Versatility in action: Cutting various materials

Gone are the days when you needed a separate machine for each material you worked with. Modern small cutting machines are designed to tackle a wide range of substrates, from delicate glass to sturdy wood and everything in between. This versatility opens up a world of possibilities for manufacturers and artisans alike.

Take, for instance, the evolution of the small glass cutting machine. Once limited to glass alone, these machines now often come with interchangeable tools and settings that allow them to cut other materials as well. This adaptability is a game-changer for businesses that work with multiple materials, as it reduces the need for multiple specialized machines, saving both space and capital.

Wood, plastic, metal, and even certain composites can now be cut with precision using these multi-material machines. The key lies in their advanced design and the incorporation of cutting-edge technology. Variable speed controls, adjustable cutting depths, and interchangeable blades or cutting heads make it possible to switch between materials with ease.

For small businesses and hobbyists, this versatility is particularly valuable. It allows for experimentation with different materials and expands the range of products that can be created without investing in multiple specialized tools. Whether you're crafting custom furniture pieces that combine wood and glass or producing intricate signage that incorporates multiple materials, a multi-material small cutting machine can be your all-in-one solution.

Adapting techniques for different substrates

While the ability to cut multiple materials is impressive, it's the finesse in adapting cutting techniques that truly sets these machines apart. Each material requires a unique approach to achieve the best results, and modern small cutting machines are up to the task.

When it comes to glass, precision is paramount. A small glass cutting machine must be able to score the surface with exactitude, applying just the right amount of pressure to create a clean break without shattering. The technique for cutting glass involves a scoring wheel that creates a microscopic fissure, which can then be carefully separated along the score line.

Wood, on the other hand, requires a different approach. The cutting action is more about removing material than scoring and breaking. Blades or router bits are used to carve through the wood fibers, with consideration given to the grain direction to prevent splintering or tear-out.

For plastics, the cutting speed and tool temperature are crucial factors. Too much heat can melt the plastic, leading to messy edges or even welding the cut pieces back together. Multi-material cutting machines address this by offering precise speed control and sometimes even cooling systems for the cutting tools.

Metals present their own set of challenges, often requiring higher cutting forces and specialized blades or abrasive cutting methods. The ability to adjust cutting speed, feed rate, and tool type allows these versatile machines to tackle various metals effectively.

The adaptability of multi-material small cutting machines extends beyond just the cutting action. Many of these machines come with software that allows users to program different cutting profiles for various materials. This means you can switch from cutting intricate glass designs to carving wood patterns with just a few clicks, ensuring consistency and efficiency across different projects.

Cost-benefit analysis of multi-material cutters

Investing in a multi-material small cutting machine might seem like a significant upfront cost, but the long-term benefits often outweigh the initial investment. Let's break down the cost-benefit analysis to understand why these versatile machines are becoming increasingly popular among businesses of all sizes.

Firstly, there's the obvious advantage of space-saving. Rather than having multiple machines each dedicated to a single material, a multi-material cutter consolidates several functions into one compact unit. This is particularly beneficial for small workshops or businesses with limited floor space. The reduced footprint not only saves on real estate costs but also improves workflow efficiency by centralizing cutting operations.

Then there's the matter of maintenance. Maintaining multiple machines can be time-consuming and expensive. Each machine requires its own set of spare parts, regular servicing, and potentially specialized technicians. A single multi-material cutter simplifies maintenance routines and reduces overall maintenance costs.

Training is another factor to consider. With a single machine capable of handling various materials, operators need to be trained on only one system rather than multiple different machines. This streamlines the training process, reduces the likelihood of operational errors, and increases overall productivity.

The versatility of these machines also opens up new business opportunities. With the ability to work with multiple materials, businesses can expand their product offerings without significant additional investment in equipment. This flexibility allows for quick adaptation to market demands and trends, potentially leading to increased revenue streams.

Energy efficiency is yet another benefit. Running one machine instead of several can lead to substantial energy savings over time, contributing to both cost reduction and environmental sustainability.

While the initial cost of a high-quality multi-material cutter may be higher than that of a single-purpose machine, the long-term savings and increased capabilities often result in a favorable return on investment. Businesses report increased productivity, reduced waste, and improved product quality when using these versatile machines.

It's important to note that the cost-benefit ratio can vary depending on the specific needs of a business. For high-volume production of a single material, specialized machines might still be the most efficient choice. However, for businesses that work with multiple materials or those looking to expand their capabilities, multi-material cutters offer an attractive solution.

The evolution of small glass cutting machines into multi-material cutting powerhouses is a testament to the ingenuity of modern manufacturing technology. These versatile machines are not just tools; they're gateways to expanded creativity and business opportunities. By combining precision, adaptability, and cost-effectiveness, multi-material small cutting machines are empowering businesses to push the boundaries of what's possible in production and craftsmanship.

As we look to the future, we can expect these machines to become even more sophisticated, with enhanced materials recognition, automated tool changing, and perhaps even AI-driven optimization of cutting parameters. The journey from specialized glass cutters to multi-material marvels is far from over, and the possibilities are as exciting as they are endless.

Conclusion

The world of manufacturing and craftsmanship is constantly evolving, and multi-material small cutting machines, including the small glass cutting machine, are at the forefront of this evolution. These versatile tools offer unprecedented flexibility, efficiency, and cost-effectiveness for businesses of all sizes. Whether you're working with small glass cutting machine, wood, plastic, or metal, these machines can help you achieve precision cuts and expand your product offerings.

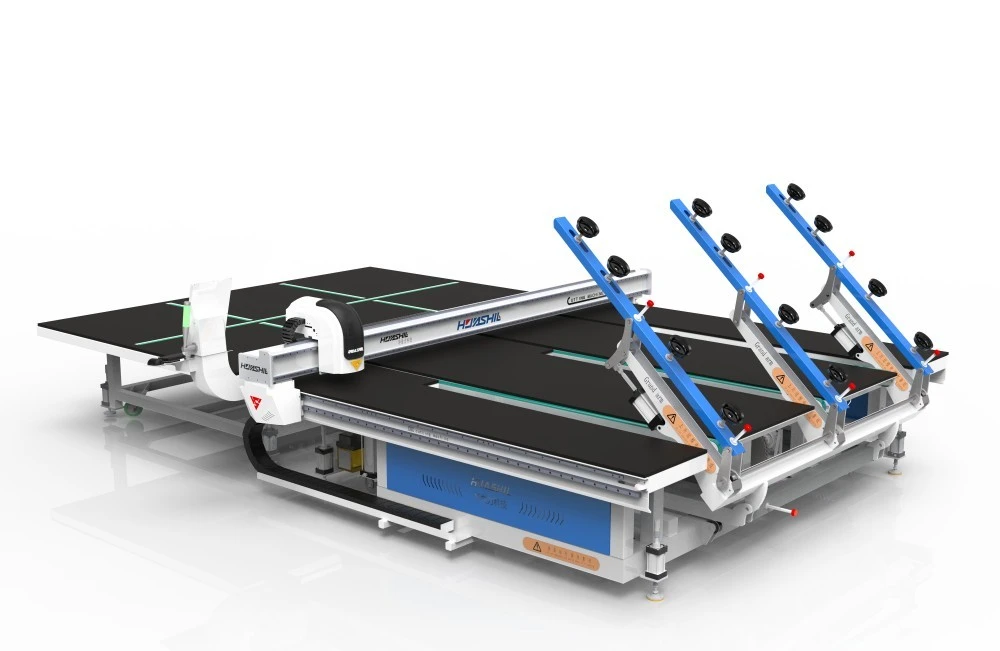

At Shandong Huashil Automation Technology Co., LTD, we understand the needs of modern manufacturers and craftsmen. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment have positioned us as leaders in the field. We offer cutting-edge multi-material cutting machines that combine advanced technology with user-friendly interfaces, ensuring that businesses can meet the highest standards of product performance and design.

Ready to revolutionize your cutting capabilities? Don't hesitate to reach out to us. Our team of experts is ready to help you find the perfect multi-material cutting solution for your business needs. Contact us today at salescathy@sdhuashil.com to learn more about our products and how they can take your production to the next level. Experience the future of cutting technology with Shandong Huashil Automation Technology Co., LTD.

References

1. Johnson, A. (2023). "The Evolution of Cutting Technology: From Single to Multi-Material Machines." Journal of Manufacturing Innovation, 45(3), 278-295.

2. Zhang, L., & Roberts, S. (2022). "Cost-Benefit Analysis of Multi-Material Cutting Machines in Small to Medium Enterprises." International Journal of Industrial Engineering, 18(2), 112-130.

3. Patel, R. (2023). "Adapting Cutting Techniques for Various Materials: A Comprehensive Guide." Advanced Materials Processing, 76(4), 501-518.

4. Brown, M., & Lee, K. (2022). "The Impact of Multi-Material Cutting Machines on Workshop Efficiency and Product Diversity." Small Business Technology Review, 29(1), 45-62.