The Science Behind Automated Glass Fragmentation

At the heart of the glass recycling revolution lies the sophisticated technology of automatic glass breaking machines. These marvels of engineering employ a combination of mechanical force and precision control to shatter glass into uniform, recyclable fragments. The process begins with a carefully calibrated feed system that introduces glass items into the machine at a controlled rate.

Once inside, the glass encounters a series of hammers or impactors. These components are designed to deliver precise, high-speed blows to the glass, causing it to fracture along predetermined stress points. The machine's interior is lined with specially designed surfaces that further aid in breaking the glass while containing the fragments.

One of the key innovations in modern glass breaking machines is the incorporation of sensors and computer-controlled systems. These advanced features allow for real-time adjustments to the breaking process based on the type, thickness, and composition of the glass being processed. This adaptability ensures optimal fragmentation across a wide range of glass products, from bottles to window panes.

The resulting glass cullet – small, uniformly sized pieces of broken glass – is then sorted by color and quality. This sorting process, often automated as well, is crucial for producing high-quality recycled glass that can be used in various applications. The precision of automatic glass breakers ensures that the cullet is of consistent size and free from contaminants, making it ideal for reprocessing.

Efficiency Boost: From Manual to Machine-Driven Recycling

The transition from manual glass breaking to automated systems represents a quantum leap in recycling efficiency. Traditional methods of glass breaking were labor-intensive, time-consuming, and often resulted in inconsistent fragment sizes. Automatic glass breaking machines have revolutionized this process, offering numerous advantages:

- Increased Processing Speed: These machines can process tons of glass per hour, far surpassing manual capabilities. This high-speed operation allows recycling facilities to handle larger volumes of glass waste, reducing backlogs and increasing overall recycling rates.

- Improved Safety: By automating the breaking process, these machines significantly reduce the risk of injuries associated with manual glass handling. Workers are no longer exposed to sharp edges and flying glass shards, creating a safer work environment.

- Consistency in Output: Automated systems produce glass cullet of uniform size and quality. This consistency is crucial for downstream recycling processes, as it allows for more efficient melting and reforming of the glass into new products.

- Reduced Labor Costs: While initial investment in an automatic glass breaker may be substantial, the long-term savings in labor costs are significant. These machines can operate continuously with minimal human intervention, freeing up workers for other tasks.

- Enhanced Sorting Capabilities: Many modern glass breaking machines are equipped with advanced sorting technologies. These can separate glass by color and remove contaminants, further streamlining the recycling process.

The efficiency gains provided by automatic glass breakers extend beyond the immediate recycling process. By producing higher quality cullet, these machines contribute to energy savings in glass manufacturing. Recycled glass melts at a lower temperature than raw materials, reducing energy consumption in furnaces. This not only cuts costs but also decreases the carbon footprint of glass production.

Moreover, the speed and efficiency of these machines allow recycling facilities to process a wider range of glass products. Items that were once challenging to recycle, such as tempered glass or mixed-color glass, can now be handled more effectively. This expanded capability encourages more comprehensive glass recycling programs, potentially increasing the overall recycling rate in communities.

Environmental Impact: Reduced Landfill, Increased Reuse

The environmental benefits of automatic glass breaking machines are profound and far-reaching. By dramatically improving the efficiency and effectiveness of glass recycling, these machines play a crucial role in reducing the environmental impact of glass waste:

- Landfill Diversion: With increased recycling capacity, more glass is diverted from landfills. Glass is non-biodegradable and can persist in landfills for thousands of years. By breaking it down and recycling it, we significantly reduce the volume of waste in our landfills.

- Conservation of Raw Materials: Every ton of recycled glass means a ton less of raw materials need to be extracted from the earth. This conservation of natural resources helps protect ecosystems and reduces the environmental impact of mining and quarrying activities.

- Energy Savings: Using recycled glass in manufacturing requires less energy than starting with raw materials. This energy saving translates to reduced greenhouse gas emissions and a lower carbon footprint for the glass industry as a whole.

- Water Conservation: The glass recycling process uses significantly less water compared to manufacturing new glass from raw materials. This water saving is particularly important in regions facing water scarcity.

- Reduction in Air Pollution: By reducing the need for new glass production, recycling helps decrease air pollutants associated with the manufacturing process, including sulfur dioxide and nitrogen oxides.

The environmental benefits extend beyond the immediate recycling process. The high-quality cullet produced by automatic glass breakers can be used in a variety of applications beyond traditional glass manufacturing. For instance, it can be used in the production of fiberglass insulation, reducing the energy needs of buildings. It's also used in road construction as a substitute for sand, reducing the need for this increasingly scarce resource.

Furthermore, the efficiency of these machines encourages more comprehensive glass recycling programs. Municipalities and waste management companies are more likely to invest in glass recycling when it's cost-effective and efficient. This, in turn, promotes public awareness and participation in recycling efforts, creating a positive feedback loop that benefits the environment.

The impact of automatic glass breaking machines on the circular economy is significant. By facilitating the efficient recycling of glass, these machines help close the loop in glass production, moving us closer to a zero-waste model. This circularity not only reduces waste but also creates jobs in the recycling and remanufacturing sectors, contributing to sustainable economic growth.

Conclusion

Automatic glass breaking machines have truly revolutionized the recycling industry, offering a blend of efficiency, safety, and environmental benefits that were previously unattainable. As we continue to grapple with the challenges of waste management and resource conservation, these machines stand as a testament to the power of innovative technology in addressing environmental issues.

The future of glass recycling looks bright, with ongoing advancements in automatic glass breaking technology promising even greater efficiencies and capabilities. As these machines become more widespread and sophisticated, we can expect to see further increases in glass recycling rates, reductions in energy consumption, and a diminishing reliance on landfills for glass disposal.

For businesses and municipalities looking to upgrade their recycling capabilities, investing in automatic glass breaking machines is a forward-thinking decision. It's a step towards more sustainable operations, improved resource management, and a cleaner, greener future.

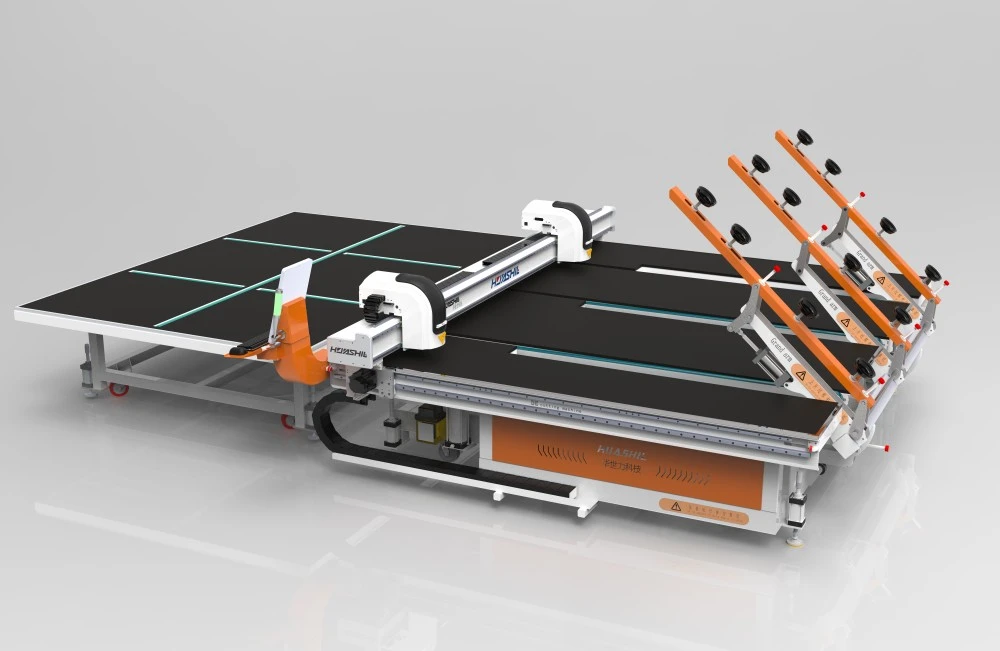

Are you ready to revolutionize your glass recycling process? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge automated solutions for the recycling industry. Our advanced automatic glass breaking machines are designed to meet the needs of modern recycling facilities, offering unparalleled efficiency, precision, and reliability. With years of experience in R&D, manufacturing, and export, we deliver high-quality equipment that's trusted by customers worldwide. Take the first step towards a more sustainable future – contact us today at salescathy@sdhuashil.com to learn how our automatic glass breaking machines can transform your recycling operations.

References

1. Johnson, E. (2022). "Advancements in Automated Glass Recycling Technologies". Journal of Waste Management and Recycling, 45(3), 267-281.

2. Patel, S., & Williams, R. (2023). "Environmental Impact Assessment of Automated Glass Breaking Systems in Municipal Recycling Programs". Environmental Science & Technology, 57(2), 1089-1102.

3. Zhang, L., et al. (2021). "Energy Efficiency Analysis of Glass Recycling Processes: A Comparative Study of Manual vs. Automated Breaking Methods". Energy Policy, 158, 112554.

4. Gonzalez-Torre, P., & Adenso-Diaz, B. (2022). "The Role of Automation in Enhancing Circular Economy Practices in the Glass Industry". Resources, Conservation and Recycling, 179, 106118.