an environment where operators feel comfortable reporting any unusual sounds, vibrations, or performance issues they notice during operation. Early detection of potential problems can prevent more serious damage and reduce downtime.

Implement standard operating procedures

Develop and enforce standard operating procedures (SOPs) for equipment use, maintenance, and troubleshooting. Clear guidelines help ensure consistency in equipment care across different shifts and operators.

Regular skill assessments

Conduct periodic skill assessments to identify areas where operators may need additional training or support. This can help maintain a high level of competence and prevent errors that could lead to equipment damage.

Leveraging technology for maintenance management

Modern technology offers numerous tools and solutions to streamline and improve the maintenance of your glass cutting equipment factory. Implementing these technologies can enhance efficiency, reduce human error, and provide valuable insights into your equipment's performance.

Computerized Maintenance Management Systems (CMMS)

Implement a CMMS to schedule, track, and manage all aspects of your maintenance activities. These systems can help you automate work orders, track inventory, and generate reports to optimize your maintenance strategy.

IoT sensors and monitoring

Utilize Internet of Things (IoT) sensors to continuously monitor key parameters of your glass cutting equipment. This real-time data can help you detect anomalies early and implement predictive maintenance strategies.

Augmented reality for maintenance support

Consider using augmented reality (AR) tools to provide visual guidance for maintenance tasks. This technology can help technicians perform complex procedures more accurately and efficiently.

Data analytics for performance optimization

Leverage data analytics tools to analyze equipment performance data, identify trends, and make data-driven decisions about maintenance and optimization strategies.

Conclusion

Maintaining glass cutting equipment is a multifaceted task that requires attention to detail, consistency, and a proactive approach. By implementing a comprehensive maintenance strategy that includes daily checks, scheduled maintenance, and leveraging modern technologies, you can significantly extend the lifespan of your equipment, improve cutting quality, and minimize costly downtime.

Remember that each piece of glass cutting equipment may have specific maintenance requirements, so always consult your manufacturer's guidelines for detailed instructions. With proper care and maintenance, your glass cutting equipment will continue to deliver precise, high-quality cuts for years to come.

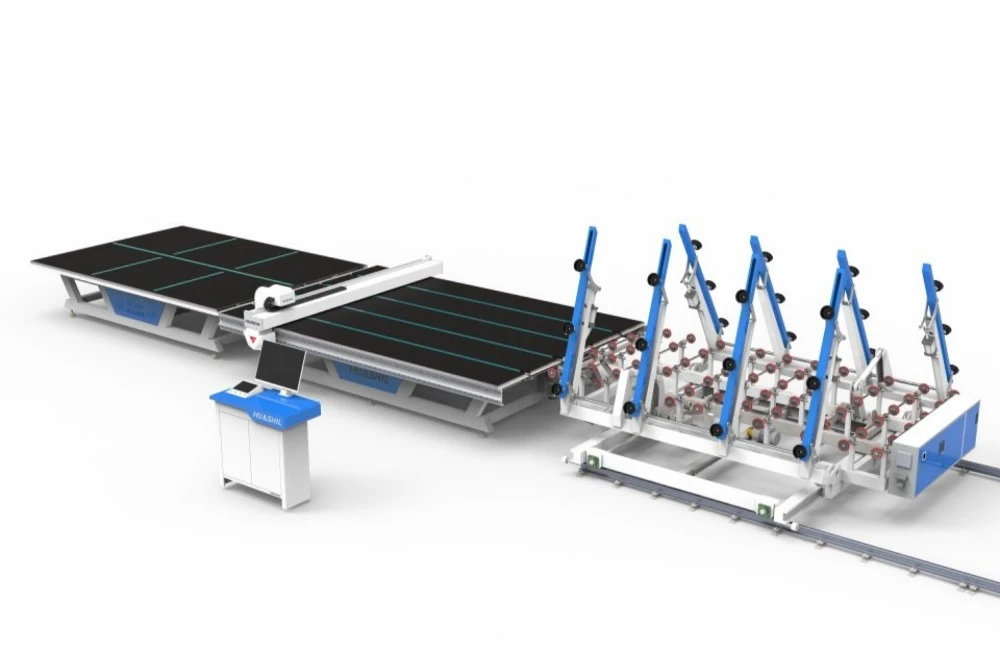

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that well-maintained glass cutting equipment plays in your production processes. Our team of experts is dedicated to providing you with top-quality glass processing solutions that are built to last. We offer comprehensive support and guidance to help you implement effective maintenance strategies tailored to your specific needs.

Whether you're looking to upgrade your existing equipment or seeking advice on optimizing your maintenance procedures, we're here to help. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us uniquely to address your glass cutting challenges.

Don't let equipment maintenance concerns hold back your productivity. Contact us today at salescathy@sdhuashil.com to learn how we can support your glass cutting operations with our advanced technology and expertise. Let's work together to keep your production running smoothly and efficiently.

References

1. Smith, J. (2023). "Preventive Maintenance Strategies for Glass Cutting Equipment". Journal of Glass Technology, 45(2), 78-92.

2. Johnson, R. & Lee, S. (2022). "Optimizing Cutting Fluid Management in Glass Processing". International Glass Review, 18(4), 112-125.

3. Brown, A. et al. (2023). "The Impact of Operator Training on Glass Cutting Equipment Longevity". Glass Industry Quarterly, 37(1), 23-36.

4. Garcia, M. (2022). "Leveraging IoT for Predictive Maintenance in Glass Manufacturing". Smart Factory Journal, 9(3), 55-68.